Continuous lens automatic grinding method

A lens, automatic technology, used in grinding machines, grinding feed motion, grinding workpiece supports, etc., can solve the problems of low production efficiency, poor product quality stability, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

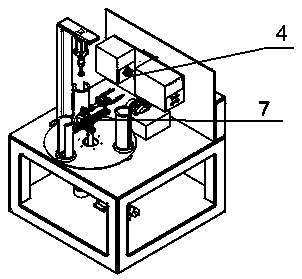

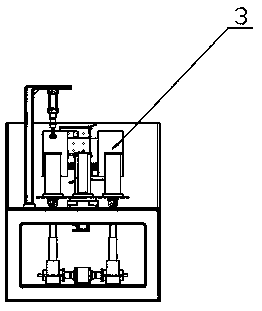

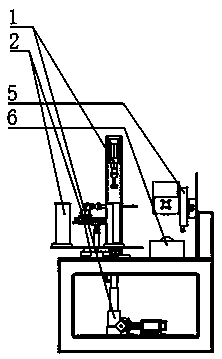

[0045] During specific implementation: if Figure 1 to Figure 12 As shown, a continuous automatic lens polishing method is characterized in that three lens storage spaces are arranged in a circular array with the center of the turntable on the horizontal turntable, and the three lens storage spaces are respectively corresponding to the feeding station, The blanking station and the discharging and receiving station; and complete the placement of the lens blank in the lens storage space corresponding to the discharging and receiving station, and rely on the horizontal rotation of the turntable itself to make the three lens storage spaces compatible with the loading station, The unloading station and the unwinding and receiving station are switched in sequence, and the corresponding lens blank is rotated to the loading station, and then the lens blank is transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com