Low-frequency vibrating compacted shrinkage-compensating concrete and preparation method thereof

A technology for compensating shrinkage and concrete, applied in the field of concrete, can solve the problems of insufficient hydration moisture of cement particles, no increase in strength, fast expansion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

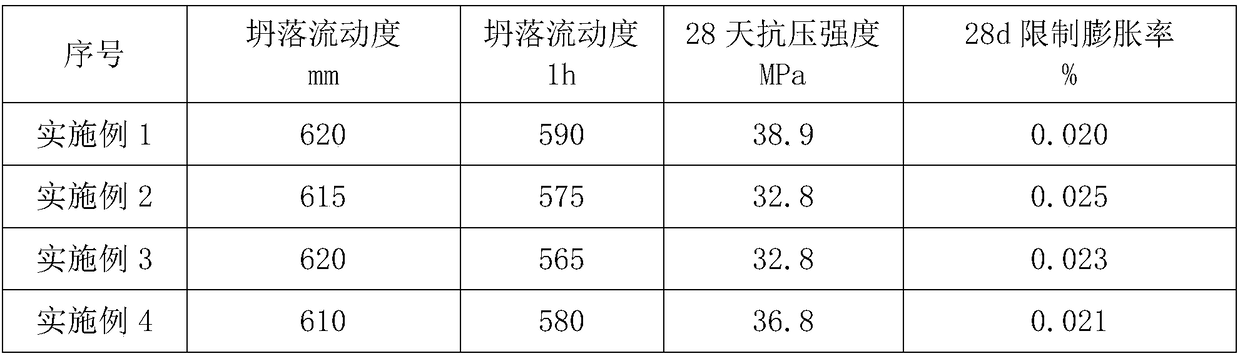

Examples

preparation example Construction

[0028] The present invention also relates to a preparation method of low-frequency vibrating compacted and shrinkage-compensated concrete, comprising the following steps:

[0029] (1) Add sand material, stone material, cementitious material and expansion agent to the mixer in sequence according to the above dosage;

[0030] (2) Prepare the water reducer and water into a solution according to the above dosage, add the water reducer solution to the mixer at a uniform speed, and stir evenly;

[0031] (3) Pour evenly mixed concrete into the formwork, and vibrate at low frequency for 2 minutes (horizontal or vertical).

[0032] In order to improve the vibrating and compacting performance of concrete, a viscosity modifier is introduced, so that the concrete can obtain a lower dynamic viscosity under the condition of low slump, and it is easy to pave and compact during the vibrating process; in order to reduce the concrete after hardening Porosity, introduce a certain amount of defo...

Embodiment 1

[0034] The preparation method of the low-frequency vibration compacting and shrinkage-compensating concrete of the present embodiment comprises the following steps:

[0035] (1) Sand material: 970kg, stone material: 950kg, cementitious material (cement: 300kg, active admixture (fly ash: 30kg; zeolite powder: 30kg)), expansion agent (admixture and calcium sulfoaluminate expansion agent The percentage by weight is 1:1.5%, wherein, calcium sulfoaluminate expansion agent: 31kg, NaAlO2: 0.31kg, KAlO2: 0.155kg), sand material, stone material, cementitious material and expansion agent are added to the mixer in turn according to the above consumption;

[0036] (2) Water reducer: 3.6kg, water: 165kg, prepare water reducer and water into a solution according to the above dosage, add water reducer solution to the mixer at a uniform speed, and stir evenly;

[0037] (3) Pour evenly mixed concrete into the formwork and vibrate at low frequency for 2 minutes.

Embodiment 2

[0039] (1) Sand material: 920kg, stone material: 1000kg, cementitious material (cement: 240kg, active admixture (fly ash: 40kg; zeolite powder: 80kg)), expansion agent (admixture and calcium sulfoaluminate expansion agent The weight percentage is 1:1.0%, wherein, calcium sulfoaluminate expansion agent: 28kg, NaAlO2: 0.28kg), sand material, stone material, cementitious material and expansion agent are added into mixer in turn according to the above consumption;

[0040] (2) Water reducer: 3.4kg, water: 170kg, prepare water reducer and water according to the above amount to make a solution, add water reducer solution to the mixer at a uniform speed, and stir evenly;

[0041] (3) Pour evenly mixed concrete into the formwork and vibrate at low frequency for 2 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com