Cleaning composition for reverse osmosis membrane and preparation method of cleaning composition

A technology for cleaning composition and reverse osmosis membrane, which is applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology and other directions, can solve the problems of reverse osmosis membrane harm, prolong cleaning time, clean thoroughly, etc., and achieve stable pH value , The effect of strong dispersibility and strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

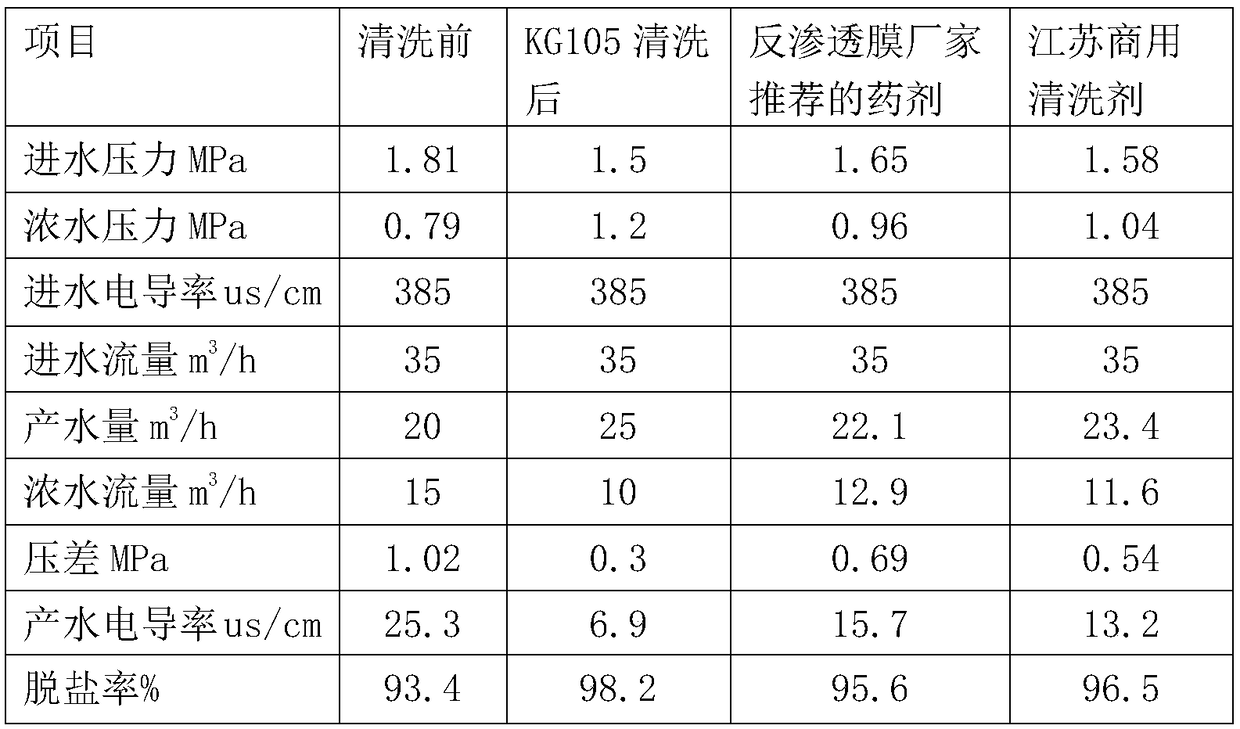

Examples

preparation example Construction

[0050] A preparation method for a cleaning composition for a reverse osmosis membrane, comprising the steps of:

[0051] A. Add NH 4 HF 2 After mixing with desalinated water, NH 4 HF 2 solution;

[0052] B. HCl, H 3 PO 4 , carboxyethylthiosuccinic acid, fatty acid methyl ester ethoxylate sulfonate were added to NH 4 HF 2 Mix in the solution until the solution is clear to obtain a clear solution;

[0053] C. Mix the clear solution with NH 3 After mixing and ripening, a cleaning agent is obtained.

[0054] Further, the pH value of the cleaning agent in step C is 1.5-4.7.

Embodiment 1

[0056] A kind of cleaning composition for reverse osmosis membrane, is made up of the component of following percentage by weight: Industrial hydrochloric acid (HCl mass fraction is 30%) 16%; Industrial phosphoric acid (H 3 PO 4 Mass fraction is 85%) 16%; Ammonium bifluoride (NH 4 HF 2 Mass fraction is 98%) 3%, carboxyethylthiosuccinic acid (CETSA mass fraction is 70%) 2%; Fatty acid methyl ester ethoxylate sulfonate 0.5%; Ammonia (the mass fraction of ammonia is 20% ) 2%; the balance is desalted water (conductivity≤10us / cm).

[0057] A preparation method for a cleaning composition for a reverse osmosis membrane, comprising the steps of:

[0058] A. After mixing ammonium bifluoride and desalinated water, ammonium bifluoride solution is obtained;

[0059] B. Add industrial hydrochloric acid, industrial phosphoric acid, carboxyethylthiosuccinic acid, and fatty acid methyl ester ethoxylate sulfonate successively into the ammonium bifluoride solution and mix until the solution...

Embodiment 2

[0063] A kind of cleaning composition for reverse osmosis membrane, is made up of the component of following percentage by weight: Industrial hydrochloric acid (HCl mass fraction is 30%) 10%; Industrial phosphoric acid (H 3 PO 4 Mass fraction is 85%) 10%; Ammonium bifluoride (NH 4 HF 2 Mass fraction is 98%) 2%; Carboxyethylthiosuccinic acid (CETSA mass fraction is 70%) 2%; Fatty acid methyl ester ethoxylate sulfonate 0.5%; Ammonia (the mass fraction of ammonia is 20% ) 1%; the balance is desalted water (conductivity ≤ 10us / cm).

[0064] A preparation method for a cleaning composition for a reverse osmosis membrane, comprising the steps of:

[0065] A. After mixing ammonium bifluoride and desalinated water, ammonium bifluoride solution is obtained;

[0066] B. Add industrial hydrochloric acid, industrial phosphoric acid, carboxyethylthiosuccinic acid, and fatty acid methyl ester ethoxylate sulfonate successively into the ammonium bifluoride solution and mix until the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com