Ultra-supercritical boiler closed-loop combustion optimal control method

An ultra-supercritical boiler and combustion optimization technology, which is applied in the direction of combustion methods, combustion control, and fuel supply adjustment, can solve the problems of lack of adaptability to changing factors such as coal types, reduce the amount of online calculations, and fail to adapt to changes in coal types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0139] The technical solution of the present invention will be further introduced below in combination with specific implementation methods and accompanying drawings.

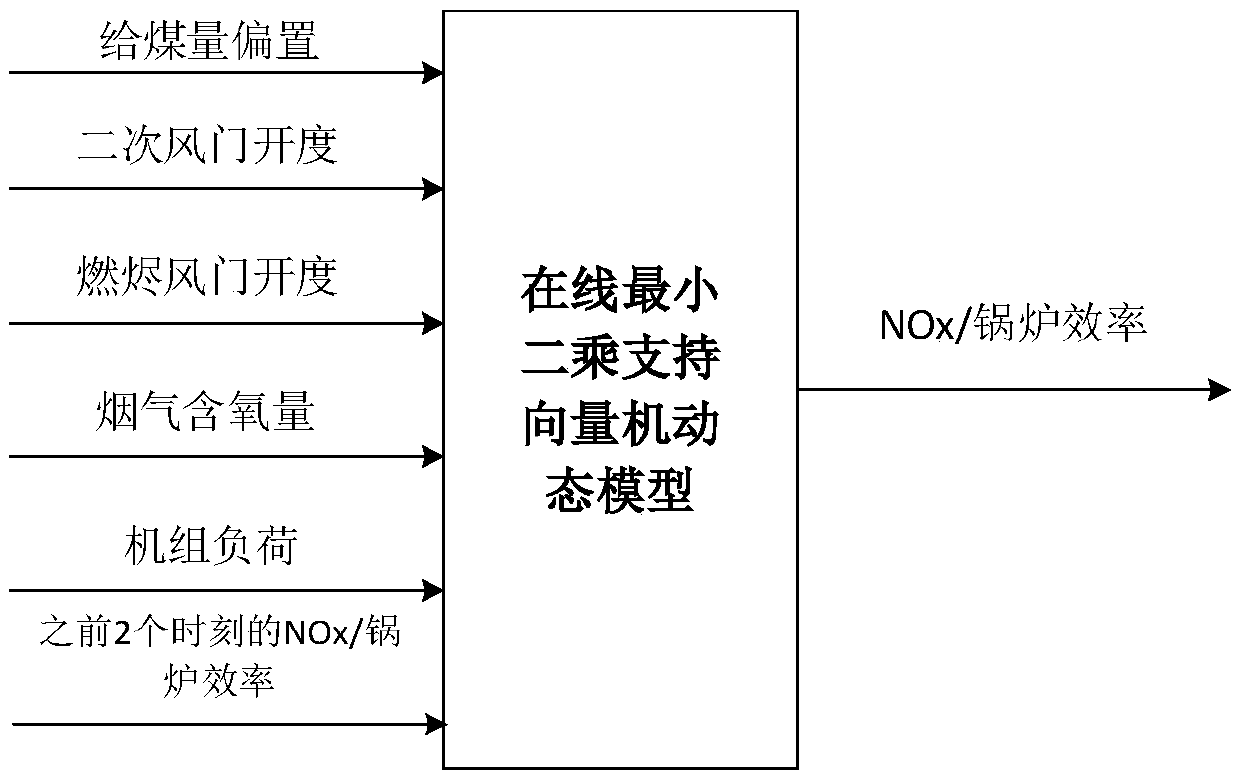

[0140] This specific embodiment discloses a closed-loop combustion optimization control method for an ultra-supercritical boiler. figure 1 A schematic diagram of the method, the method includes the following steps:

[0141] S1: Establish a boiler efficiency prediction model and a NOx concentration prediction model, and respectively calculate the boiler efficiency prediction value and NOx concentration prediction value at the current k time according to the two prediction models;

[0142] S2: Compare the two predicted values at the current moment k obtained in step S1 with their respective measured values, and judge whether the deviation meets the accuracy requirements: if not, update the model parameters and sample data, and then proceed to step S3; if If the accuracy is satisfied, proceed to step S3;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com