Disposal method and device for waste electronic products

An electronic product and processing method technology, applied in the field of waste electronic product processing and its processing device, can solve the problems of restricting the practicability of electronic product waste, not complying with environmental protection, inability to comply with the environmental protection, etc., to avoid gas explosion problems, reduce costs, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

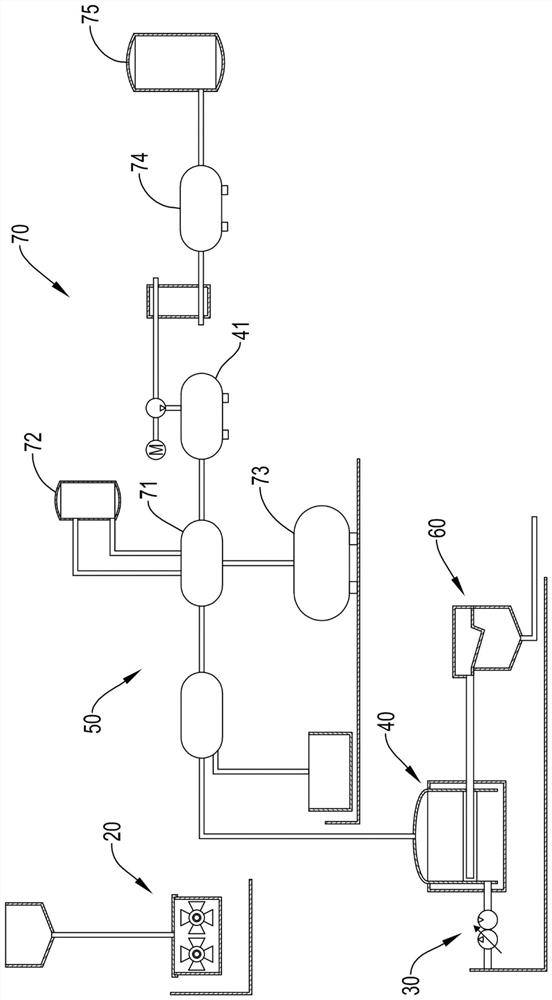

[0055]The present invention provides a method and device for processing waste electronic products. Please refer tofigure 1 andfigure 2 As shown in the flow block diagram, the waste electronic product processing method includes a preparation step, a vacuum cracking step, a recovery step, a separation step, and a subsequent processing step. The details of each operation step are as follows.

[0056]A. Preparation steps: please refer tofigure 2 As shown, a plurality of waste electronic products 10 to be processed, a crusher 20, a power supply device 30, a vacuum cracking device 40, a filter device 50, an electrolysis device 60, and a separation device 70 are prepared. Preferably, The plurality of discarded electronic products 10 to be processed may be discarded electronic circuit boards, printed circuit boards, or transmission lines, etc. The power supply device 30 and the crusher 20, the vacuum cracking device 40, the filtering device 50, and the electrolysis device 60 and the separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com