Oil felt base cloth and production method thereof

A technology of linoleum base fabric and production method, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc., which can solve the problems of easy deformation and high thermal shrinkage rate of non-woven fabrics, so as to achieve no shrinkage in transverse width and prolong anti-aging time , the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

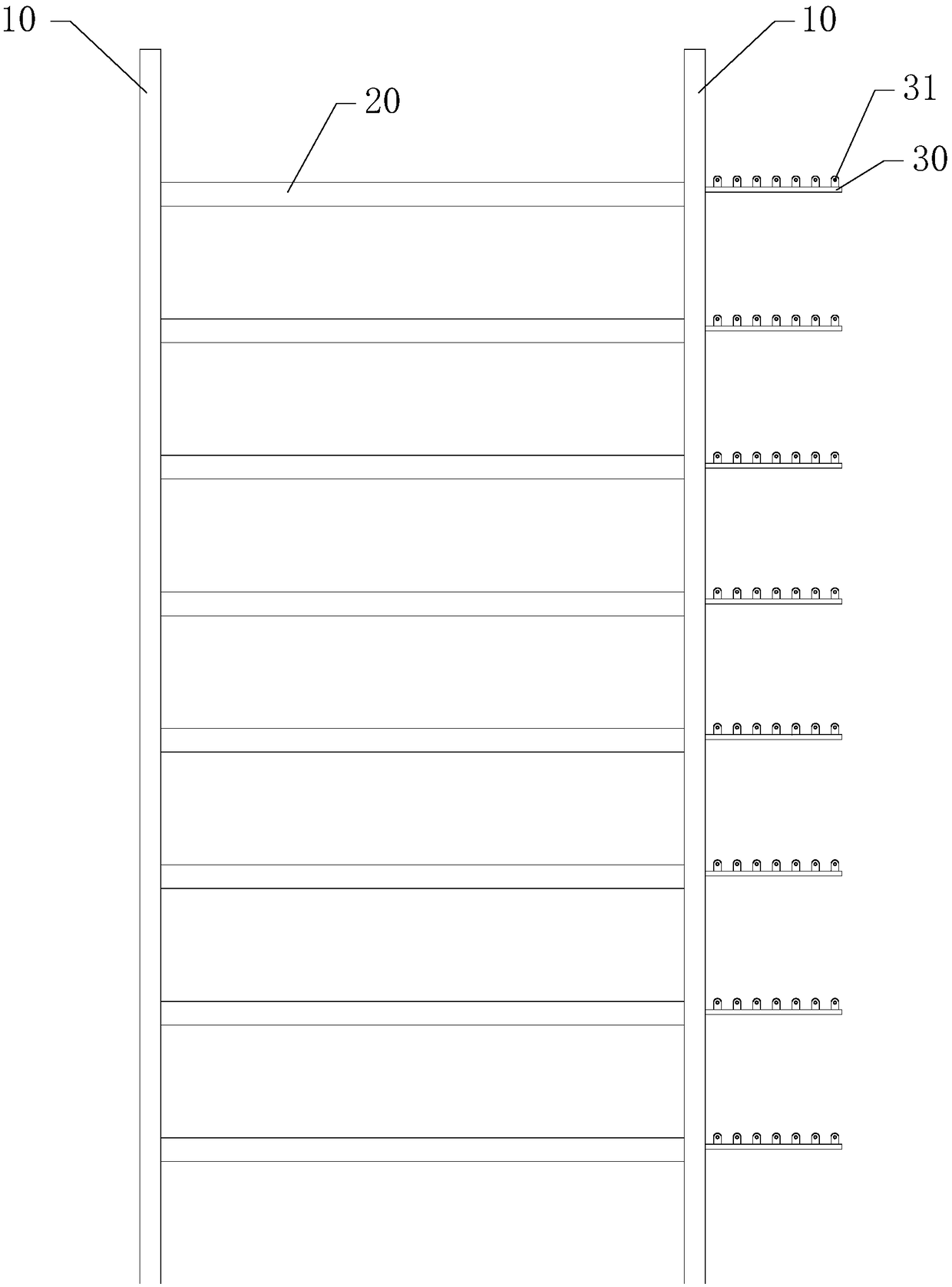

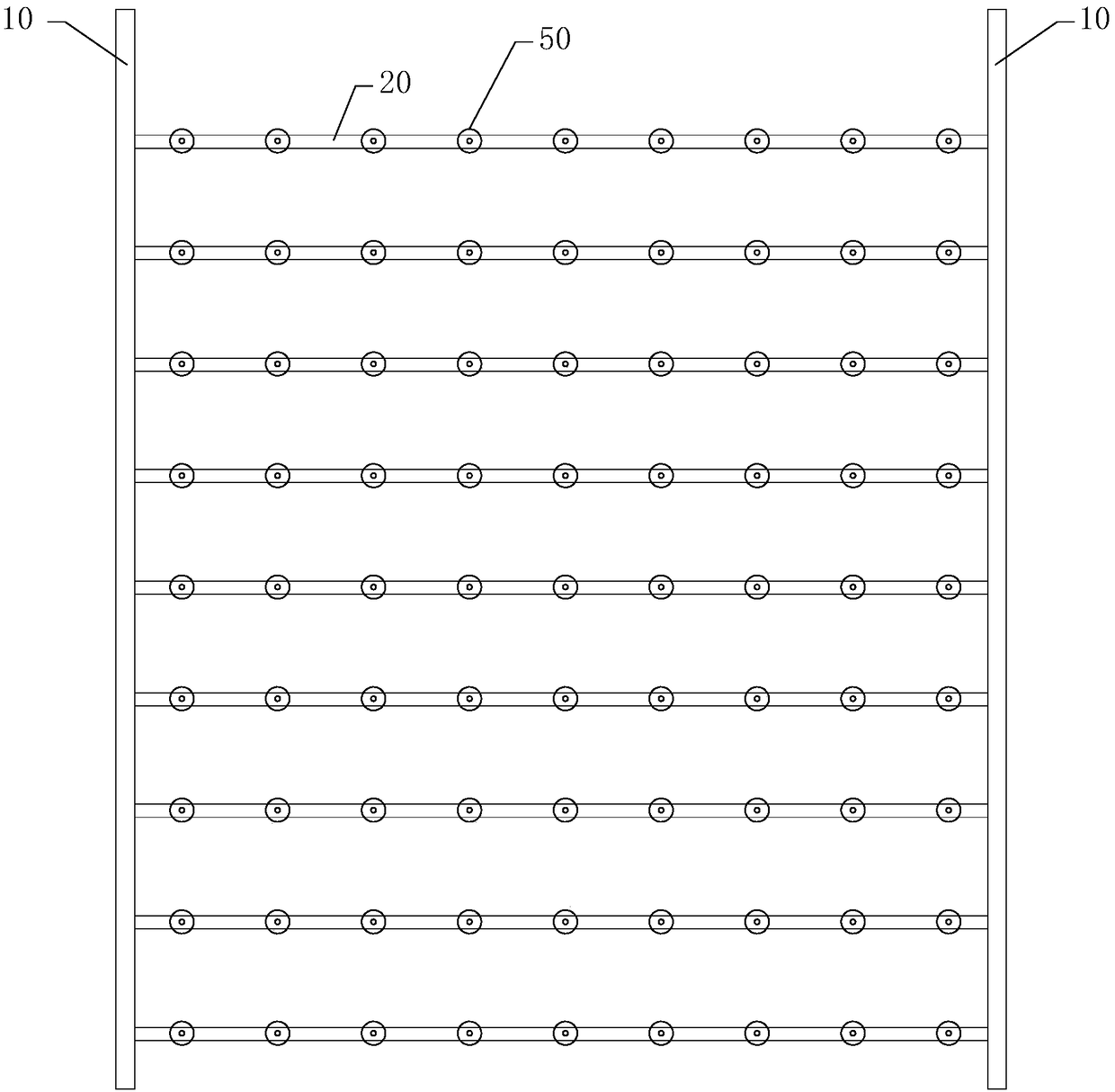

[0043] a linoleum base cloth,

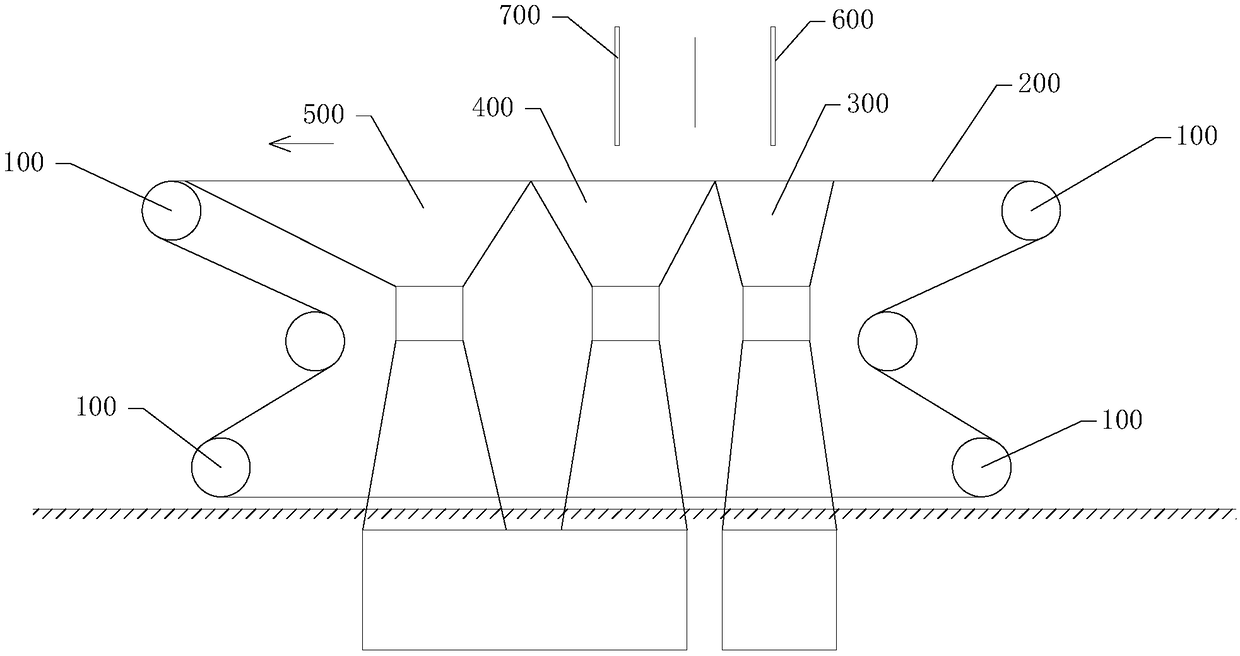

[0044] After crystallization and drying, the polyester chips are input into the screw extruder, and then enter the A and B spinning boxes respectively through the filter and the metering pump. The melt quantitatively passes through the spinneret to form primary fibers. And swing the yarn, lay evenly on the netting curtain to form two layers of fiber webs A and B, and at the same time, the uniform dividing machine adds glass fibers with an interval of 8mm between the two layers of fiber webs A and B, and the fiber nets are sucked firmly by suction. After pre-acupuncture and combination, the glass fiber is straightened by the pre-extrusion cloth, reinforced by main acupuncture, dipped in glue, dried and rolled to obtain the finished linoleum base cloth.

[0045] The pre-acupuncture and the main acupuncture process adopt long-filament acupuncture, and the needle planting density is 4000 pieces / m2, the acupuncture frequency is 1500 times / min, and th...

Embodiment 2

[0049]After crystallization and drying, the polyester chips are input into the screw extruder, and then enter the A and B spinning boxes respectively through the filter and the metering pump. The melt quantitatively passes through the spinneret to form primary fibers. And swing the yarn, lay evenly on the netting curtain to form two layers of fiber webs A and B, and at the same time, the uniform splitter adds glass fibers with an interval of 6mm between the two layers of fiber webs A and B, and the fiber webs are sucked firmly by suction. After pre-acupuncture and combination, the glass fiber is straightened by the pre-extrusion cloth, reinforced by main acupuncture, dipped in glue, dried and rolled to obtain the finished linoleum base cloth.

[0050] The pre-acupuncture and the main acupuncture process adopt long-filament acupuncture, and the needle planting density is 3500 pieces / m2, the acupuncture frequency is 1400 times / min, the acupuncture depth is 6mm, and the starch adh...

Embodiment 3

[0054] After crystallization and drying, the polyester chips are input into the screw extruder, and then enter the A and B spinning boxes respectively through the filter and the metering pump. The melt quantitatively passes through the spinneret to form primary fibers. And swing the yarn, lay evenly on the netting curtain to form two layers of fiber webs A and B, and at the same time, the uniform splitter adds glass fibers with an interval of 10mm between the two layers of fiber webs A and B, and the fiber webs are sucked firmly by suction. After pre-acupuncture and combination, the glass fiber is straightened by the pre-extrusion cloth, reinforced by main acupuncture, dipped in glue, dried and rolled to obtain the finished linoleum base cloth.

[0055] The pre-acupuncture and the main acupuncture process adopt long-filament acupuncture, and the needle planting density is 4500 pieces / m2, the acupuncture frequency is 1600 times / min, and the acupuncture depth is 10mm. The concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com