Concrete pouring pump pipe bracket

A technology of concrete and pump pipes, which is applied in the field of supports, can solve problems such as construction safety, hidden dangers in quality, poor stability of pump pipes, cracking of pump pipe joints, etc., and achieve the effects of reducing engineering costs, stabilizing the structure, and avoiding pipe bursts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

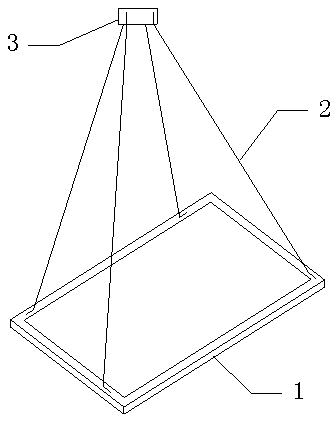

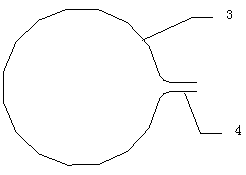

[0029] The concrete pouring pump pipe support of the present invention includes a centralizing seat and a buffer frame. The construction process of the concrete pouring pump pipe support of the present invention is as follows: determine the diameter of the pump pipe bend and the length of the straight pipe section → make the rectangular square tube base of the pump pipe support → locate the position of the outrigger of the buffer frame → cut and weld the leg reinforcement and skeleton reinforcement → Fix the buffer frame on the square tube of the base → make the pump pipe hoop → locate the position of the pump pipe hoop of the buffer frame → weld the positioning rib of the pipe hoop → locate the position of the pump pipe hoop of the centralizing frame → weld the positioning rib of the pump pipe hoop of the centralizing frame → Insert the pump tube → fasten the pump tube clamp → put into use.

[0030] see now figure 1 , figure 1 It is a structural schematic diagram of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com