Particle-reinforced reprocessable rubber material and preparation method thereof

A technology of repeated processing and particle reinforcement, applied in the field of rubber recycling, can solve the problems of low mechanical properties of polymer materials, complex synthesis process, difficult to widely use, etc., to achieve repeatable processing and recycling, simple process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0026] (1) adding epoxidized natural rubber, white carbon black, and aluminum chloride to an internal mixer and kneading for 10 minutes in sequence, and the kneading temperature is 80° C. to obtain a kneaded rubber;

[0027] (2) Vulcanize the obtained mixed rubber at 180° C. according to the positive vulcanization time;

[0028] (3) Crushing the vulcanized rubber into 80-mesh rubber powder, and hot pressing at 180°C for 20 minutes to obtain reprocessed rubber.

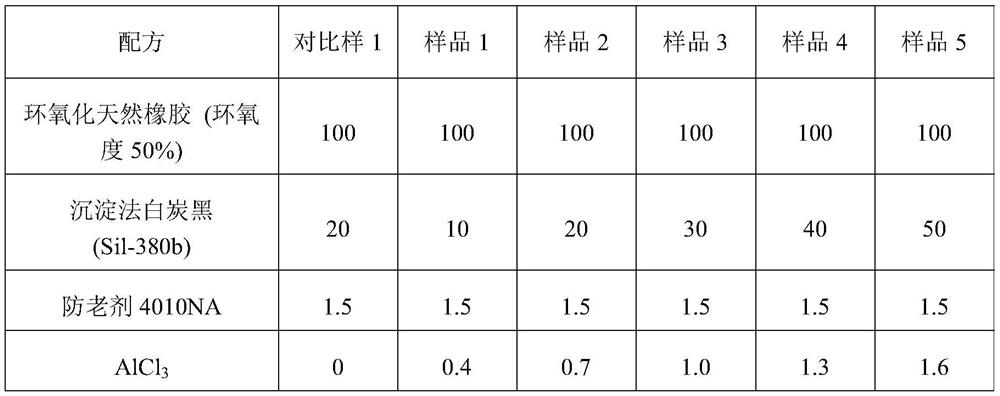

[0029] By changing the amount of white carbon black and aluminum chloride added, comparative samples and 5 examples were prepared according to the above-mentioned method of the present invention. The specific formulations of the comparison sample and the embodiment are shown in the following table 1, and the unit of each material consumption in the table is g.

[0030] Table 1

[0031]

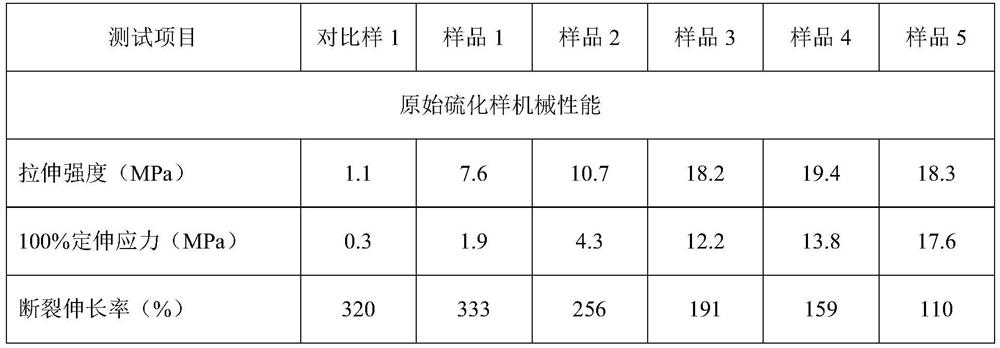

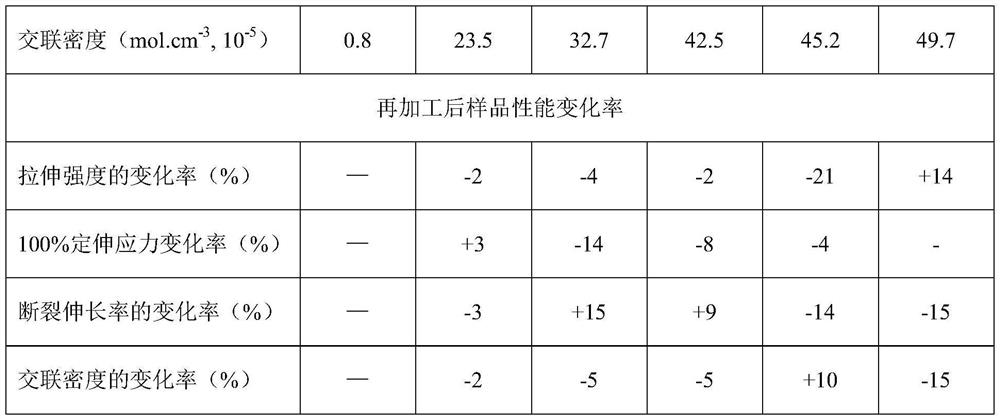

[0032] According to the Chinese national standard GB / T 528-2009, the properties of all formulations in Example 1 were comprehens...

Embodiment example 2

[0037] (1) Epoxidized styrene-butadiene rubber, montmorillonite, and zinc chloride were successively added to an internal mixer and mixed for 10 minutes at a mixing temperature of 50° C. to obtain a mixed rubber;

[0038] (2) vulcanize the obtained mixed rubber at 150° C. according to the positive vulcanization time;

[0039] (3) Crushing the vulcanized rubber into 80-mesh rubber powder, and hot pressing at 150°C for 60 minutes to obtain reprocessed rubber.

[0040] By changing the amount of montmorillonite and aluminum chloride added, comparative samples and 4 examples were prepared according to the above-mentioned method of the present invention. Contrast sample and embodiment specific formula are shown in the following table 3, and the consumption unit of each material in the table is g.

[0041] table 3

[0042]

[0043]The properties were tested according to the Chinese national standard GB / T 528-2009. The typical properties of vulcanized rubber samples and the chang...

Embodiment example 3

[0047] (1) Epoxidized butadiene rubber, kaolin, and ferric chloride were successively added to an internal mixer and mixed for 10 minutes at a mixing temperature of 30° C. to obtain a mixed rubber;

[0048] (2) vulcanize the obtained mixed rubber at 160°C according to the positive vulcanization time;

[0049] (3) Crushing the vulcanized rubber into 80-mesh rubber powder, and hot pressing at 160°C for 30 minutes to obtain reprocessed rubber.

[0050] Changing the added amount of kaolin and aluminum chloride prepared comparative samples and 4 examples according to the above-mentioned method of the present invention. The specific formulations of the comparison sample and the embodiment are shown in the following table 5, and the unit of each material consumption in the table is g.

[0051] table 5

[0052]

[0053] The properties were tested according to the Chinese national standard GB / T 528-2009. The typical properties of vulcanized rubber samples and the changes in proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com