Die casting shaping device for machining magnesium alloy

A magnesium alloy and casting technology, which is applied in the field of die-casting and molding devices for magnesium alloy processing, can solve problems affecting appearance and quality, filling cold material at the end, high-temperature oxidation, etc., achieve simple and reasonable structure, avoid high-temperature oxidation, and improve product quality. Effects on Quality and Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

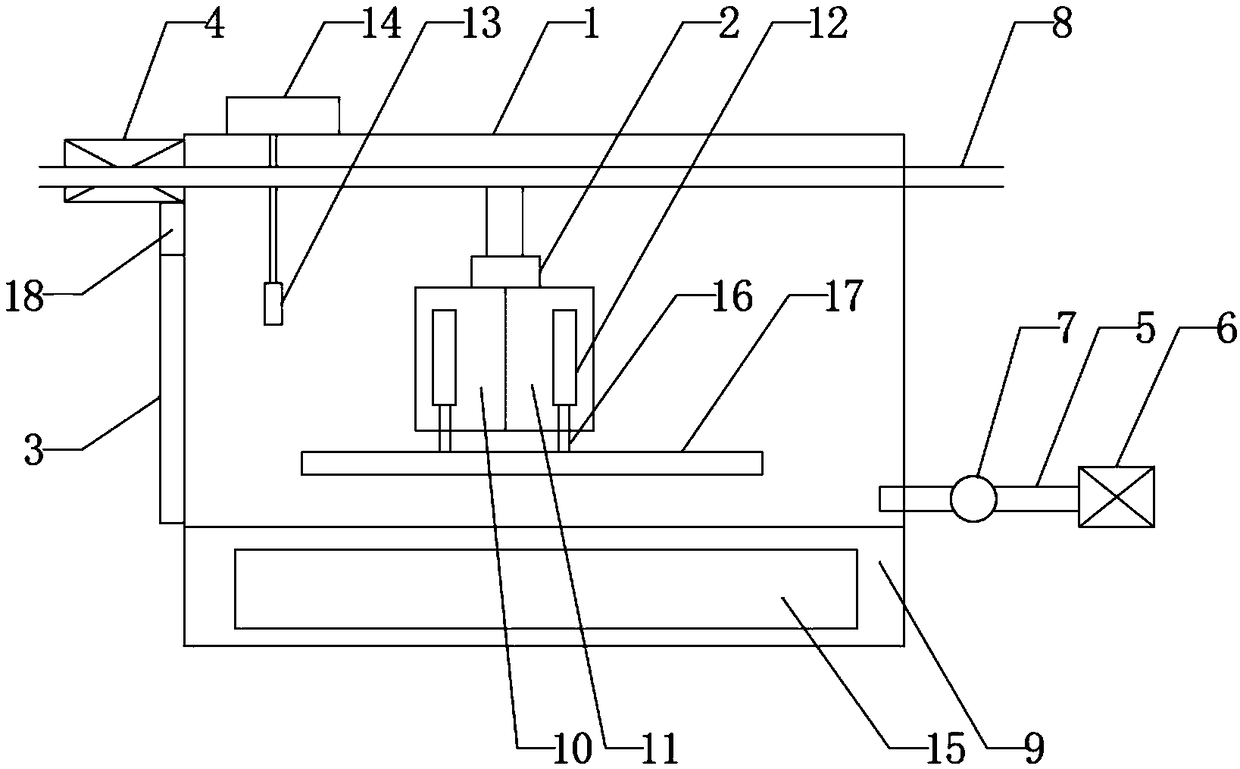

[0015] Such as figure 1 As shown, a die-casting molding device for processing magnesium alloys includes an airtight shaping chamber 1 and a movable mold 2 arranged in the airtight shaping chamber 1. The airtight shaping chamber 1 is provided with a door 3 connected to a Control the motor 4, the inner cavity of the airtight shaping chamber 1 is connected with a vacuum pump 6 through the hollow pipe 55, the hollow pipe 5 is provided with a one-way ventilation valve 7, the top of the airtight shaping chamber 1 is equipped with a feeding chain 8, and the bottom is provided with a The heating chamber 9 and the movable mold 2 are matched on the feeding chain 8. The movable mold 2 is composed of a female template 10 and a male template 11. Both the female template 10 and the male template 11 are equipped with an auxiliary heating device 12.

[0016] The airtight shaping chamber 1 is provided with a temperature sensor 13, and the temperature sensor 13 is connected with a temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com