Fast forming mold of commercial vehicle parts

A technology for forming molds and parts, applied in the field of rapid prototyping molds for commercial vehicle parts, can solve the problems of inconvenient product removal, insufficient safety measures, and high manufacturing costs, and achieve improved convenience, high work efficiency, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

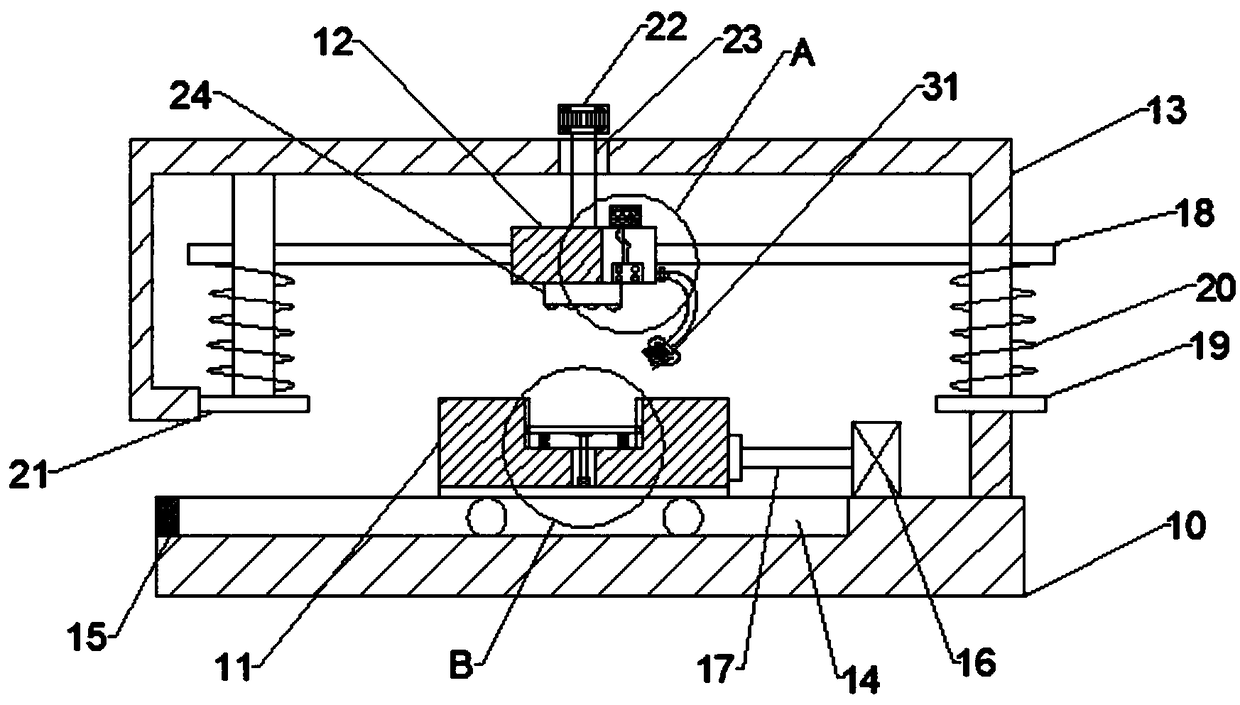

[0019] see Figure 1-3 , a rapid prototyping mold for commercial vehicle parts, including a base 10, a lower mold base 11, an upper mold base 12 and a bracket 13, the bottom of one side of the bracket 13 is fixedly connected to the upper surface of the base 10, and the top of the bracket 13 is provided with a lifter 22 , the lower side of the elevator 22 is provided with a lifting rod 23, the lifting rod 23 passes through the support 13 vertically and extends below the support 13, the bottom end of the lifting rod 23 is fixedly connected with the upper mold base 12, and the upper mold base 12 The bottom of the bottom is fixedly equipped with a punch 24, the punch 24 is used for the molding of the product, the punch 24 is supported by a support rod 18, the support rod 18 is horizontally arranged inside the support 13, and one end of the support rod 18 is fixedly connected to the support 13 Above, the other end of the support rod 18 is connected with a vertical connecting rod, t...

Embodiment 2

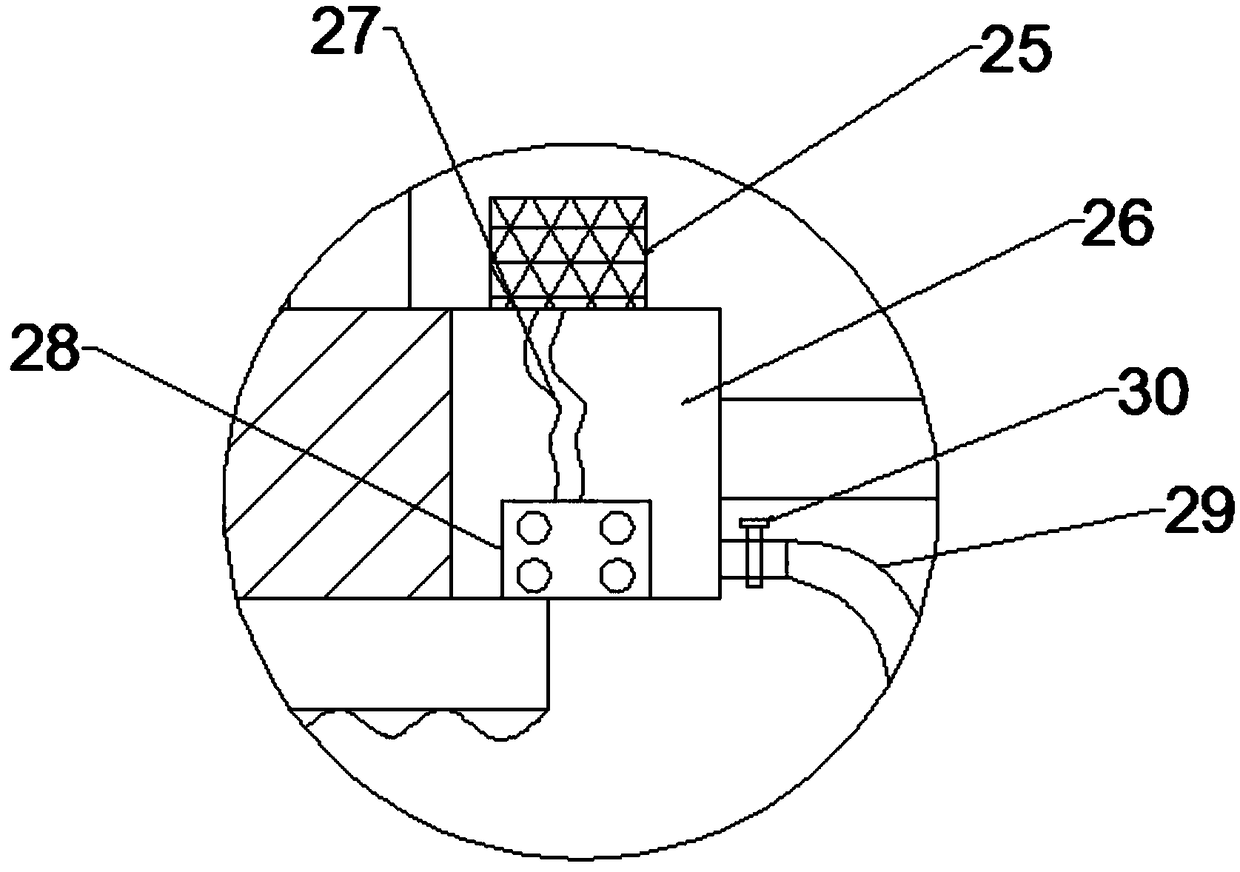

[0023] On the basis of Embodiment 1, a fan cabin 26 is provided on one side inside the upper mold base 12, a power supply 25 is fixedly placed on the outer top of the fan cabin 26, and a fan 28 is connected to the lower side of the power supply 25 through a wire 27. , one end of the blower fan 28 is connected with an air pipe 29, the air pipe 29 is provided with a valve 30, the valve 30 is used to control the flow of gas in the air pipe 29, and the end of the air pipe 29 is provided with an air nozzle 31, by starting the power supply 25 Drive the fan 28 to run, and then transport the wind generated by the fan 28 to the air nozzle 31 through the air pipe 29, and then blow the punch 24 and the die 36 during work, which can prevent external impurities from entering the die 36 , affect the surface quality of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com