Vertical wet electrostatic precipitator

A wet-type electrostatic precipitator and tower body technology, applied in the field of flue gas dust removal, can solve the problems of electric dust removal that cannot be powered normally, corona electrode dust discharge, and dust that cannot be cleaned up, so as to ensure power supply, save water, and clean good gray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

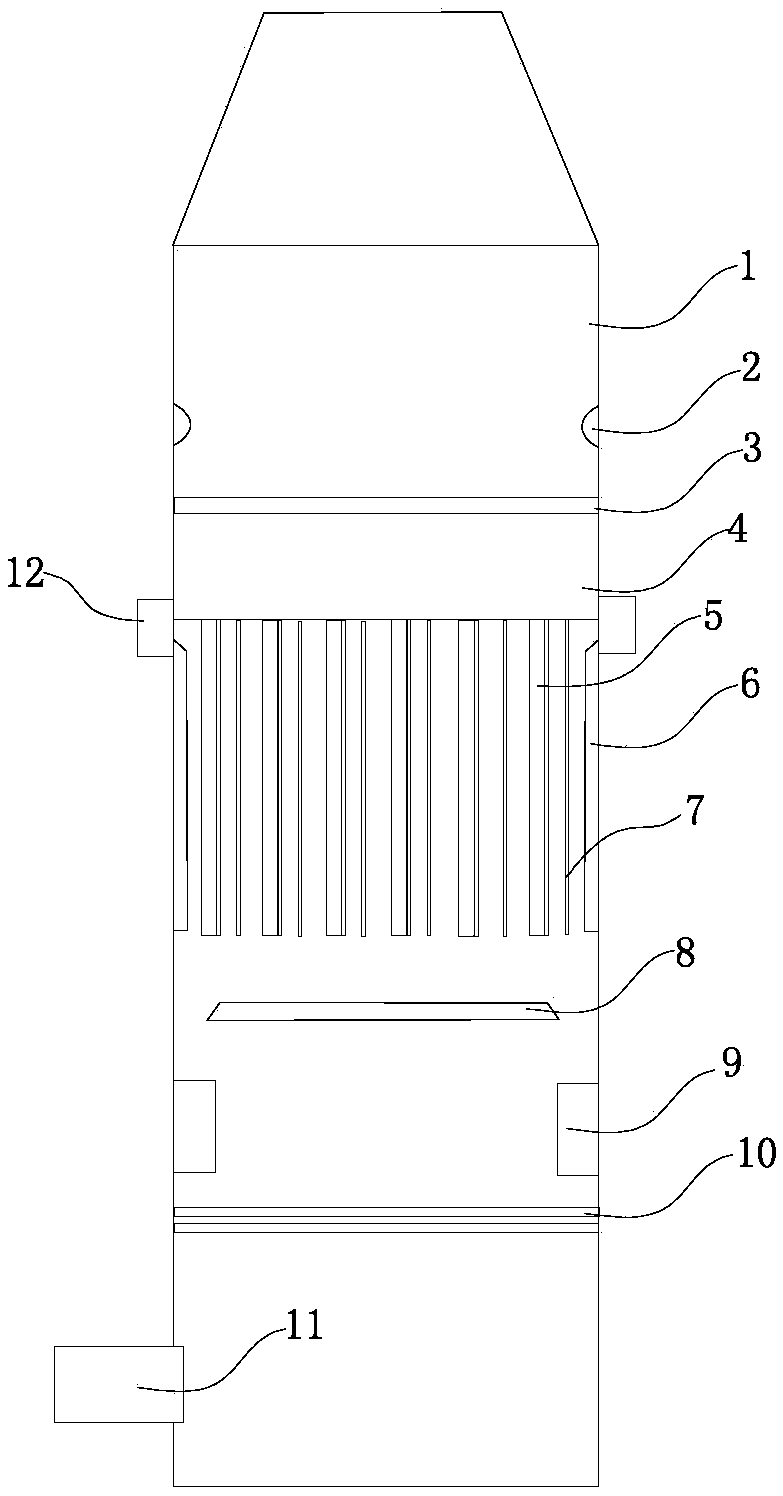

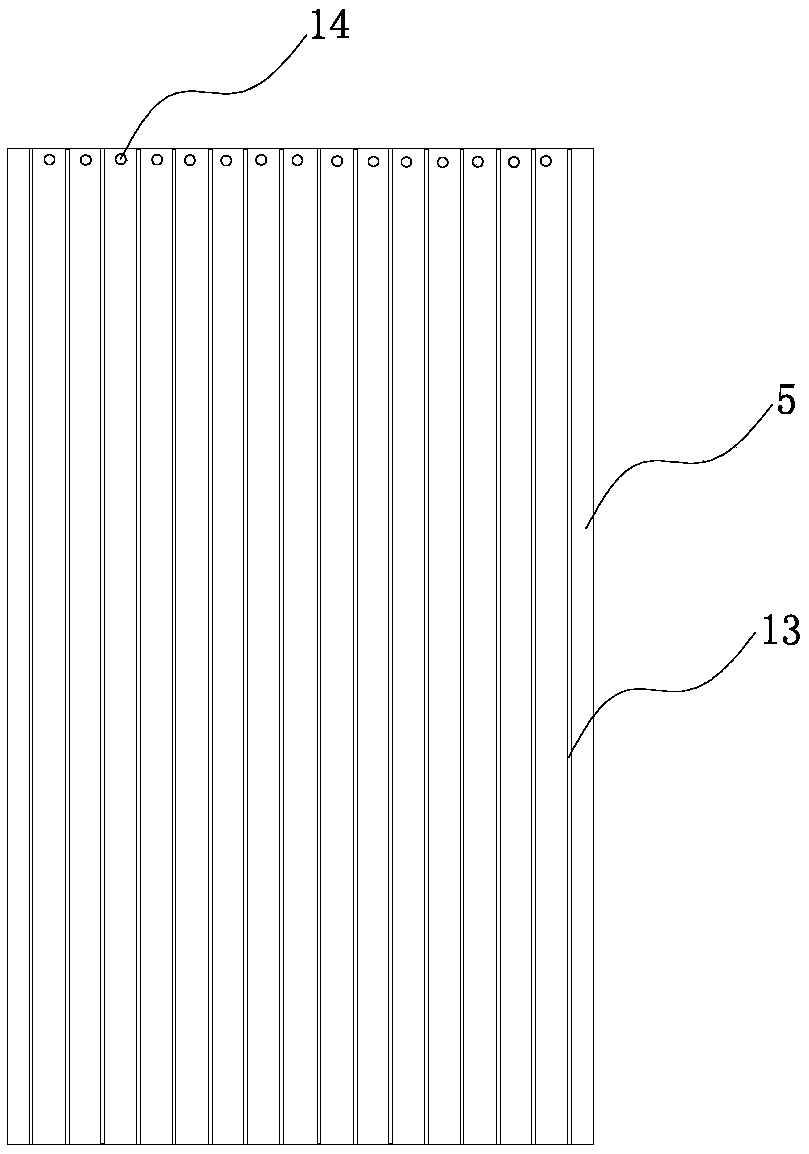

[0017] Such as figure 1 As shown, the vertical wet electrostatic precipitator of the present invention includes a tower body 1 and a pole plate area in the tower body 1, and an insulator chamber 12 is arranged above the pole plate area for fixing the broken ends of the cathode wire suspension frame, and the tower A smoke uniform distribution plate 3 is arranged at the entrance of the smoke gas in the body, and a plurality of through holes are arranged on the smoke gas uniform distribution plate 3. 2 Set on the inner wall of the tower, which includes a pair of sub-ring plates supporting each other, which can be welded on the inner wall of the tower to concentrate the airflow to the middle, increase the turbulence of the flue gas, optimize the flow field, promote local microscopic mixing, and promote The fine particles carried by the flue gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com