Anchor sealing material suitable for anchor cable in turbulent region

An anchor cable and water flow technology, which is applied in the field of water conservancy and hydropower engineering, can solve the problems of anchor cable anchor force loss, poor durability, and low bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

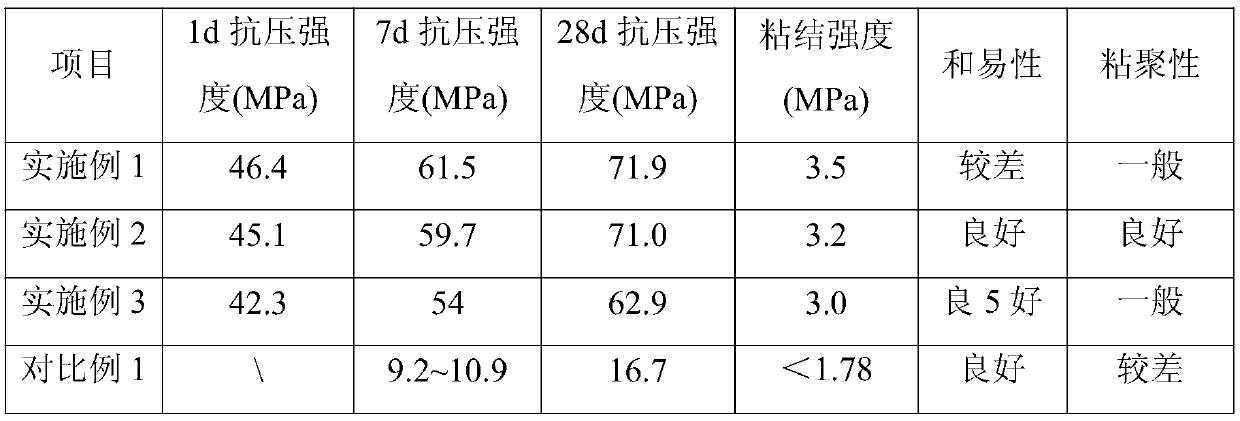

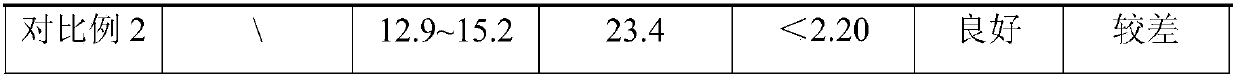

Examples

preparation example Construction

[0030] The present invention also provides the preparation method of the above-mentioned anchoring material suitable for the anchor cable in the water flow turbulent zone, comprising the following steps:

[0031] A. Heat the epoxy resin at a temperature of 70-100°C for 3-5 minutes until it becomes glue-like;

[0032] B, add ethylenediamine and acetone in the glue-like epoxy resin that step A makes, mix homogeneously, obtain mixture A;

[0033] C, add cement and fine aggregate in the mixture A that step B makes, mix evenly, get viscous mixture B;

[0034] D. Add coarse aggregate to the mixture B prepared in step C, and mix evenly to obtain the anchor material suitable for the anchor cable in the water flow turbulent zone.

[0035] In order to ensure that each material is fully mixed, in step B, the time for uniform mixing is 2 to 5 minutes; in step C, the time for uniform mixing is 5 to 10 minutes; in step D, the time for uniform mixing is 5 to 5 minutes. 10min.

[0036] The...

Embodiment 1

[0039] The anchor material of the present embodiment includes the following raw materials in parts by weight: 205 parts of epoxy resin, 82 parts of ethylenediamine, 51 parts of acetone, 350 parts of cement, 685 parts of fine aggregate and 1027 parts of coarse aggregate;

[0040] The particle size of the fine aggregate is 0-5 mm; the particle size of the coarse aggregate is 5-15 mm;

[0041] The fine aggregate and coarse aggregate should be washed with clean water before use, and fully dried or dried, with a mud content of no more than 1.0% and a moisture content of no more than 0.5%.

[0042] The preparation method of anchor sealing material comprises the following steps:

[0043] A. Heat at 75°C for 5 minutes to make the epoxy resin into a glue-like shape;

[0044]B, add ethylenediamine, acetone to the glue-like epoxy resin that step A makes, fully mix and stir 5min, obtain mixture A;

[0045] C. Add cement and fine aggregate to the mixture A prepared in step B, fully mix a...

Embodiment 2

[0048] The anchor sealing material of this embodiment includes the following raw materials in parts by weight: 205 parts of epoxy resin, 82 parts of ethylenediamine, 51 parts of acetone, 350 parts of cement, 856 parts of fine aggregate and 856 parts of coarse aggregate;

[0049] The particle size of the fine aggregate is 0-5 mm; the particle size of the coarse aggregate is 5-15 mm;

[0050] The fine aggregate and coarse aggregate should be washed with clean water before use, and fully dried or dried, with a mud content of no more than 1.0% and a moisture content of no more than 0.5%.

[0051] The preparation method of anchor sealing material comprises the following steps:

[0052] A. Heat at 90°C for 4 minutes to make the epoxy resin into a glue-like shape;

[0053] B, add ethylenediamine, acetone to the glue-like epoxy resin that step A makes, fully mix and stir 5min, obtain mixture A;

[0054] C. Add cement and fine aggregate to the mixture A prepared in step B, fully mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com