Automatic soft-to-soft flexible attaching machine and attaching process thereof

A soft and flexible, laminating machine technology, applied in lamination device, lamination auxiliary operation, lamination and other directions, can solve problems such as easily affecting FILM placement or lamination, FILM film damage, interrupted film tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

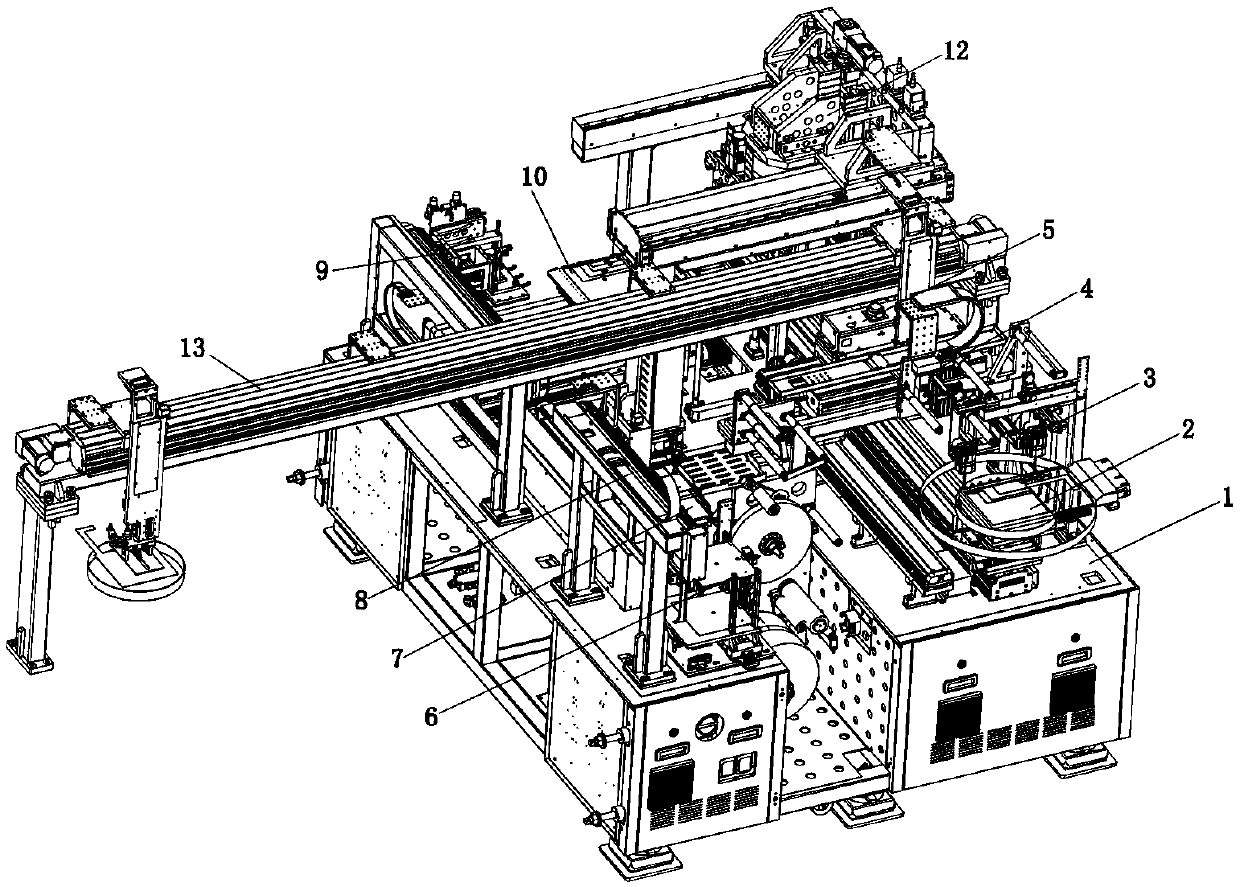

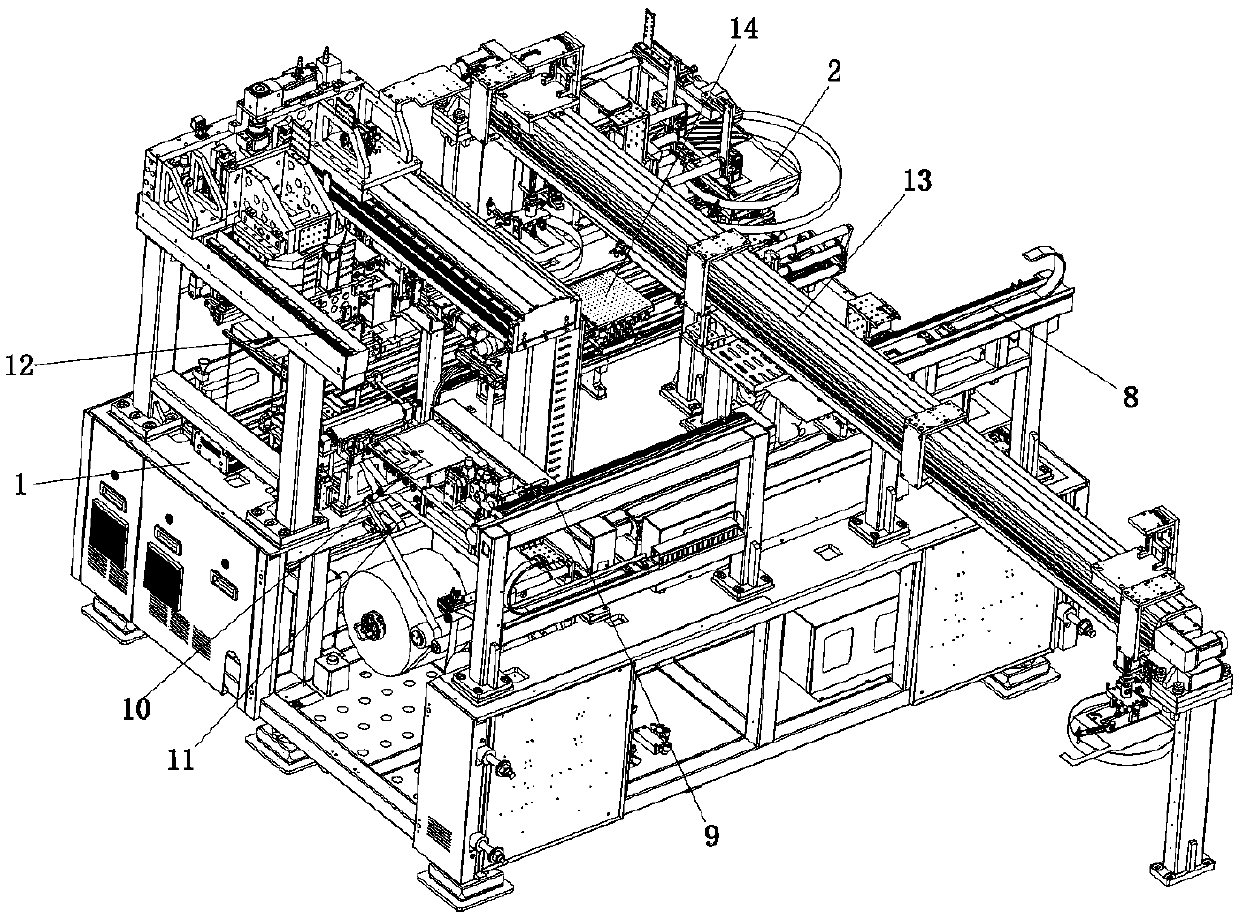

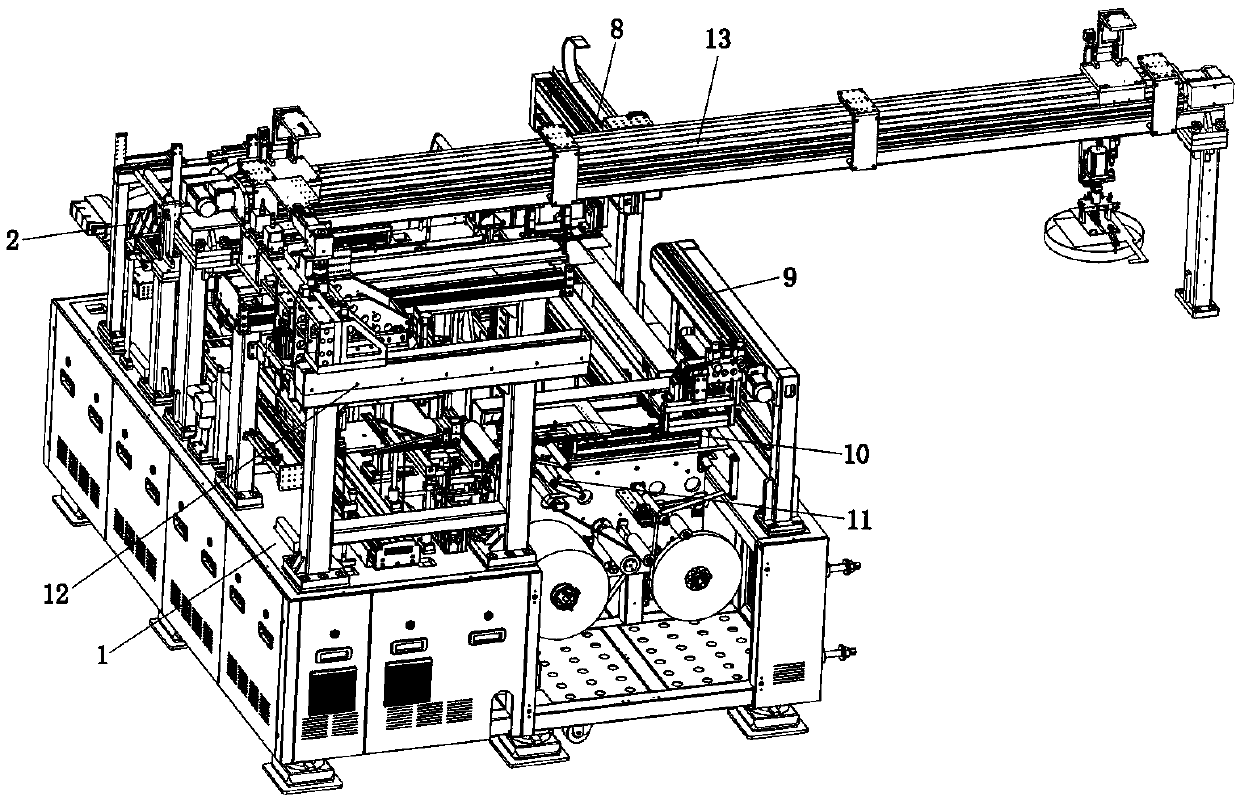

[0095] The present invention will be further described below in conjunction with accompanying drawing:

[0096] Such as Figure 1 to Figure 41 As shown, the technical scheme adopted by the present invention is as follows: an automatic soft-to-soft flexible laminating machine, including OLED adsorption and transfer platform 2, OLED film tearing mechanism 4, FILM film feeding mechanism 6, FILM film transfer platform 7, the first A transport arm 8, a second transport arm 9, a FILM film tearing mechanism and a laminating mechanism 12, wherein the above-mentioned OLED adsorption and transfer platform 2 and the FILM film transfer platform 7 are horizontally arranged on the frame 1 along the same direction, The OLED film to be torn off and pasted is placed on the OLED adsorption and transfer platform 2, and moves backward in a straight line after being initially positioned by the OLED adsorption and transfer platform 2;

[0097] The above-mentioned OLED film tearing mechanism 4 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com