Multi-material storage container

A storage container and multi-material technology, which is applied in the fields of light industry, chemical industry, food, and medicine, can solve the problems of the normal production and operation of the device, the low utilization rate of the device space, and the large area occupied by the equipment layout, so as to achieve flexible design, Small footprint and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

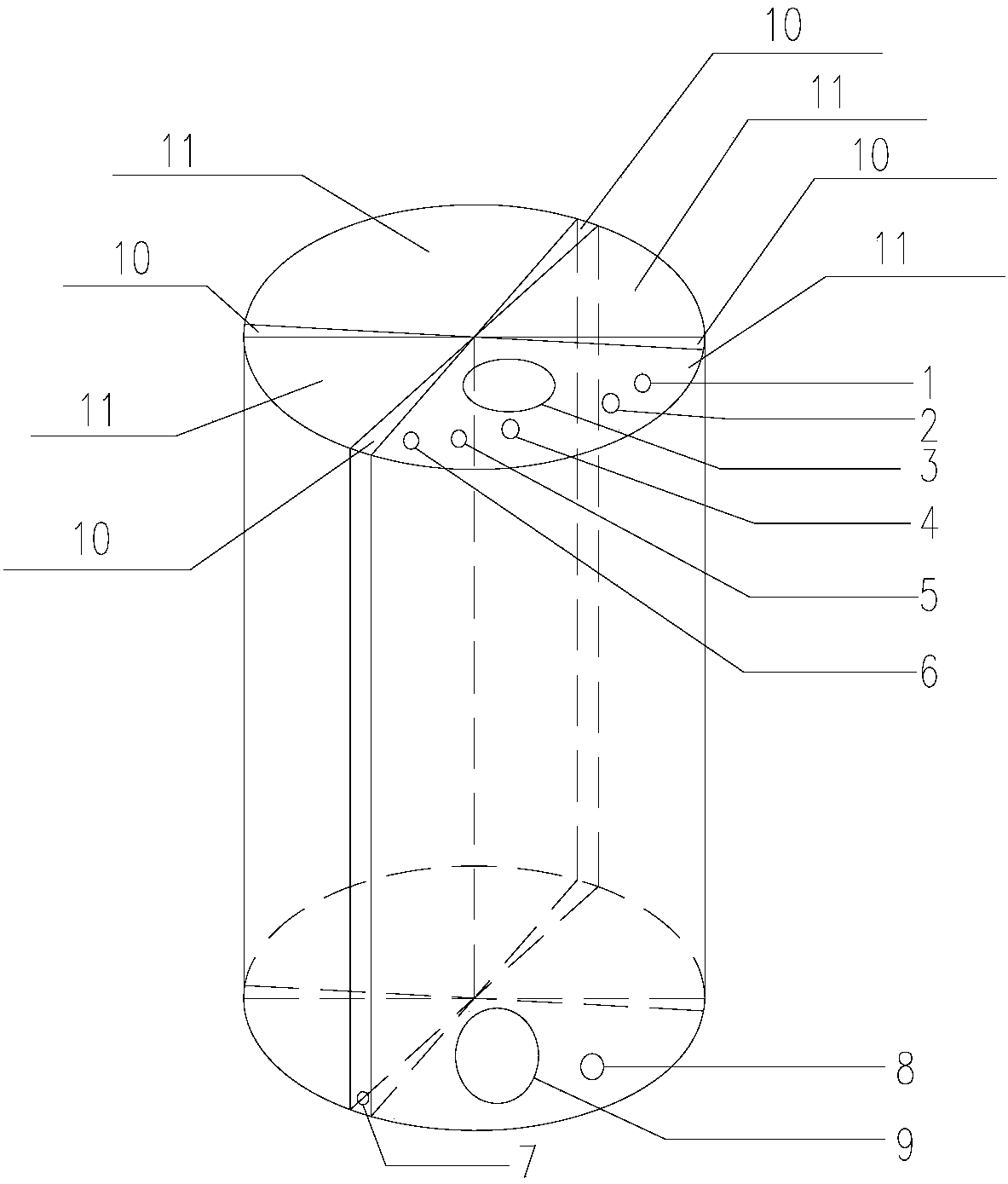

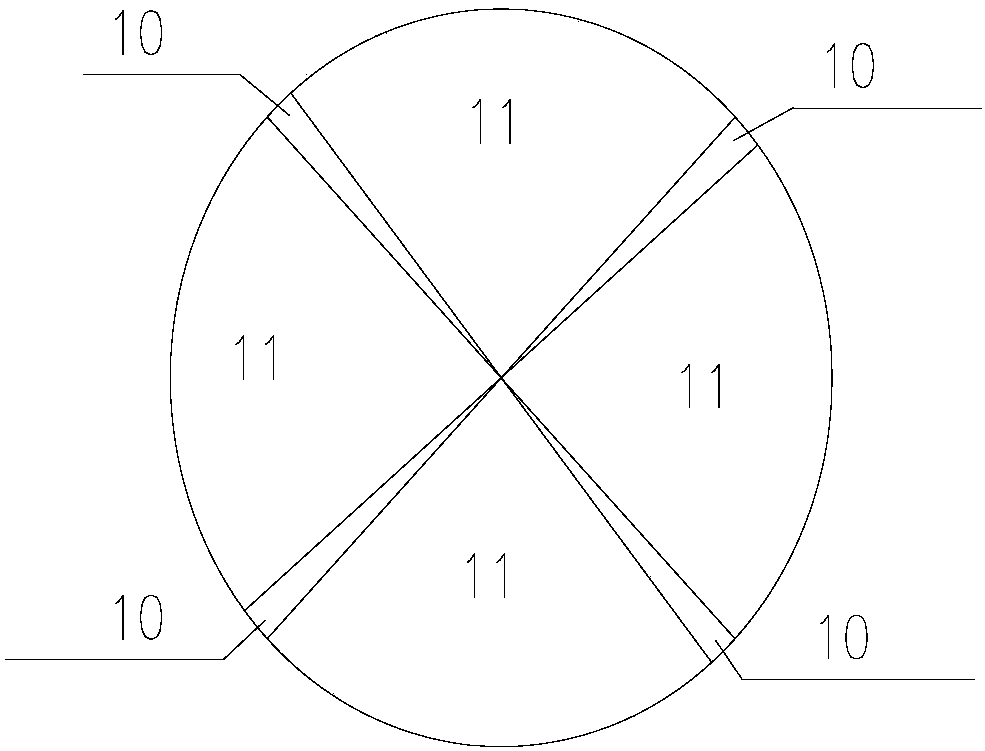

[0026] A multi-material storage container, the structure of which is as follows figure 1 As shown, it includes a storage tank and is arranged in the storage tank, and the internal space of the storage tank is divided into a plurality of hollow interlayers 10 that are independent of each other. The hollow interlayer 10 is connected to each other by the inner end, and the outer end is separated from each other. A baffle connected to the inside wall of the tank.

[0027] The baffles constituting the interlayer are flexibly connected, and the distance between the outer ends can be adjusted. In addition, the number of partitions can be adjusted in the storage tank structure design according to the number of storage liquid spaces 11 required; and each liquid storage The volume of the space can be adjusted accordingly by changing the angle and position of the partition. This embodiment takes four liquid storage spaces as an example, which can store 4 kinds of materials respectively,...

Embodiment 2

[0035] Storage of different raw materials in chemical plants

[0036] Storage medium: benzene, toluene, methanol

[0037] Description: A chemical plant renovation project needs to use three materials such as benzene, toluene, and methanol as raw materials for its plant, and the design needs to add three new volumes of 100m each 3 The original design size of the storage tank is φ5000×5500mm. Due to the limitation of the existing installation site, the layout of the three storage tanks cannot be spread out, and the volume of the storage tank can only be reduced; now it is possible to design a volume of 330m 3 storage tank, the size is φ7200×8200mm, and three 100m 3 The liquid storage interlayer greatly reduces the total space occupied by the equipment, and can be arranged in a limited space to meet the needs of the device.

Embodiment 3

[0039] Storage of different fruit juices in the food industry

[0040] Storage medium: apple juice, orange juice, peach juice, watermelon juice, mango juice

[0041] Description: A beverage factory blends five juices with different flavors according to customers' preferences: apple juice, orange juice, peach juice, watermelon juice and mango juice. Five 20m 3 intermediate storage tank. According to the present invention, a φ5500×5200mm about 120m 3 For storage tanks, 5 liquid storage interlayers are separated by partitions, which can meet the demand, greatly reduce the equipment footprint, and the device is more neat and beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com