Battery cleaning device

A technology for cleaning devices and batteries, applied in the directions of dry gas arrangement, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of battery insulation performance, poor versatility, and inability to meet battery cleaning and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

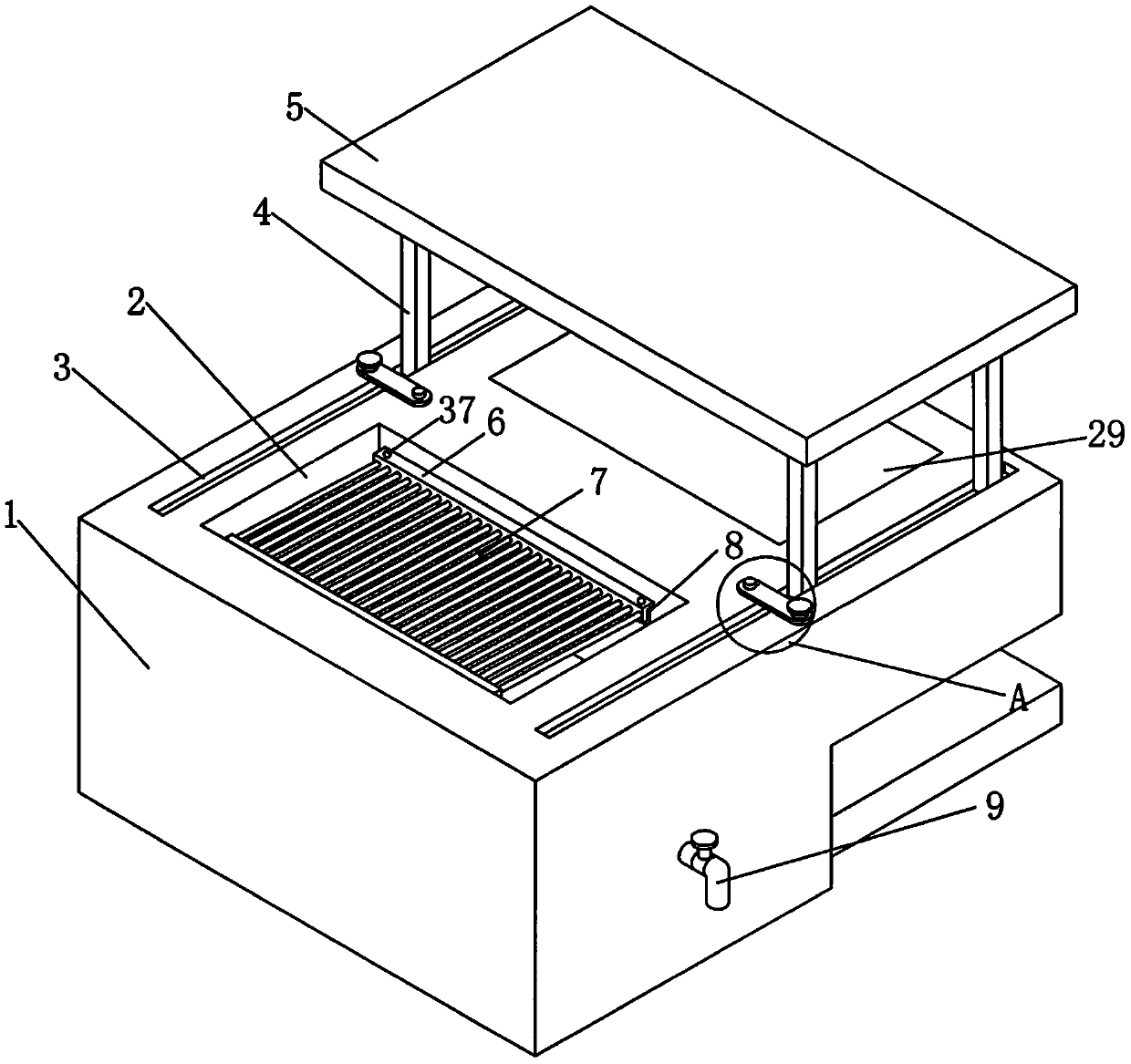

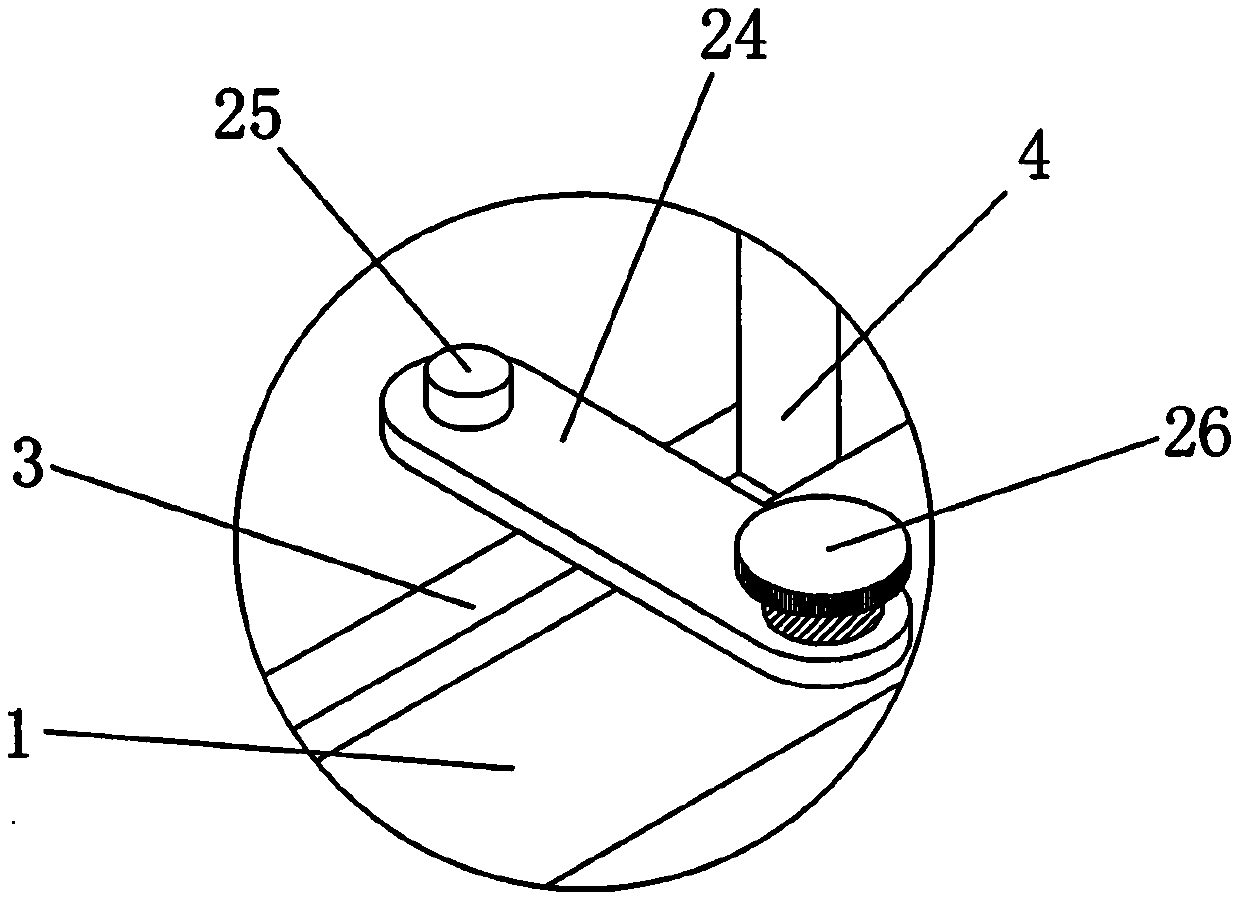

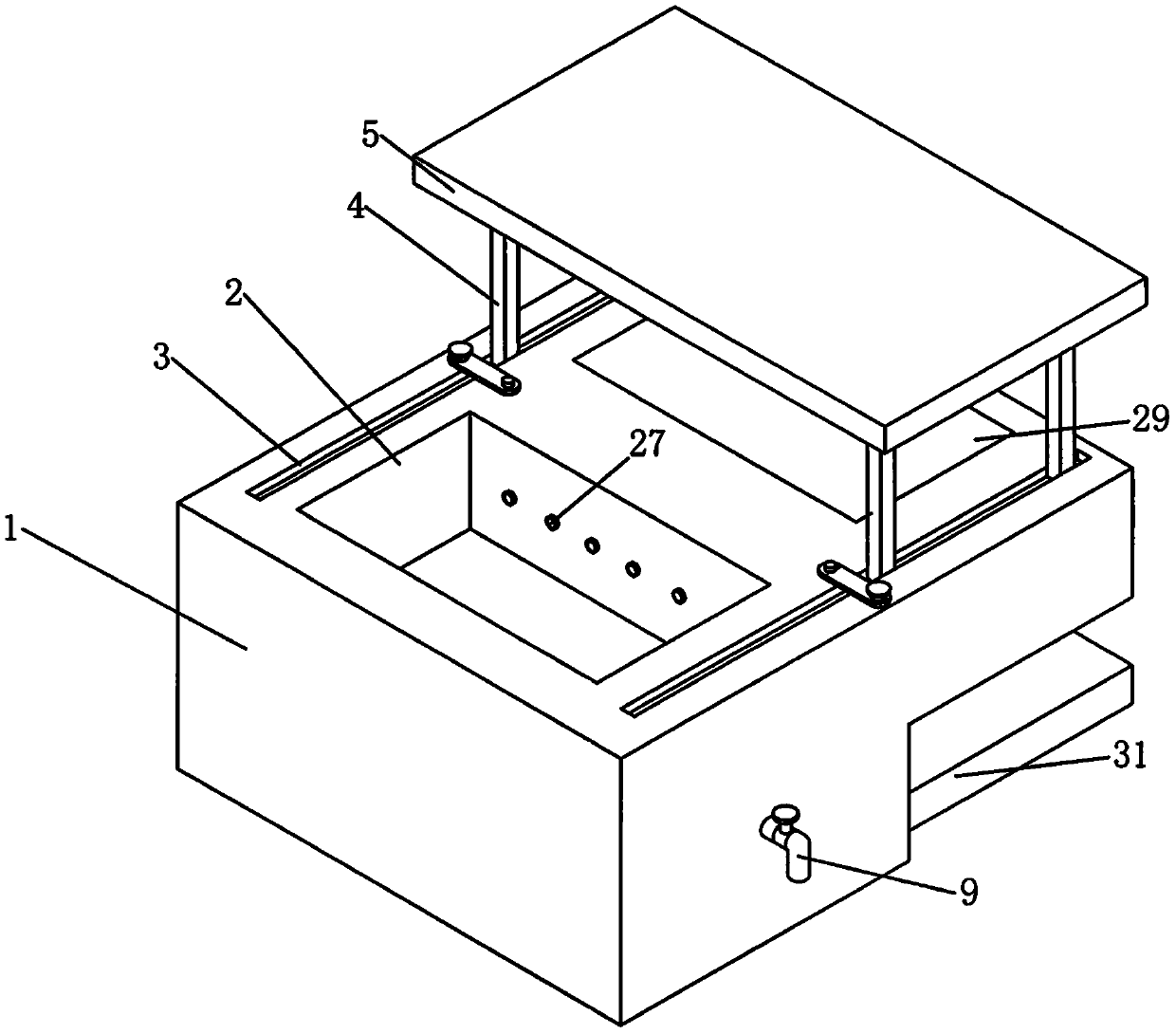

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same components. In order to keep the drawings concise, each drawing only schematically shows the parts related to the invention, and they do not represent the actual structure of the product.

[0023] Such as Figure 1-7 As shown, the present invention is a battery cleaning device, comprising a workbench 1, the top front end of the workbench 1 is provided with a cleaning tank 2 for battery cleaning, the two sides of the cleaning tank 2 are respectively provided with chute 3, and the chute 3 is equipped with a movable brushing unit, the top and rear end of the workbench 1 is provided with a battery drying unit connected to the inside of the cleaning tank 2, and the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com