Multi-pose rain test system for vehicle body

A test system and multi-position technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of incomplete detection of body sealing performance, prolong the test cycle, affect the quality of the body, etc., and shorten the rain test. Period, test results are accurate, and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

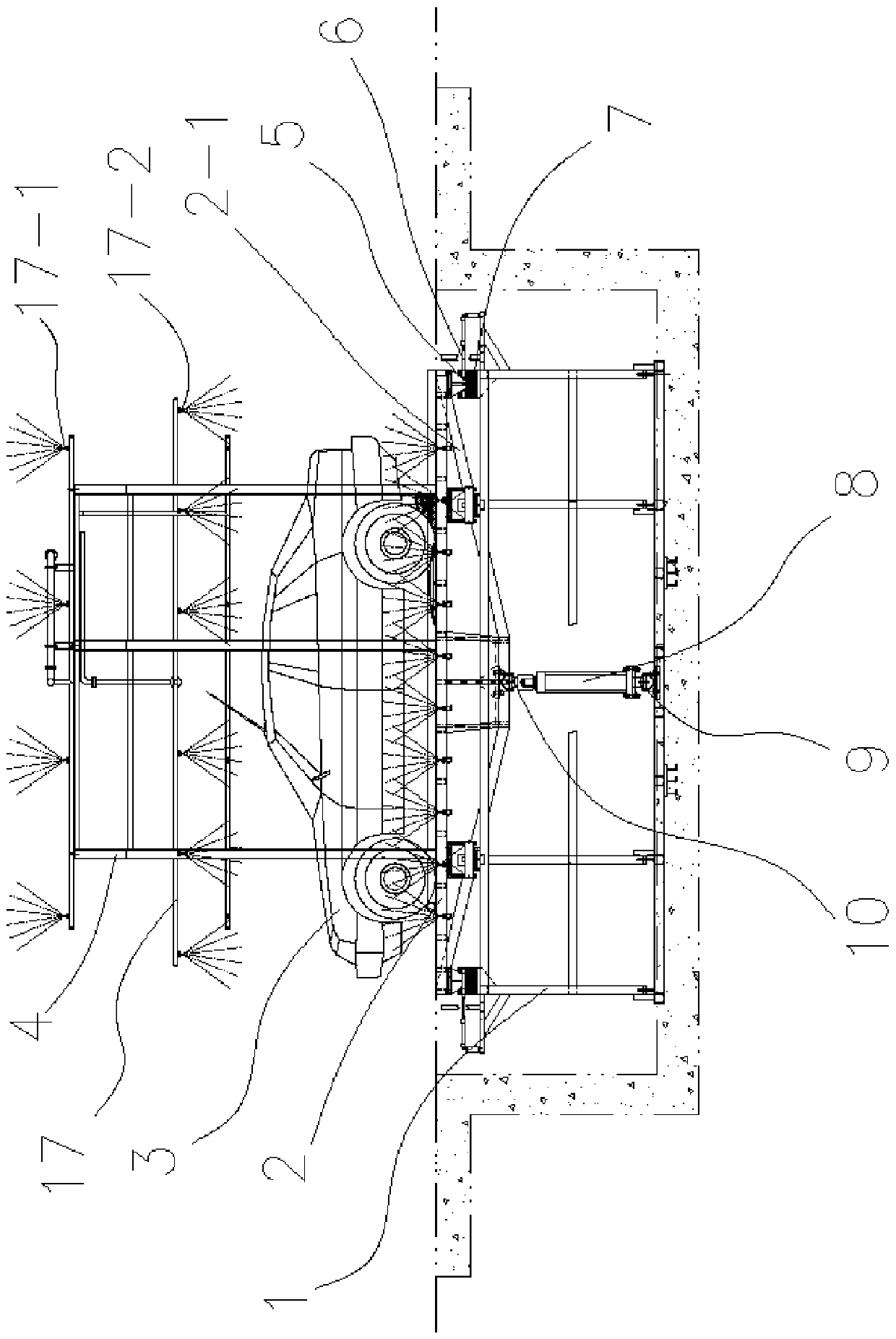

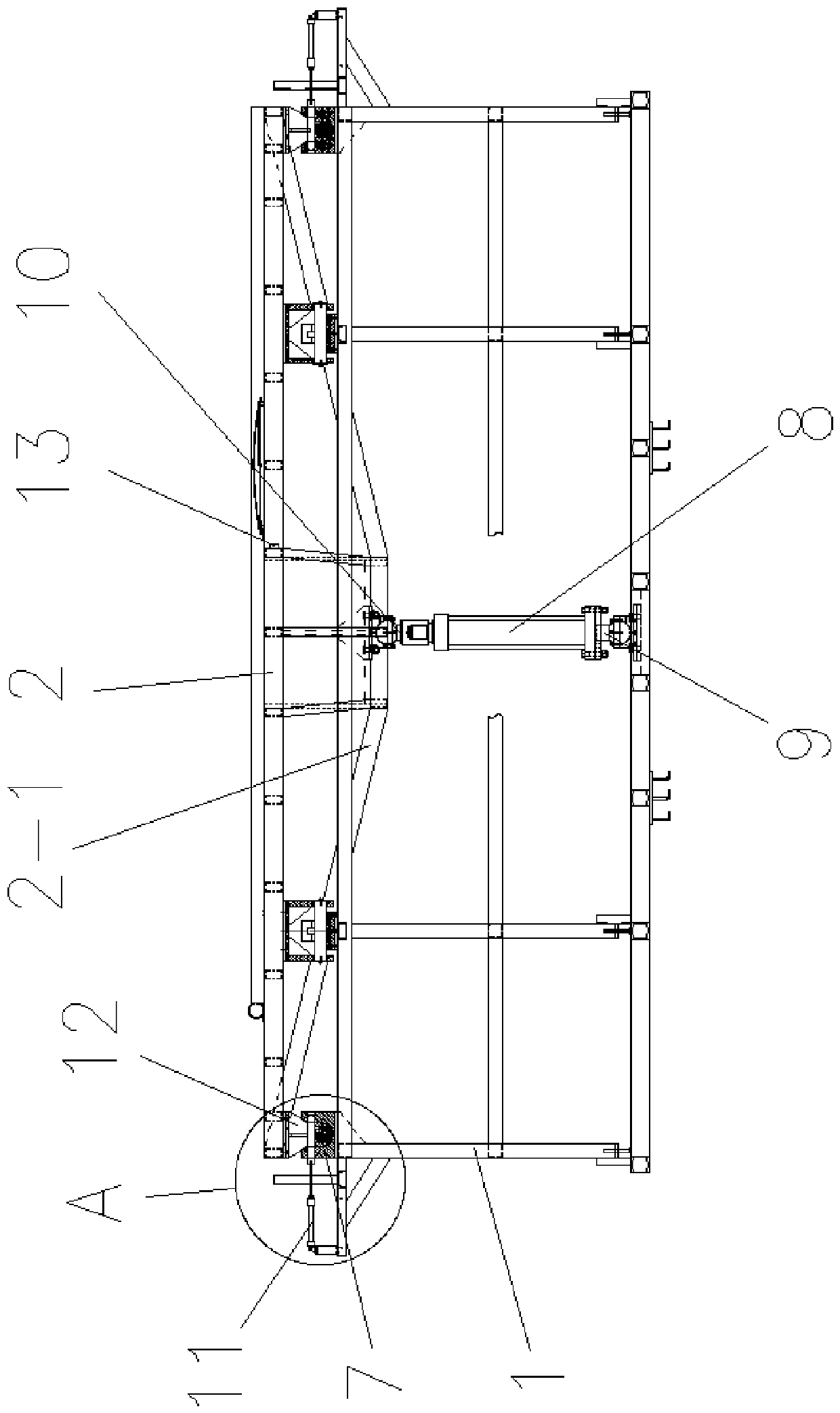

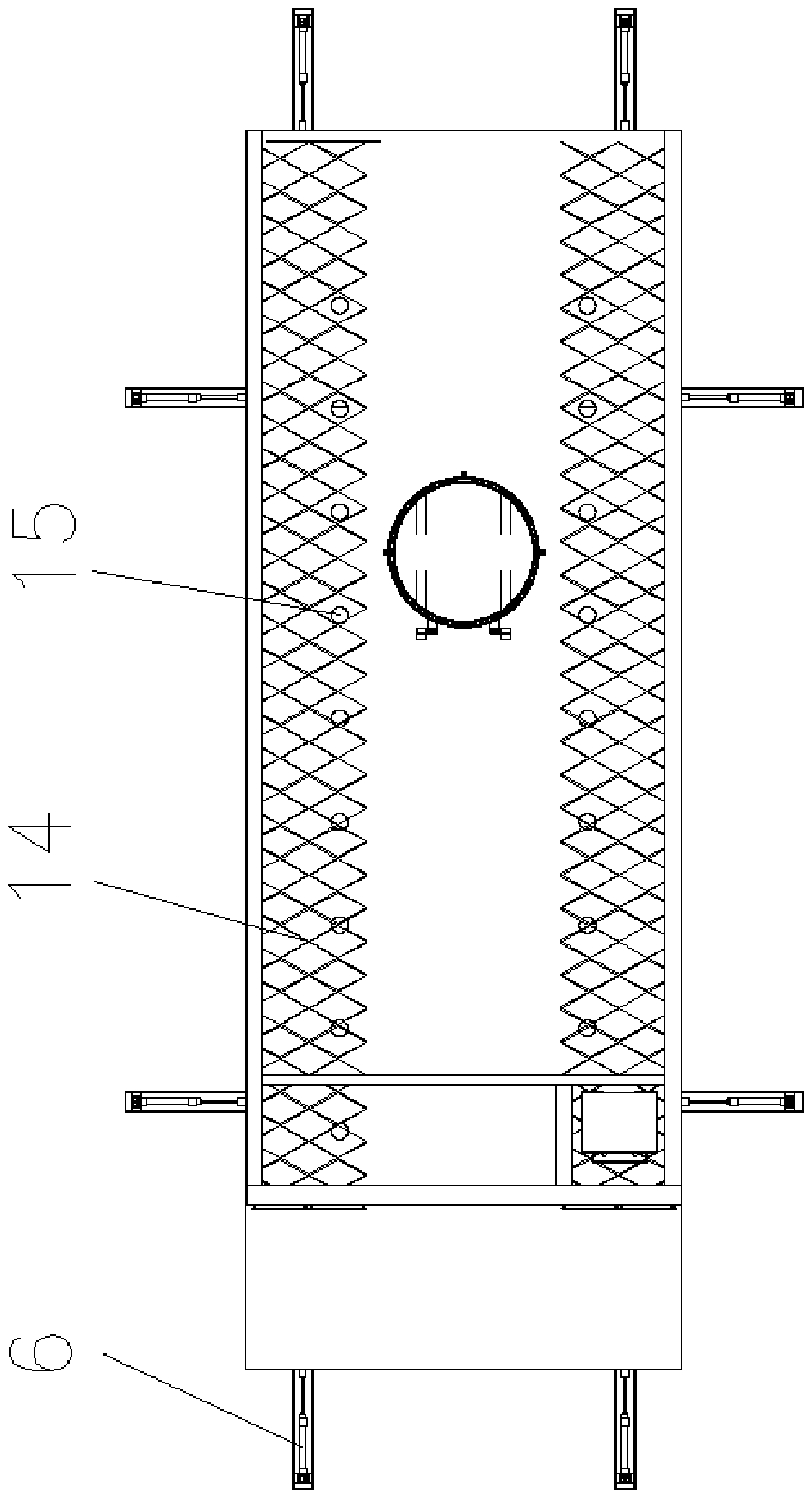

[0036] see Figure 1 to Figure 7 , a vehicle body multi-position rain test system, including a spray system, an underframe 1, the underframe 1 is welded by stainless steel profiles. The upper end surface of the underframe 1 is a rectangular frame, and a rectangular movable platform 2 for supporting the vehicle body 3 is located in the rectangular frame. The movable platform 2 is welded by stainless steel profiles, and the upper end surface of the movable platform 2 is laid with a stainless steel plate, and the stainless steel plate is welded with anti-skid steel bars. carry out testing. Automobile needs to use anti-slip pillow and wheel strap to fix vehicle body after driving on movable platform 2, prevents vehicle body from sliding and shifting when movable platform 2 tilts. The lower end of the movable platform 2 is provided with a mounting frame 2-1, and the center of the lower end of the movable platform 2 is provided with a jacking hydraulic cylinder 8, and the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com