Method for treating circulating cooling water of high-speed trains

A technology for circulating cooling water and treatment methods, applied in water/sludge/sewage treatment, special treatment targets, chemical instruments and methods, etc., can solve the problems of accelerated corrosion and prone to corrosion, and achieve rapid treatment and efficient methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] According to one embodiment, the total iron content of the high-speed iron circulating cooling water is 2.0-3.0 mg / L.

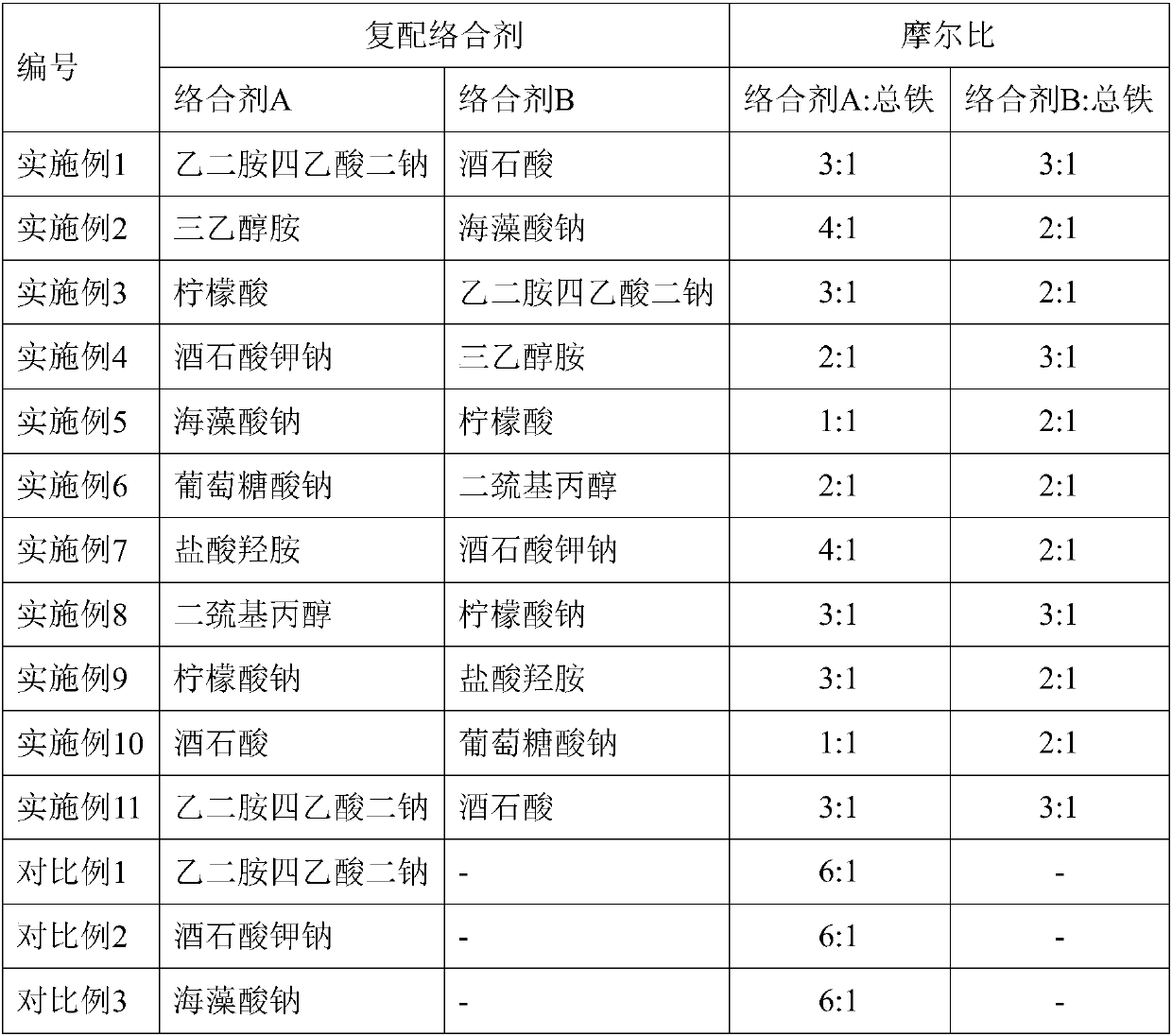

[0018] In this embodiment, the complexing agent is selected from one of the following combinations: disodium edetate and tartaric acid, citric acid and disodium edetate, triethanolamine and sodium alginate, Tartrate and Triethanolamine, Sodium Alginate and Citric Acid, Sodium Gluconate and Dimercaptopropanol, Hydroxylamine Hydrochloride and Tartrate, Dimercaptopropanol and Citrate, Citrate and Hydroxylamine Hydrochloride, Tartaric Acid and Sodium Gluconate.

[0019] Preferably, the complexing agent is selected from one of the following combinations: triethanolamine and sodium alginate, tartrate and triethanolamine, sodium alginate and citric acid, hydroxylamine hydrochloride and tartrate, tartaric acid and sodium gluconate , which can further reduce the corrosion of high-speed rail circulating cooling water.

[0020] More preferably, the complexing ag...

Embodiment 1-10 and comparative example 1-3

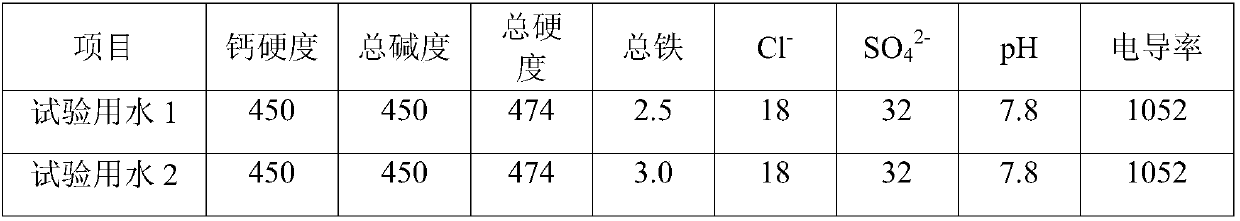

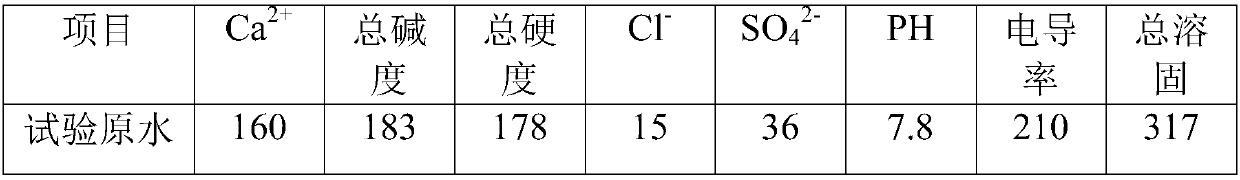

[0050] Add compound complexing agent (composed of complexing agent A and complexing agent B) to test water 1 and test water 2 respectively, and add scale and corrosion inhibitor 1 to In test water 1 and 2, the effective concentrations of PBTCA, HEDP, and terpolymer in the water are respectively 4mg / L, 4mg / L, and 8mg / L. As shown in table 2.

Embodiment 11

[0052] Process test water 1 and 2 according to the method of Example 1, the difference is that the scale and corrosion inhibitor 2 of the same quality is used to replace the scale and corrosion inhibitor 1 of Example 1, so that sodium hexametaphosphate, HPAA and binary The effective concentrations of the copolymers are 4mg / L, 4mg / L and 8mg / L respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Adhesion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com