Split-type multi-purpose pouring device

A multi-purpose, split-type technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of poor installation adaptability, difficulty in balancing production, quality, and cost, etc., to reduce work intensity, production and The quality and cost are highly consistent and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

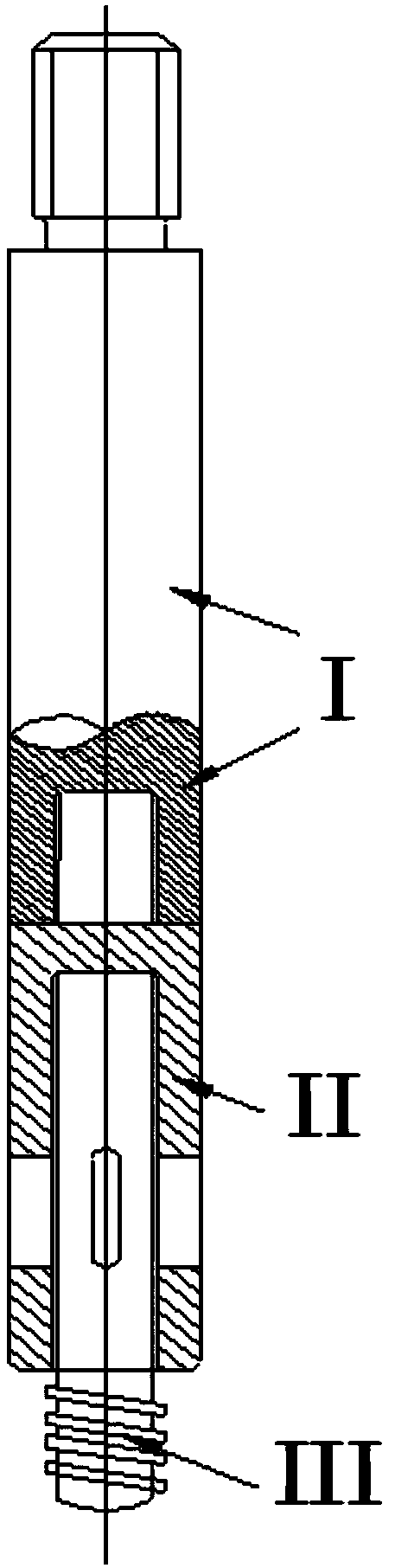

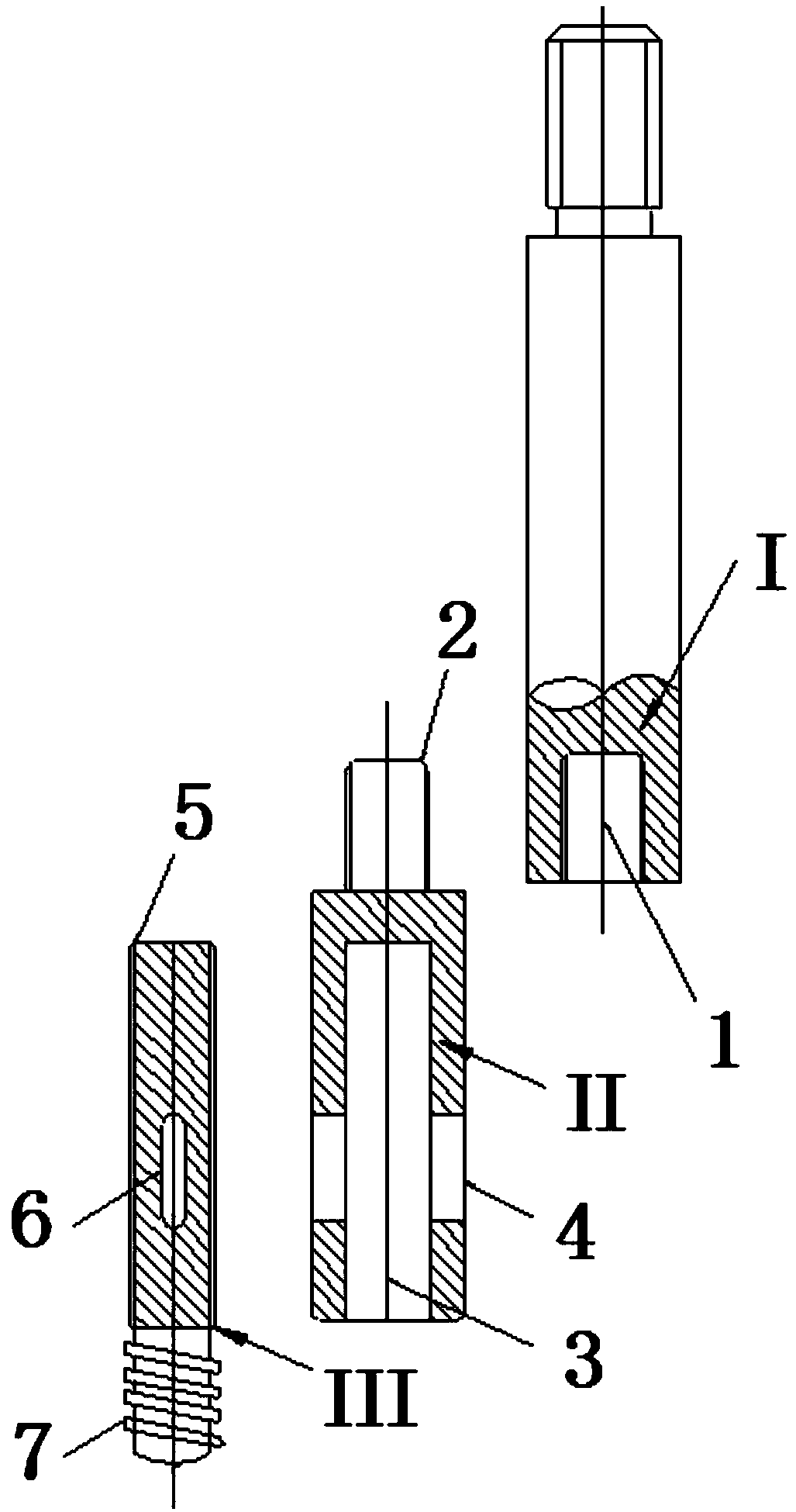

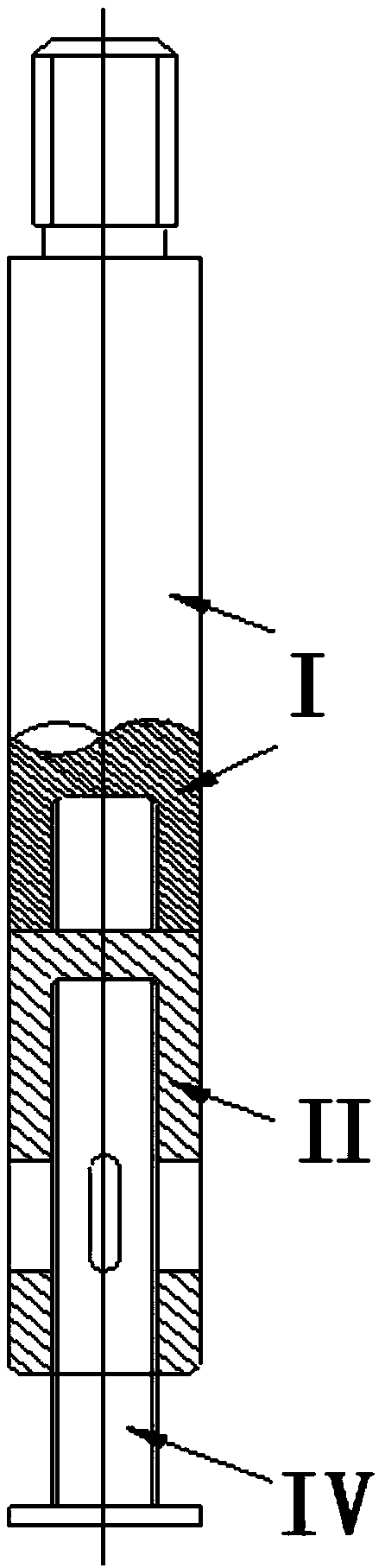

[0020] refer to figure 1 , image 3 , the structure of the present invention is that it includes the iron core body I and the iron core split body II which are threaded in sequence, and the lower end of the iron core split body II is threaded with the screw connecting body III or the bolt connecting body IV;

[0021] refer to figure 1 , figure 2 , the structure of the screw connection mode of the present invention is that the iron core body embedded screw hole 1 (i.e. the inner screw hole) is processed at the iron core body I bottom, and the iron core split body screw 2 (i.e. the inner screw hole) is processed at the iron core split body II top. external thread), the iron core split screw 2 is threadedly connected with the inner screw hole 1 of the iron core body, and the iron core split inner screw hole 3 (internal thread hole) is proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com