Permanent magnet type magneto-rheological elastomer vibration isolator

A magneto-rheological elastomer and vibration isolator technology, which is applied in the direction of shock absorbers, springs/shock absorbers, springs, etc., can solve the problems of lack of vibration isolation and reduced vibration isolation effect of vibration isolators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

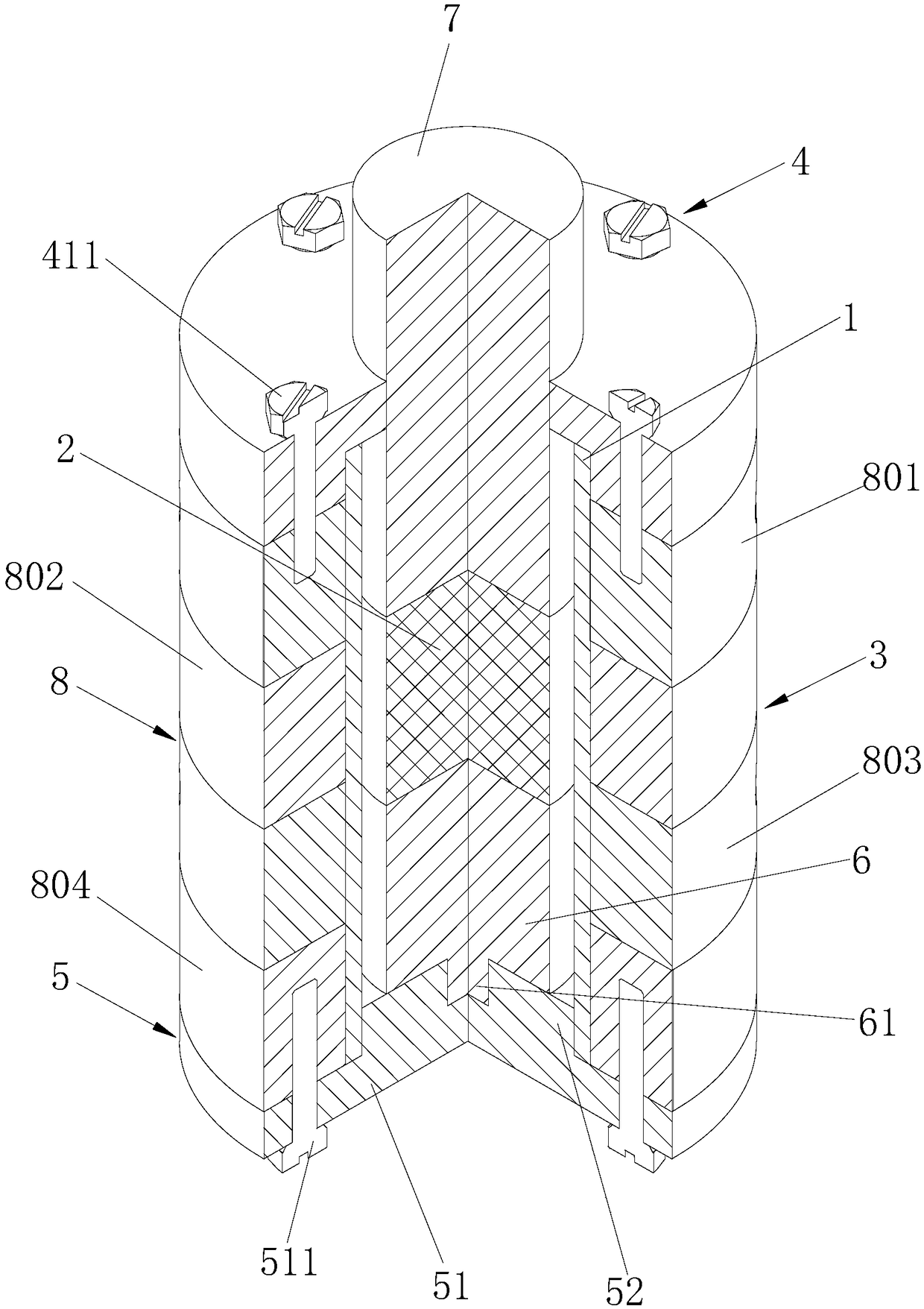

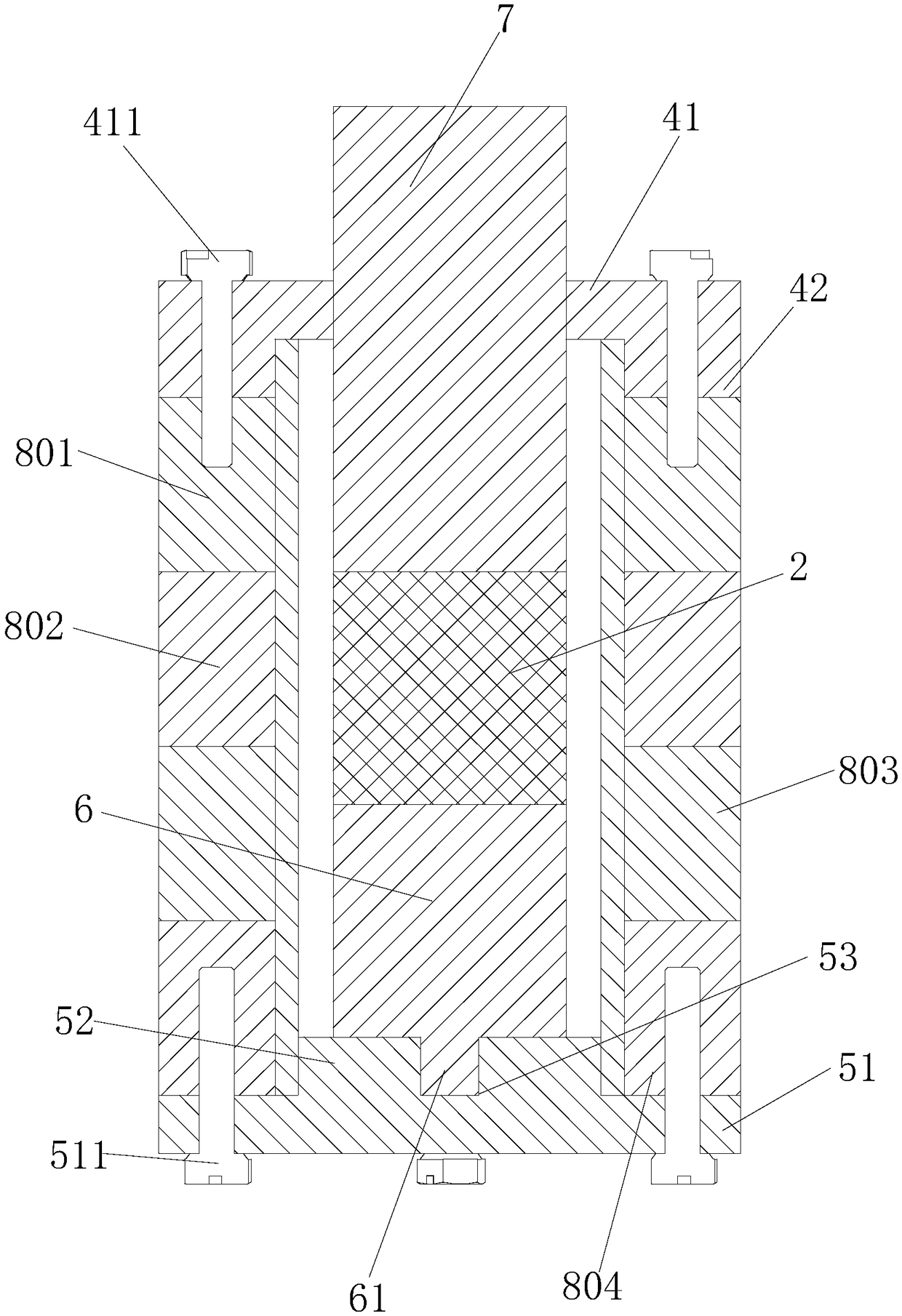

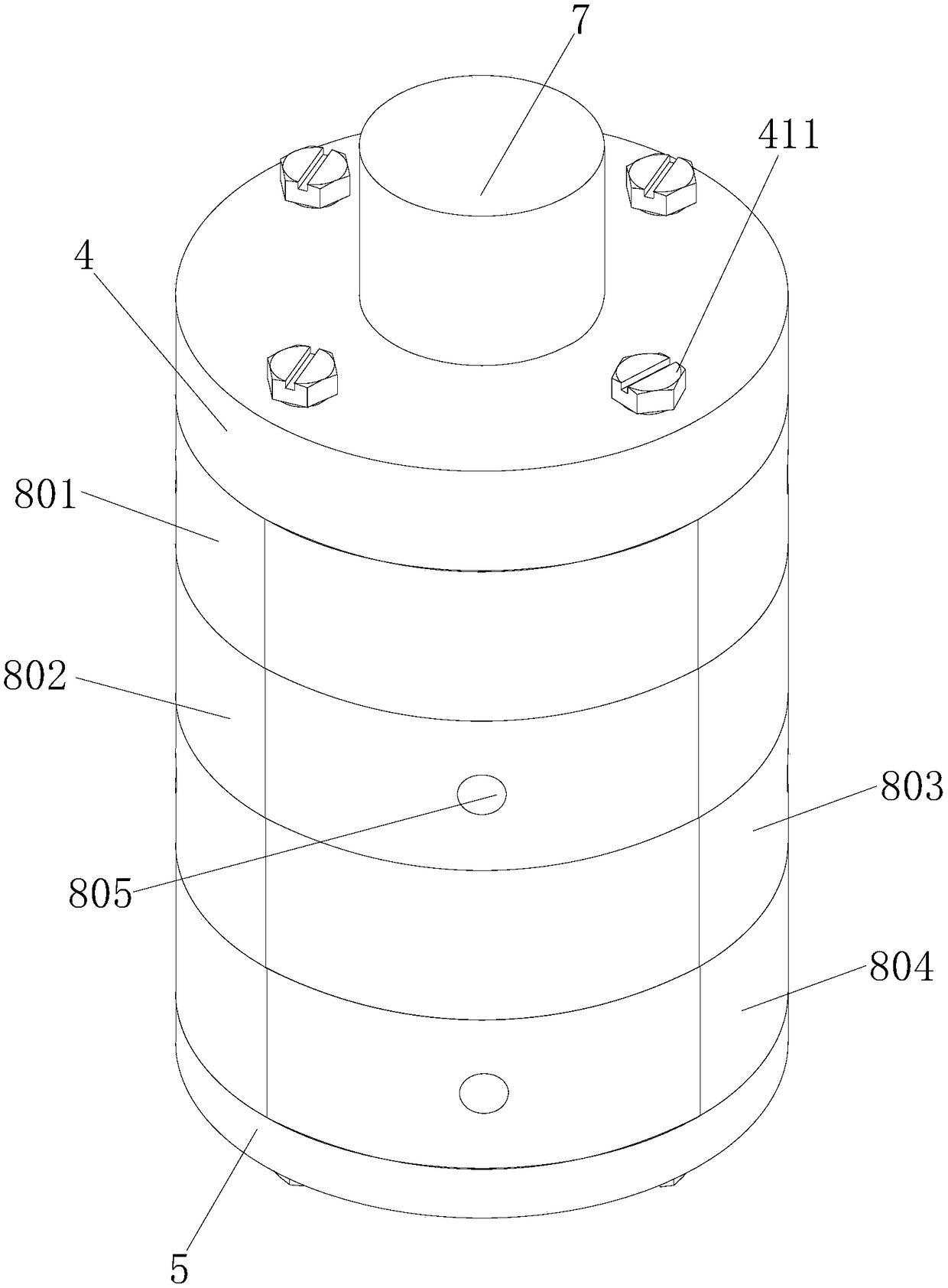

[0035] Embodiment 1, the respective permanent magnet blocks in the first magnetic ring 801, the second magnetic ring 802, the third magnetic ring 803 and the fourth magnetic ring 804 are located in the same vertical plane, and the first magnetic ring 801, the second magnetic ring When the magnetic spacers in the ring 802, the third magnetic ring 803 and the fourth magnetic ring 804 are located in the same vertical plane, the four permanent magnet blocks in the same vertical plane can produce the strongest magnetic induction intensity, that is, the maximum of magnetic flux. Since the magnetic isolation cylinder 1 is a magnetic isolation material, according to the magnetic induction direction of the magnet itself (as shown in the attached manual Figure 5 As shown by the dotted line in the middle), the magnetic flux generated by the four permanent magnet blocks in the same vertical plane will pass through the magnetorheological elastomer 2. At this time, the magnetic flux densi...

Embodiment 2

[0036]Example 2, rotate the second magnetic ring 802 or the third magnetic ring 803, when the second magnetic ring 802 or the third magnetic ring 803 is dislocated, the magnetic flux density at the magnetorheological elastomer 2 will decrease accordingly , the degree of reduction depends on the dislocation area of the permanent magnet blocks in the first magnetic ring 801 , the second magnetic ring 802 , the third magnetic ring 803 and the fourth magnetic ring 804 . When the dislocation area is larger, the magnetic flux passing through the permanent magnet block will be smaller, and the corresponding magnetic flux in the magnetorheological elastomer 2 will be smaller, and then the yield force of the magnetorheological elastomer 2 in the magnetic field will be The smaller will be, the smaller the anti-vibration damping force of the magnetorheological elastomer 2 will be.

[0037] The magneto-rheological elastomer 2 in the present invention conducts magnetism through the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com