Method for purifying carbon disulfide with dividing wall column

A technology of carbon disulfide and the next-door tower, which is applied in the direction of carbon disulfide and carbon sulfur compounds, can solve the problems of additional energy consumption, residual, high energy consumption, etc., to reduce equipment investment and energy consumption, reduce device energy consumption, and reduce land occupation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Include the following steps:

[0047] (1) Incoming raw materials

[0048] Carbon disulfide synthesizer output including CS 2 47%, S 3%, H 2 S 50% (mass ratio) of carbon disulfide crude product 1 is sent to the dividing wall column at a feed rate of 6250kg / h; the raw material is sent into the feed port E, and the feed port E is opened on the sixth tray of the pre-separation zone A On, feed temperature 30°C, pressure 6bar.

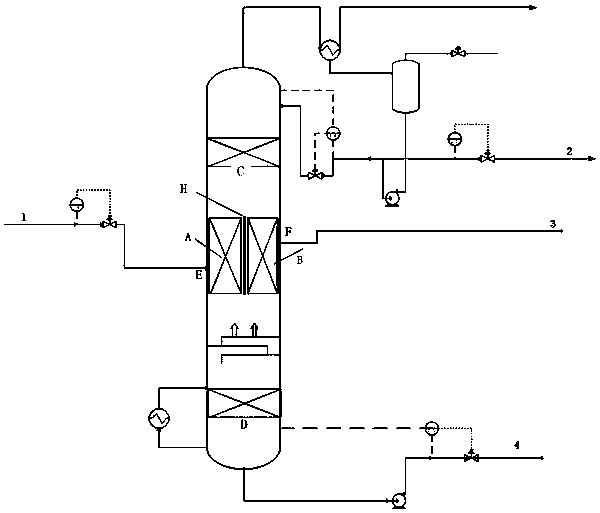

[0049] Described next door tower, main tower has 30 trays, public rectification section C has 10 trays, public stripping section D has 12 trays, tower middle section has 8 trays, dividing plate H divides tower middle section It is divided into pre-separation area A and pure product area B, and the cross-sectional area ratio of pre-separation area A and pure product area B is 0.5:1.

[0050] (2) Separation in the next wall tower

[0051] Steam is fed into the bottom of the tower, the temperature at the bottom of the tower is 100°C, the pressure is...

Embodiment 2

[0053] (1) Incoming raw materials

[0054] Carbon disulfide synthesizer output including CS2 69%, S 1%, H 2 S 30% (mass ratio) carbon disulfide crude product 1 is sent into the dividing wall column at a speed of 6250kg / h; the raw material is sent in from the feed port E, and the feed port E is opened on the 8th tray of the pre-separation zone A, Feed temperature 180°C, pressure 10bar;

[0055] Described next door tower, main tower has 40 trays, public rectification section C has 16 trays, common stripping section D has 12 trays, tower middle section has 12 trays, dividing plate H divides tower middle section It is divided into pre-separation area A and pure product area B, and the cross-sectional area ratio of pre-separation area A and pure product area B is 1.5:1.

[0056] (2) Separation in the next wall tower

[0057] Steam is fed into the bottom of the tower, the temperature at the bottom of the tower is 140°C, the pressure is 10bar, the discharge from the bottom of the ...

Embodiment 3

[0059] (1) Incoming raw materials

[0060] Carbon disulfide synthesizer output including CS 2 58%, S 2%, H 2 The carbon disulfide crude product 1 of S 40% (mass ratio) is sent into the dividing wall column at a speed of 6250kg / h; the raw material is sent into the feed port E, and the feed port E is opened on the fourth tray of the pre-separation zone A, Feed temperature 100°C, pressure 8bar;

[0061] Described next door tower, main tower has 20 trays, public rectification section C has 8 trays, public stripping section D has 6 trays, tower middle section has 6 trays, dividing plate H divides tower middle section It is divided into pre-separation area A and pure product area B, and the cross-sectional area ratio of pre-separation area A and pure product area B is 2:1.

[0062] (2) Separation in the next wall tower

[0063] Steam is fed into the bottom of the tower, the temperature at the bottom of the tower is 120°C, the pressure is 8bar, the discharge from the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com