Machining method of bi-metal composite roller sleeve and bi-metal composite roller sleeve

A processing method and technology of composite rollers, applied in the processing of bimetal composite roller sleeves and the field of bimetal composite roller sleeves, can solve the problems of incomplete bonding, gaps in the bonding layer, impurities in the bonding layer, etc., and achieve complete fusion and good bonding. , good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

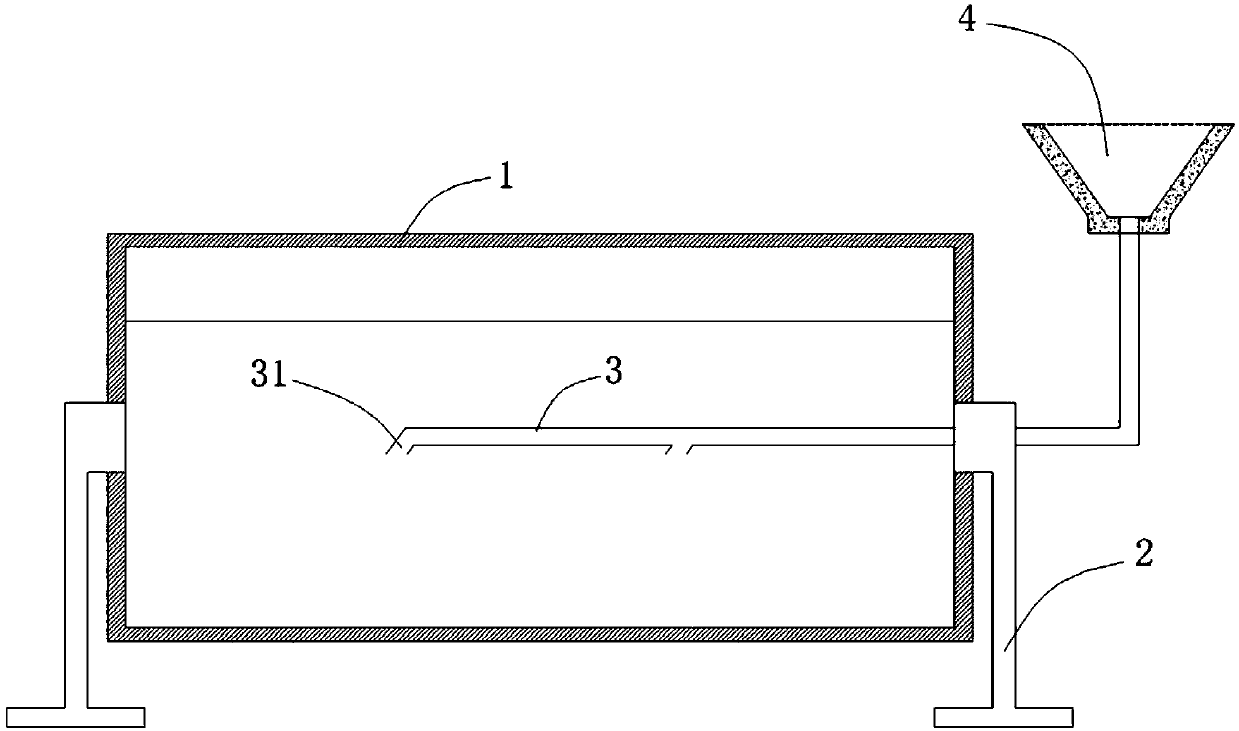

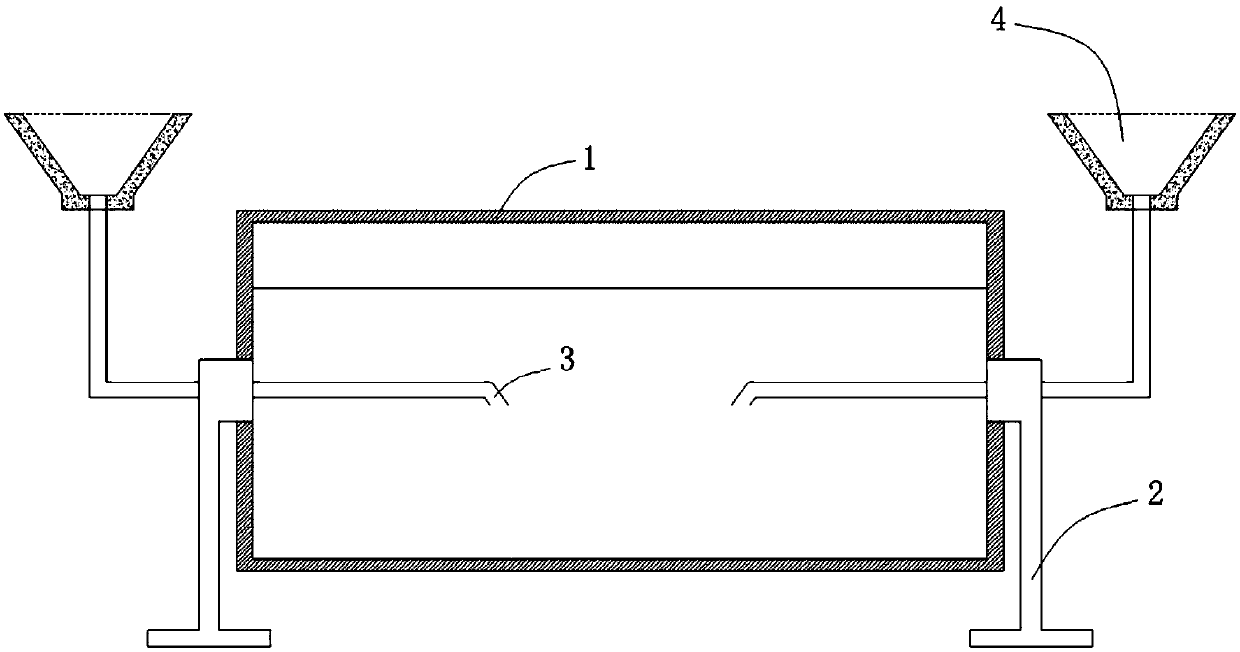

[0035] Please refer to figure 1 and figure 2 , the processing method of a kind of bimetal composite roll sleeve of the present embodiment, this processing method comprises the following steps:

[0036] (a), erect the pre-prepared outer steel mold 1 on the centrifugal rotation mechanism 2, make the axis of the outer steel mold 1 in a horizontal state, and extend the casting nozzle 3 from one end of the outer steel mold 1 into the outer steel mold 1 Inside, the casting nozzle 3 can be controlled to move axially in the outer steel mold 1 , and the casting nozzle 3 communicates with the casting cup 4 .

[0037] (b) Turn on the centrifugal rotating mechanism 2, set the rotating speed of the centrifugal rotating mechanism 2 to 750-1200 rpm, and the centrifugal rotating mechanism 2 drives the outer steel mold 1 to rotate.

[0038] (c), first cast the outer layer 101 of the composite roller sleeve, after casting the outer layer 101 of the roller sleeve to the designed thickness, co...

Embodiment 2

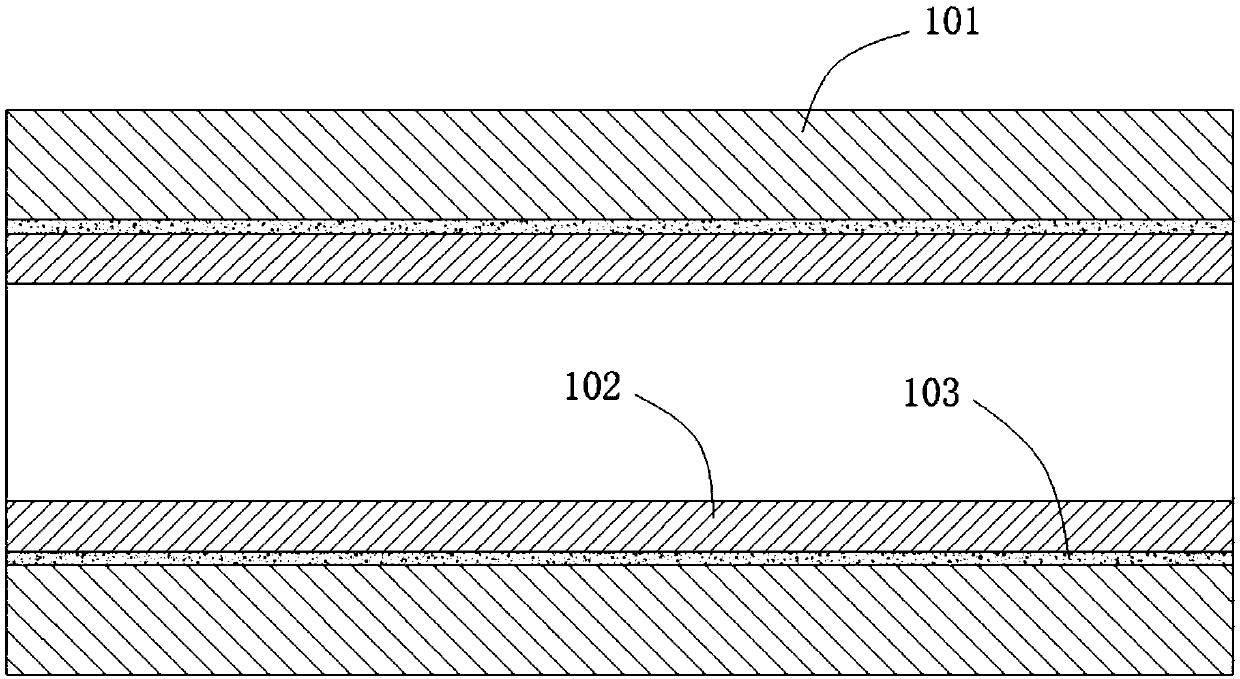

[0050] Please refer to image 3 , a bimetallic composite roller sleeve of this embodiment is manufactured using the processing method described in Embodiment 1, and the bimetallic composite roller sleeve includes: an outer layer 101 of a roller sleeve, an inner layer 102 of a roller sleeve and a fused transition layer 103 , the outer layer 101 of the roller sleeve is a high-speed alloy steel outer layer formed by centrifugal casting, the inner layer 102 of the roller sleeve is an inner layer of low-carbon steel formed by centrifugal casting, and the fusion transition layer 103 is made of low-carbon steel when casting the inner layer 102 of the sleeve The transition layer is formed by mutual fusion between molten high-speed alloy steel and molten high-speed alloy steel in the outer layer 101 of the sleeve.

[0051] Preferably, the thickness of the fused transition layer 103 is 5-15 mm, the thickness of the outer layer 101 of the roll sleeve is 5-10 times the thickness of the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com