SHRT unit frequency converter and steam turbine rotating speed synchronous automatic adjusting control method

A unit frequency converter and automatic adjustment technology, applied in the direction of machine/engine, pump control, engine starting, etc., can solve the problems of current reduction, DC bus voltage increase, unit interlock shutdown, etc., to achieve stable motor current, The effect of saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

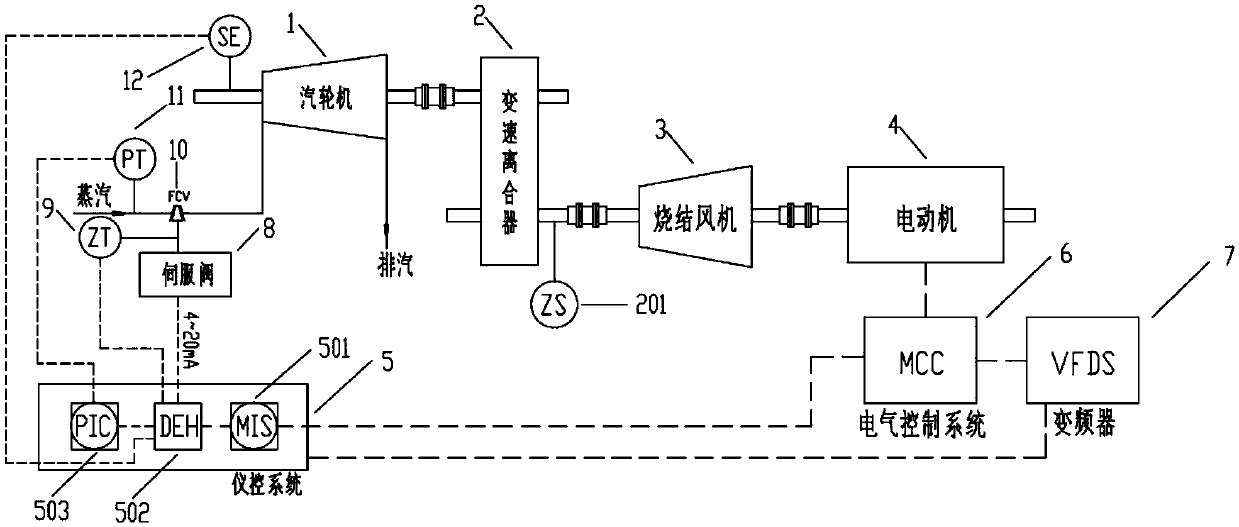

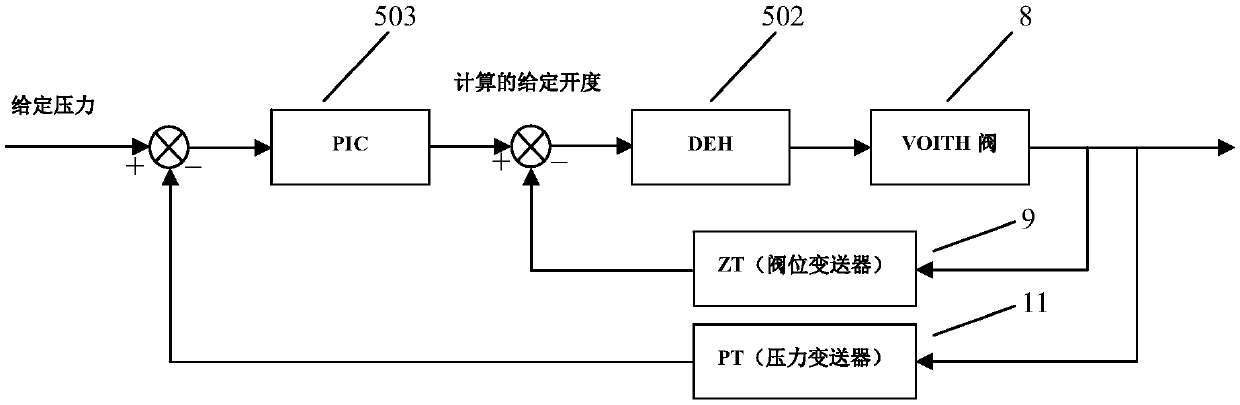

[0027] The present invention first analyzes the problems encountered by the unit in the process of frequency conversion and speed regulation through the research on the process system of the sintering waste heat recovery and the sintering fan combined drive unit, and the research on the working principle of the motor and its supporting frequency converter, and proposes a speed regulation control method for the unit.

[0028] The following is an analysis of the problems that may be encountered during the speed regulation of the variable frequency SHRT unit according to the attached drawings: When the unit has started and is running normally, due to changes in working conditions (such as a decrease in the demand for sintering exhaust air volume), the unit needs to reduce the speed Running, the deceleration process is dominated by the motor 4, and the steam turbine 1 cooperates with the speed regulation. Assuming that the steam turbine 1 does not participate in the coordination adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com