Polarization maintaining optical fiber end surface axis alignment device and method

A polarization-maintaining fiber, fiber end face technology, applied in polarization fiber, cladding fiber, optics, etc., can solve the problems of inconspicuous imaging features, difficulty, limited work efficiency and application scope, etc., to achieve easy implementation, cost reduction, Guaranteed effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

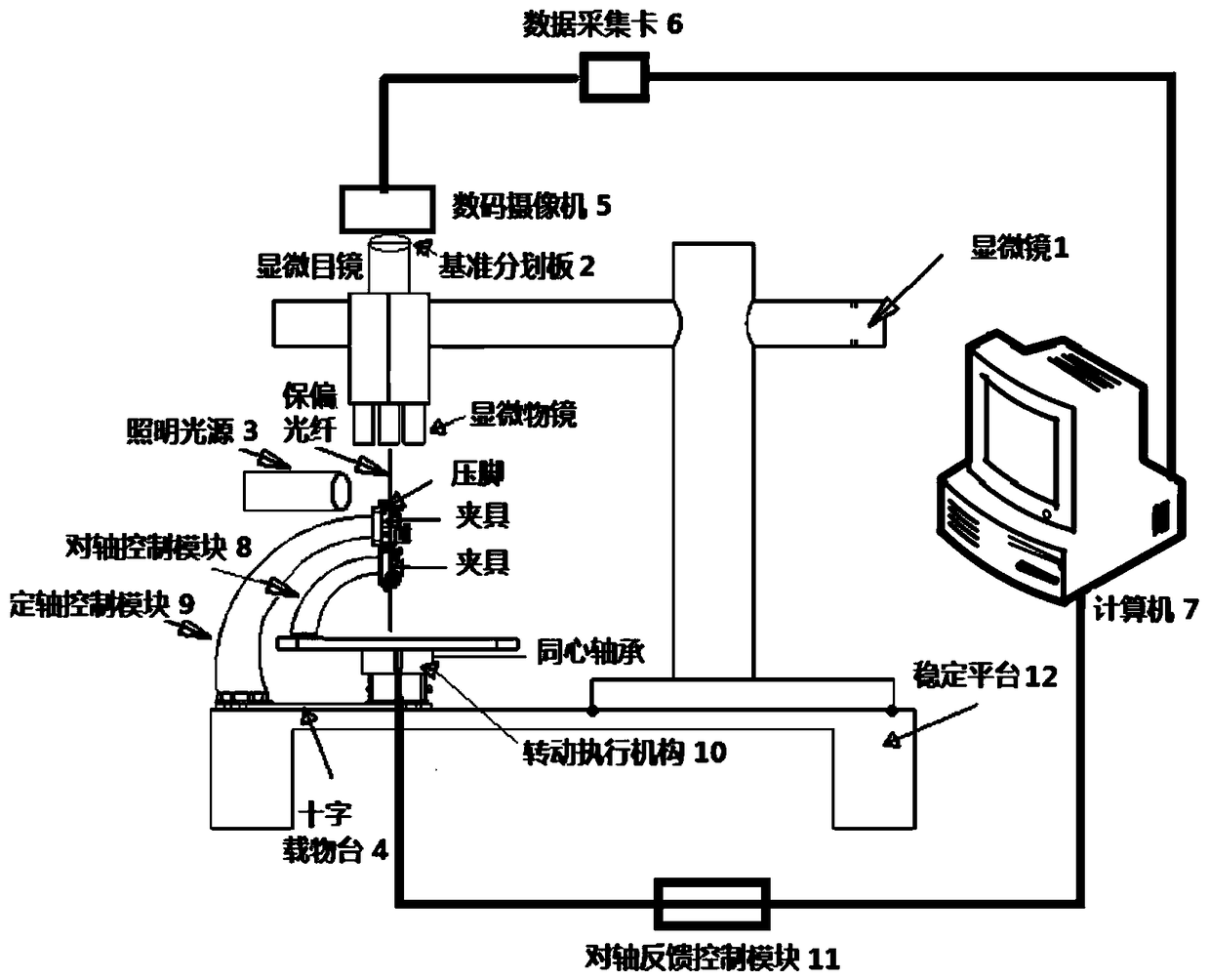

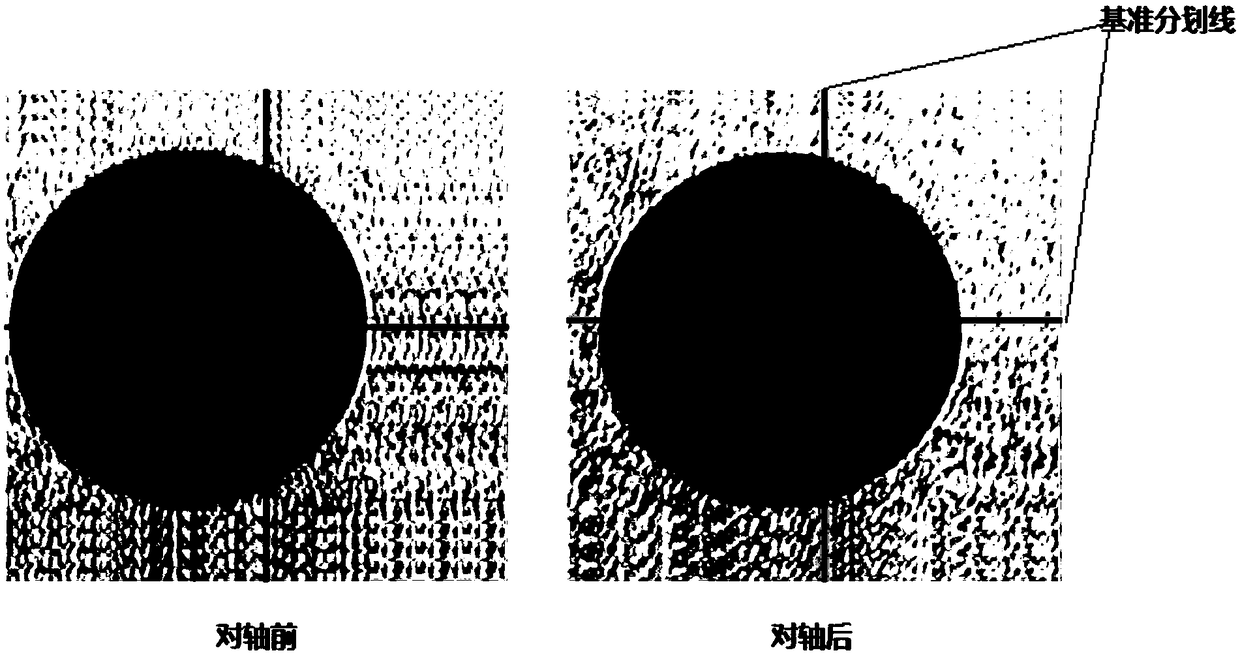

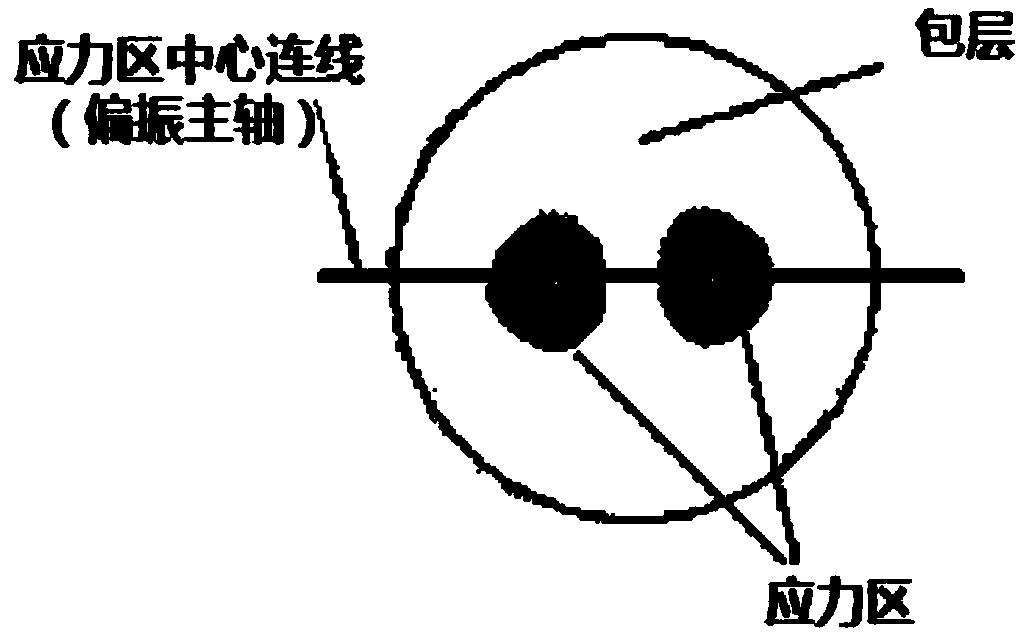

[0046] Such as figure 1 As shown, the present invention provides an end-to-axis device for polarization-maintaining optical fibers. The end-to-axis device includes a microscope 1, an illumination light source 3, a cross stage 4, an axis control module 8, and an axis control module 9 and an actuator 10 for precise rotation of the polarization-maintaining optical fiber; where a reference line is provided in the field of view of the microscope eyepiece, the polarization-maintaining optical fiber a is cut at the end face, and the cutting angle is not greater than 1.5°, and the polarization-maintaining optical fiber after the end face cutting is processed by Clamp the clamp of the axis control module 8, place the end face of the polarization-maintaining fiber to be aligned under the microscope objective; the illumination source 3 is used to illumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com