Vacuum reacting and testing device

A testing device and reaction technology, applied in the field of chemistry, can solve the problems of complicated connection method of sample holder, introduction of impurities, complicated operation process, etc., and achieve the effects of simple transfer and fixing method, avoidance of operation process, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

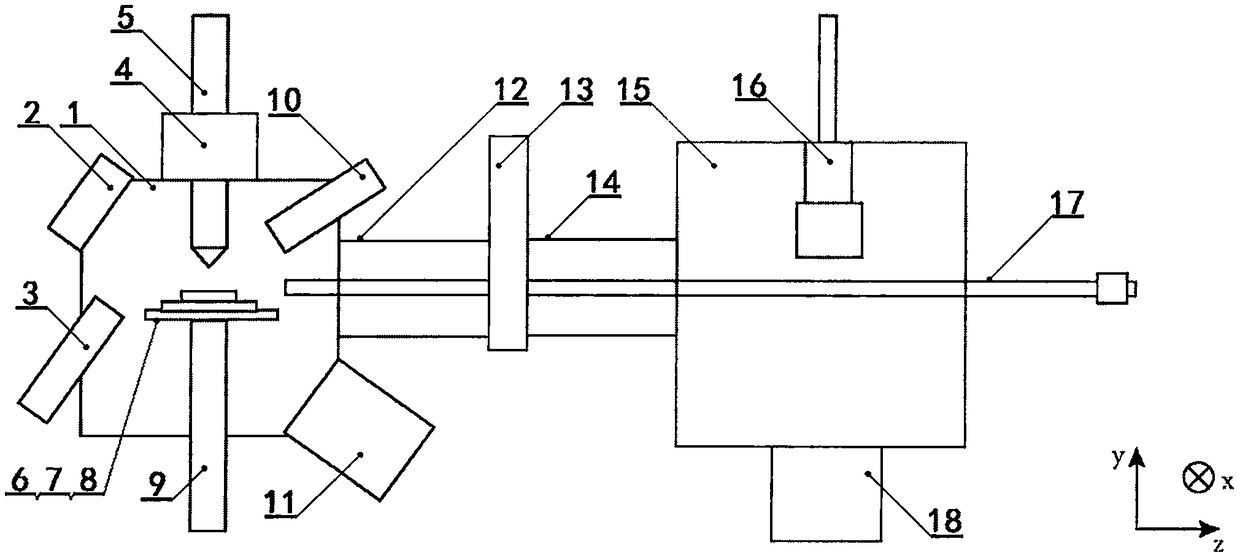

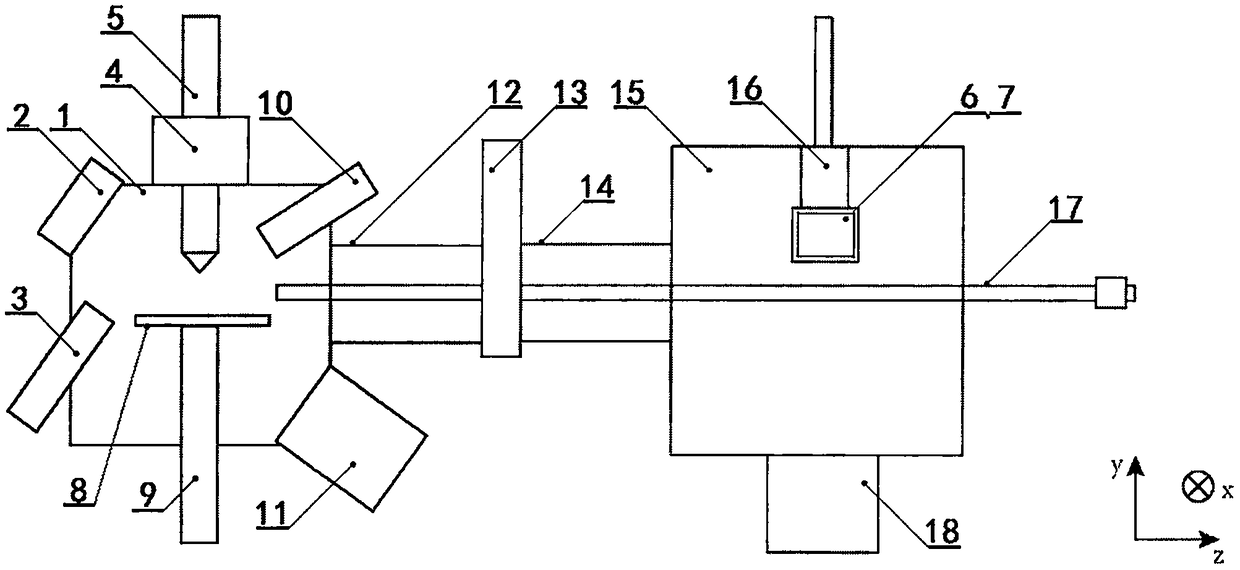

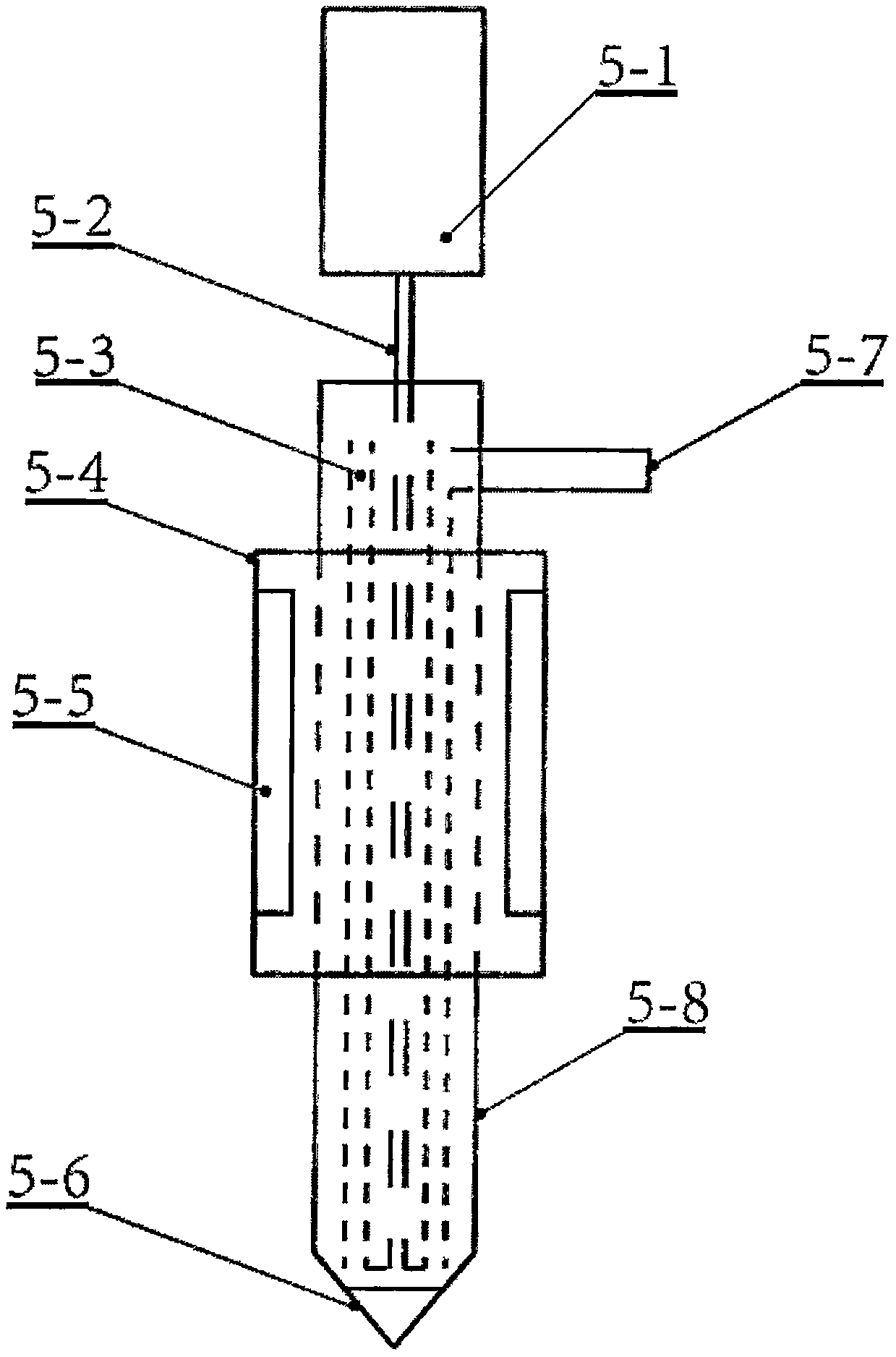

[0033] Such as figure 1 It is a schematic diagram when the sample seat of the present invention is located in the reaction chamber, such as figure 2It is a schematic diagram when the sample seat of the present invention is located in the test chamber, including a reaction chamber (1), an observation window (2), a liquid container (3), a linear drive (4), a cooling rod (5), a sample (6), a sample seat ( 7), sample table (8), metal rod (9), gas inlet (10), vacuum pump I (11), bellows I (12), gate valve (13), bellows II (14), test chamber (15 ), sample holder (16), transmission rod (17), vacuum pump II (18) and test circuit, xyz is a three-dimensional space coordinate system, and the outside of test chamber (15) is connected with vacuum pump II (18) and test circuit, vacuum pump I ( 11) An absorption pump cooled by liquid nitrogen, the reaction chamber (1), bellows I (12), gate valve (13), bellows II (14) and test chamber (15) are connected in sequence, when the gate valve (13)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com