GaN laser bar cleavage method

A laser, gallium nitride technology, applied in the laser, the structural details of semiconductor lasers, semiconductor lasers, etc., can solve the problems of poor diamond cutting accuracy, low cleavage success rate, harmful cracks, etc., and achieve strong dissociation. Directionality, avoid die quality, improve success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means and functions adopted by the present invention to achieve the predetermined invention objectives, the specific implementation manners of the present invention will be described below in conjunction with the drawings. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Specific steps are as follows:

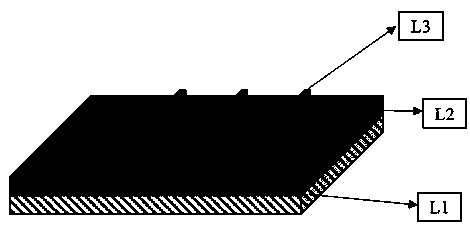

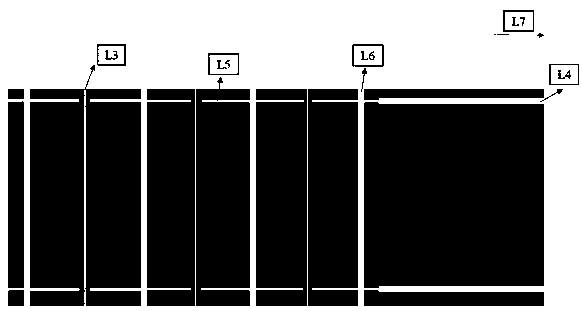

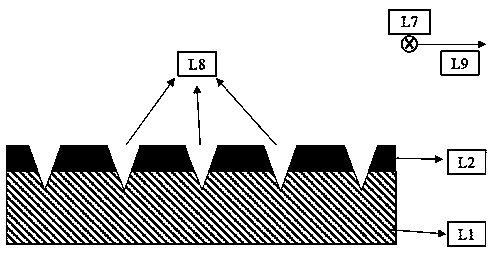

[0024] Step P1: On the GaN epitaxial wafer, use soft mask or hard mask, and use photolithography, dry and wet etching and other methods to etch the ridge structure, such as figure 1 Shown (P electrode, SiO 2 The insulating layer is omitted), and then use PECVD to deposit SiO with a thickness of more than 600 nm on the surface of the sample 2 Insulation layer, gas flow for PECVD: SiH 4 / N 2 O / N 2 =4 / 710 / 180sccm, power 20W, gas pressure 2000mT, but the p-electrode on the ridge surface needs to be exposed through photolithography and RIE pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com