Preparation method of polyvinylidene fluoride/TiO2 nano-sol composite ultrafiltration membrane

A polyvinylidene fluoride and nanosol technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve problems such as uneven distribution of nanometers, achieve overall uniformity and stability, overcome the phenomenon of agglomeration and precipitation, and facilitate uniform dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

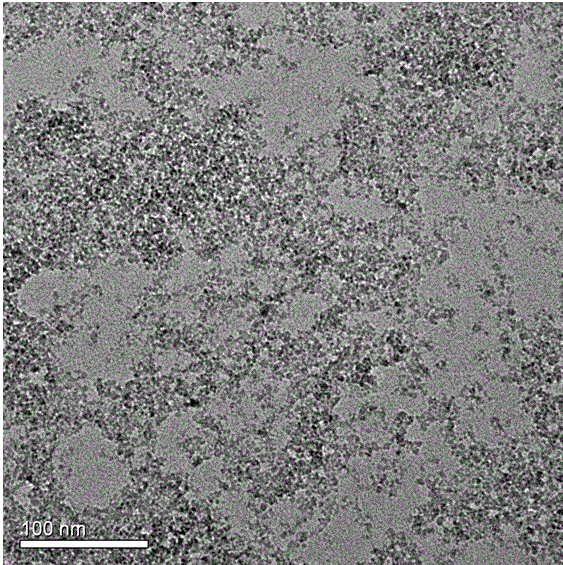

[0029](a) Tetrabutyl titanate and absolute ethanol were mixed and stirred at a ratio of 1:12 for 30 min to obtain a transparent and uniform reaction precursor. The mixed solution composed of absolute ethanol and deionized water at a ratio of 6:1 was mechanically stirred for 30 minutes, and the pH value was adjusted to 2 with dilute nitric acid or dilute hydrochloric acid, and the obtained uniform transparent solution was the reaction medium. Add the reaction precursor dropwise to the reaction medium in a water bath at 50°C, stir and sonicate for 60 minutes to obtain a light yellow emulsion, which is TiO 2 Sol solution, TiO 2 The ratio of tetrabutyl titanate to deionized water in the sol solution is 1:1.

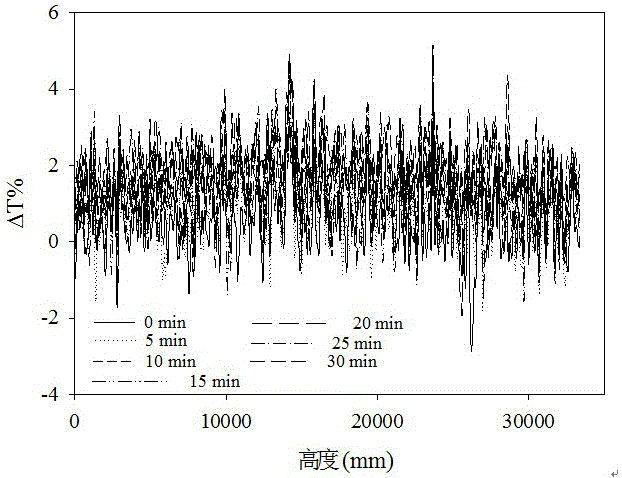

[0030] (b) Add 8% polyvinylidene fluoride to a mixed solution containing 10% pore-forming agent and 62% organic solvent and mechanically stir at 80°C for 4 days to form a homogeneous precast film solution. Then ultrasonically dispersed 30min containing 0.15%TiO 2 The mixed...

Embodiment 2

[0033] (a) Tetrabutyl titanate and absolute ethanol were mixed and stirred at a ratio of 1:12 for 30 min to obtain a transparent and uniform reaction precursor. The mixed solution composed of absolute ethanol and deionized water at a ratio of 6:1 was mechanically stirred for 30 minutes, and the pH value was adjusted to 2 with dilute nitric acid or dilute hydrochloric acid, and the obtained uniform transparent solution was the reaction medium. Add the reaction precursor dropwise to the reaction medium in a water bath at 45°C, stir and sonicate for 60 minutes to obtain a light yellow emulsion, which is TiO 2 Sol solution, TiO 2 The ratio of tetrabutyl titanate to deionized water in the sol solution is 1:0.9.

[0034] (b) Add 7% polyvinylidene fluoride to a mixed solution containing 11% pore-forming agent and 64% organic solvent and mechanically stir at 80°C for 5 days to form a homogeneous precast film solution. Then ultrasonically dispersed for 30 min containing 1% TiO 2 The...

Embodiment 3

[0037] (a) Tetrabutyl titanate and absolute ethanol were mixed and stirred at a ratio of 1:15 for 30 minutes to obtain a transparent and uniform reaction precursor. The mixed solution composed of absolute ethanol and deionized water at a ratio of 9:1 was mechanically stirred for 30 minutes, and the pH value was adjusted to 1.5 with dilute nitric acid or dilute hydrochloric acid, and the obtained uniform transparent solution was the reaction medium. Add the reaction precursor dropwise to the reaction medium in a 60°C water bath, stir and ultrasonically for 20 minutes to obtain a light yellow emulsion, which is TiO 2 Sol solution, TiO 2 The ratio of tetrabutyl titanate to deionized water in the sol solution is 1:0.8.

[0038] (b) Add 10% polyvinylidene fluoride to a mixed solution containing 8% pore-forming agent and 60% organic solvent and mechanically stir at 80°C for 4 days to form a homogeneous precast film solution. Then ultrasonically dispersed 30min containing 0.5%TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com