Microbial mineralized cementation treatment liquid and sandy slope treatment method

A technology of microorganisms and treatment liquid, which is applied in the treatment of sandy slopes and the field of microbial mineralization cementation treatment liquid, can solve the problems of low survival rate of grass planting, endangering the environment, endangering driving safety, etc., achieving broad application prospects and improving cementing ability. , The effect of preventing erosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

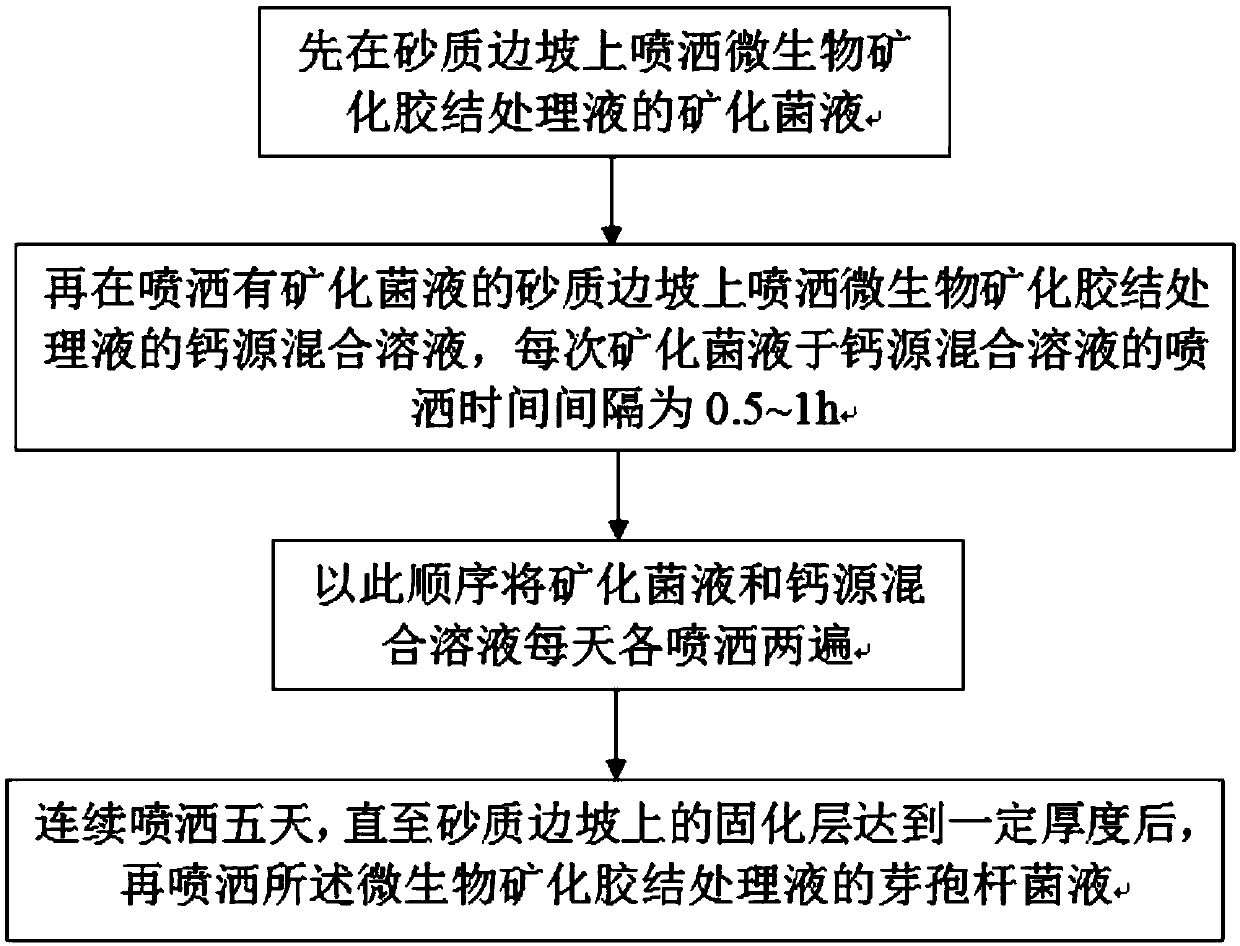

[0037] For the control method of sandy and easily eroded sandy slopes of the present invention, please refer to figure 1 , including the following steps:

[0038] Provide a microbial mineralization and cementation treatment liquid for treating sandy slopes;

[0039] First spray the mineralizing bacteria liquid of the microbial mineralization cementation treatment liquid on the sandy slope;

[0040] Then spray the calcium source mixed solution of the microbial mineralization cementation treatment solution on the sandy slope sprayed with the mineralization bacteria solution;

[0041] In this order, the mineralizing bacteria liquid and the calcium source mixed solution are sprayed twice a day, and the time interval between the spraying of the mineralizing bacteria liquid and the calcium source mixed solution is 0.5-1 h each time, and the continuous spraying Five days until the solidified layer on the sandy slope reaches a certain thickness (such as 5cm ~ 10cm), then spray the ...

Embodiment 2

[0054] In this embodiment, the microbial mineralization and cementation treatment solution is composed of a mineralization bacteria treatment solution with mineralization ability and a Bacillus treatment solution with cementation and cohesion ability, and the preparation of the microbial mineralization and cementation treatment solution includes the following steps. Step 1: Prepare the mineralizing bacteria liquid.

[0055] The 2# strain of the mineralizing bacteria is domesticated and cultivated in the culture medium for 3 to 4 times, each time it is connected to the culture medium according to the inoculum amount of 1% to 5%, each time for 24h to 48h, and the culture temperature is 30°C to 30°C. 40°C, 180-200r / min, pH 6.0-6.5, culture time 2d-4d.

[0056] The 2# bacterial liquid culture medium is composed of 12~18g / L yeast powder, 0.05~0.1mol / L NH 4 Cl, 0.1~0.5mol / L CO(NH 2 ) 2 composition.

[0057] Step 2: Prepare calcium source mixed solution.

[0058] The calcium sou...

Embodiment 3

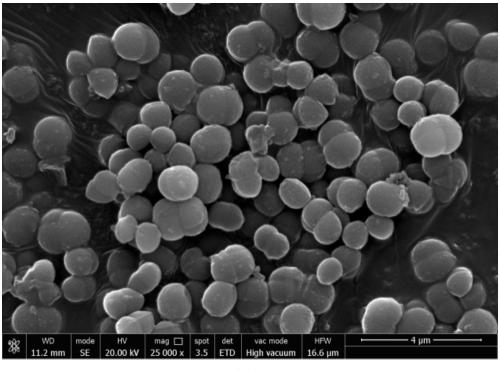

[0072] Mineralizing bacteria (CGMCC No.15633) frozen in a low-temperature refrigerator, see image 3 , and directly poured into the fresh medium (12~18g / L yeast powder, 0.05~0.1molNH 4 Cl, 0.1~0.5molCO(NH 2 ) composition) cultured for 48h, culture temperature 30°C, 200r / min, initial pH value, each time according to the inoculum amount of 1%, inoculated into the new medium, activated culture 3 to 4 times, each 48h, and then according to the required protection For the area of the slope, expand the cultured bacteria solution, and prepare the activated bacteria solution with an OD600 value of 1.0 to 1.5. The main calcium source of calcium source mixed solution is calcium chloride, the concentration of calcium ion is 0.5mol, and 0.2mol~0.35mol NH 4 Cl, 3%~5% Nutrient Broth, 0.5mol~0.8molCO(NH 2 ) 2 , 0.1mol~0.2mol NaHCO 3 and running water.

[0073] The volume ratio of the mineralizing bacteria solution used to the bacillus solution with cementing ability and the treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com