A charging method for lithium ion battery

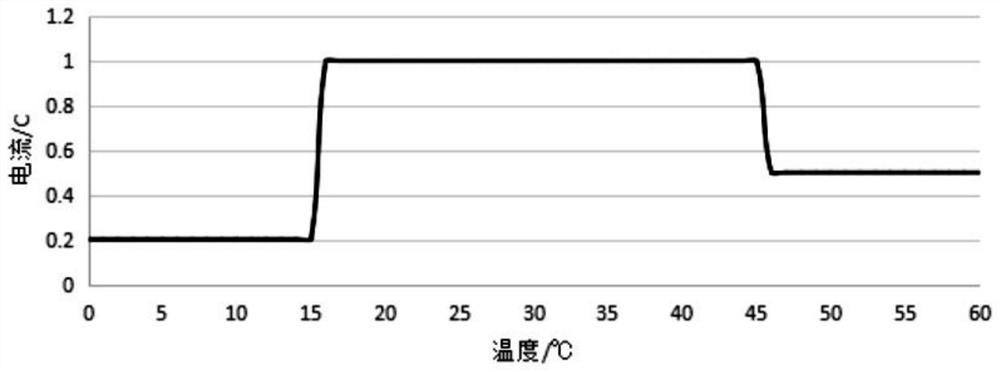

A lithium-ion battery and charging method technology, which is applied in the field of lithium-ion battery charging, can solve the problems of low charging efficiency, quantitative control of the charging process, and long charging time, so as to achieve improved service life, low use cost, and set simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

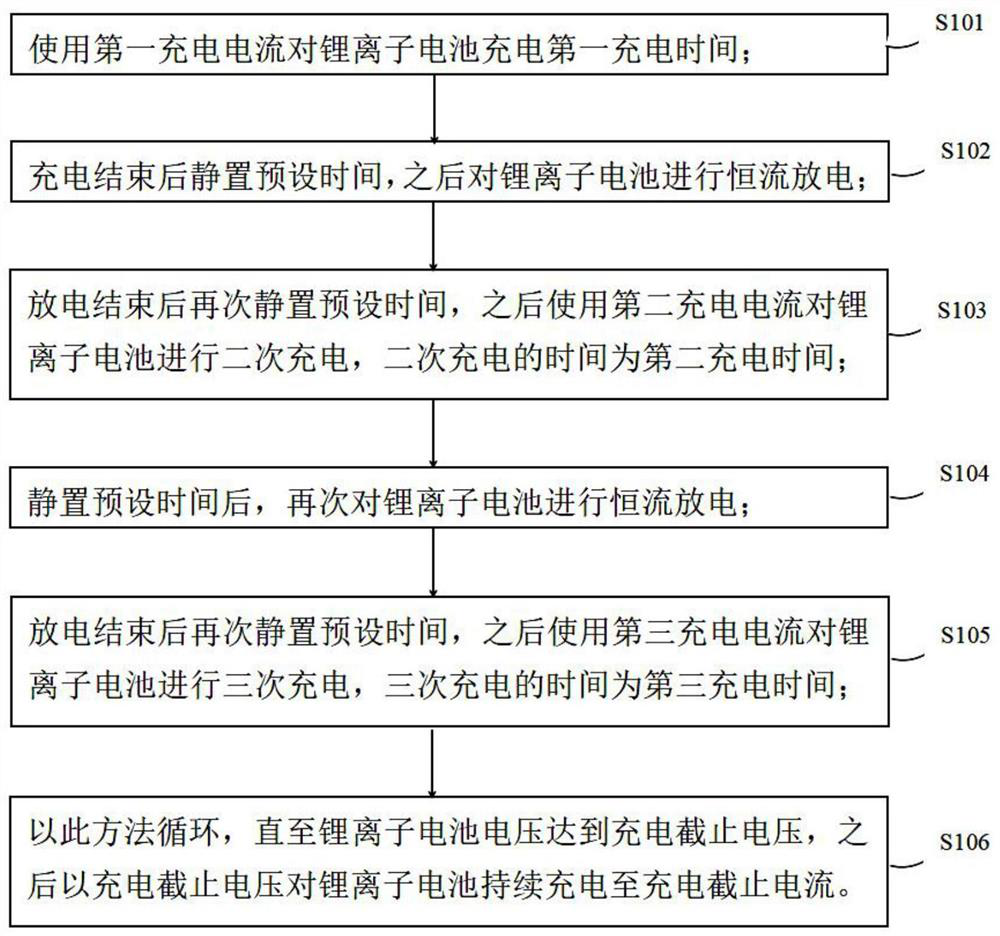

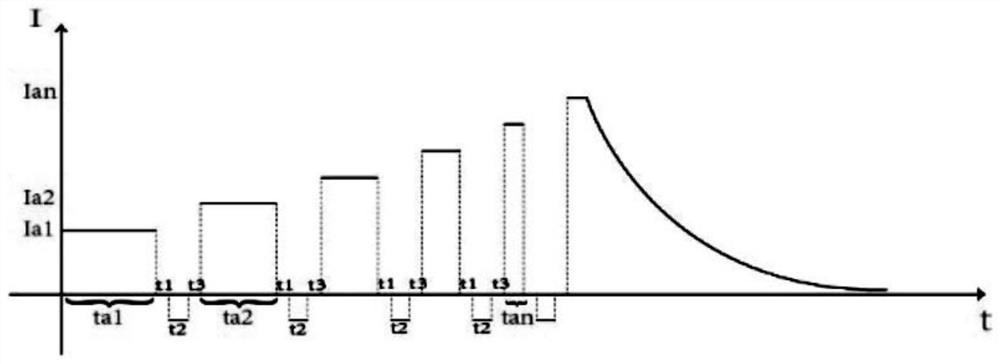

[0090] 1) Set the charging current as 0.08C, 0.1C, 0.12C, 0.14C, 0.16C, 0.18C, 0.2C, 0.22C, 0.24C, 0.26C, and the charging time as 10min, 9min, 8min, 7min, 6min, 5min, 4min, 3min, 2min, 1min; set the charging cut-off voltage to 4.2V, the charging cut-off current to 0.01C, place the battery in an environment of 0°C, and charge and discharge the battery;

[0091] 2) Charge with a current of 0.08C for 10min, then rest for 5s, then discharge with a current of 0.02C for 10s, and then rest for 5s;

[0092] 3) Charge with a current of 0.1C for 9min, then rest for 5s, then discharge with a current of 0.02C for 10s, and then rest for 5s;

[0093] 4) Charge with a current of 0.12C for 8min, then rest for 5s, then discharge with a current of 0.02C for 10s, and then rest for 5s;

[0094] 5) Charge with a current of 0.14C for 7min, then rest for 5s, then discharge with a current of 0.02C for 10s, and then rest for 5s;

[0095] 6) Charge with a current of 0.16C for 6min, then rest for 5s,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com