Rubbing-type oil palm fruit millerator

A technology of oil palm fruit and separator, which is applied in the field of agricultural machinery, can solve the problems of low kernel whole rate, complex separation of shell and kernel of oil palm kernel, and many impurities, and achieves obvious effect, easy maintenance and adjustment, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

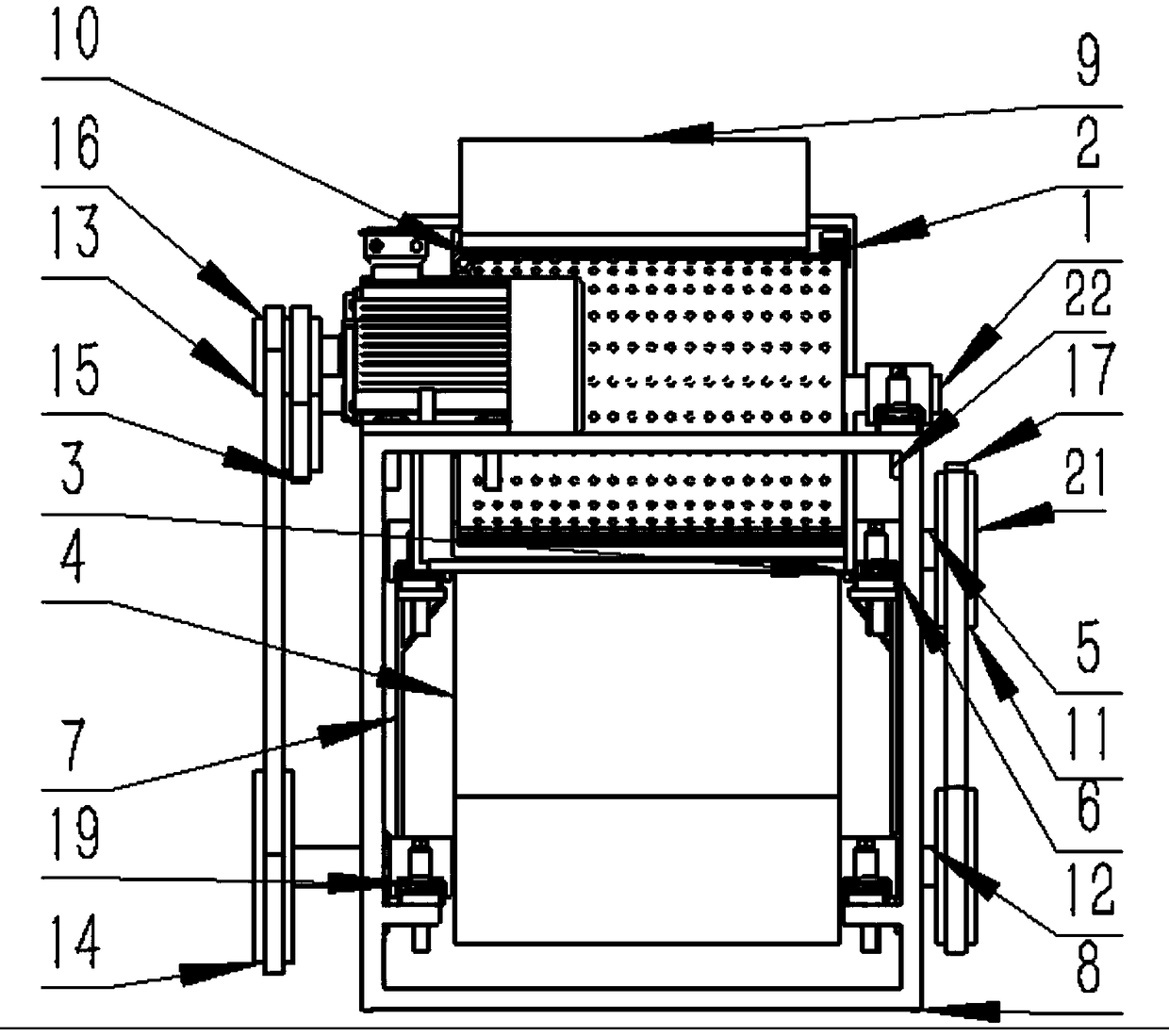

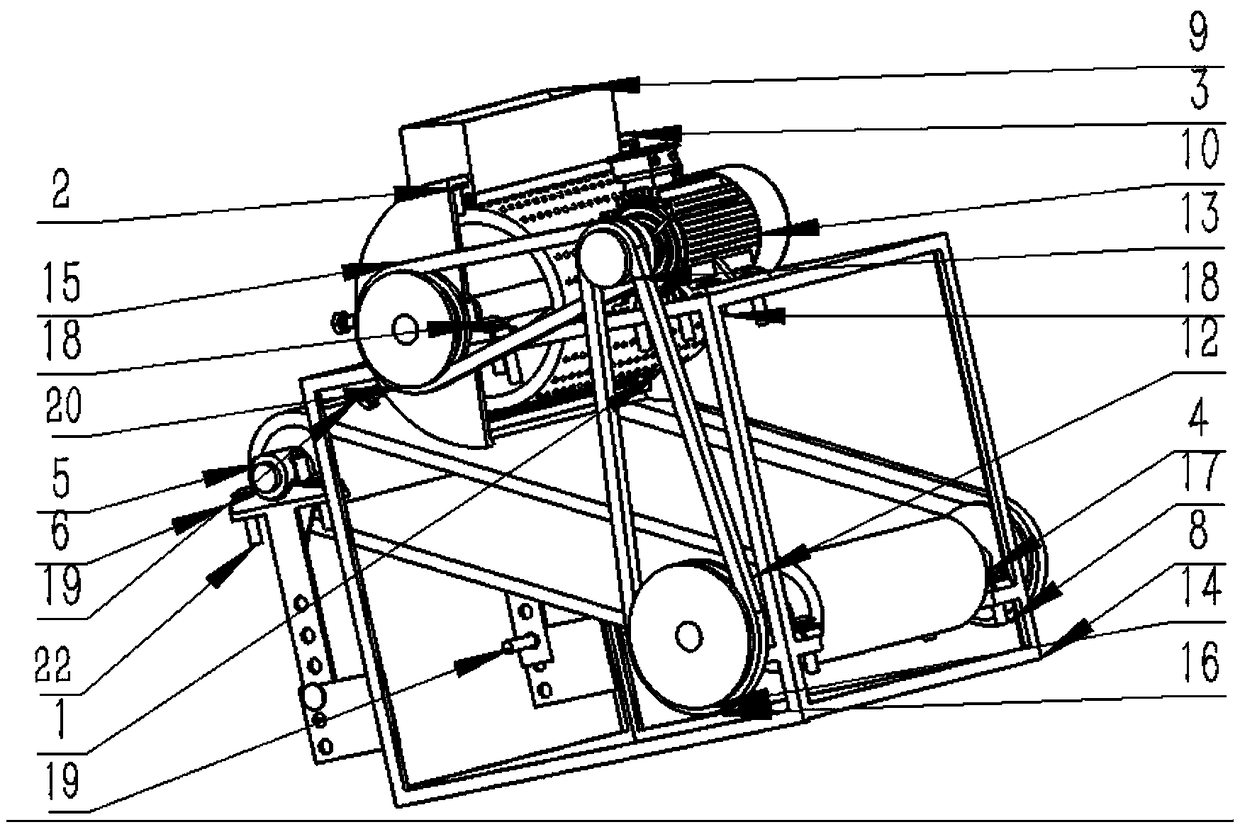

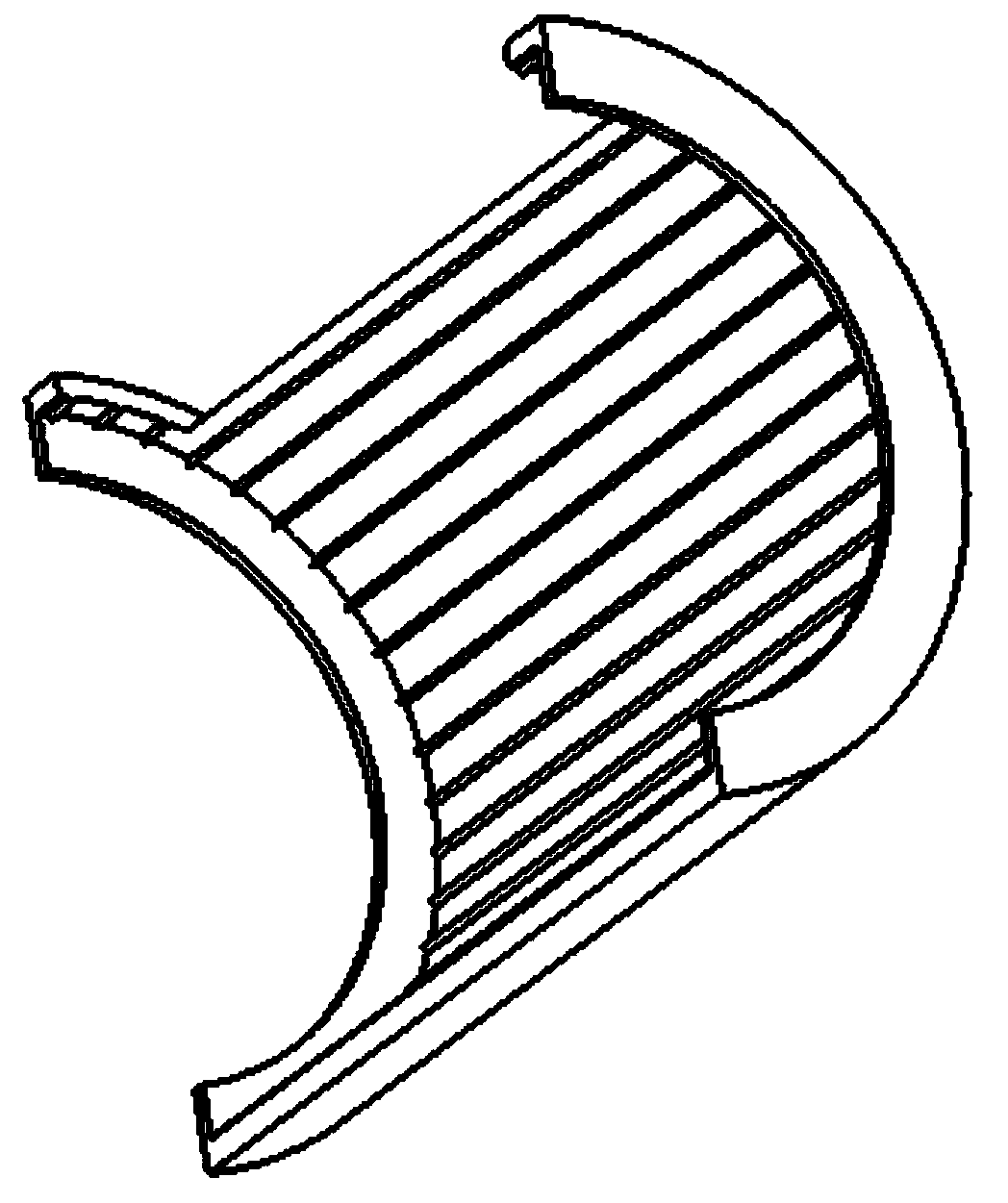

[0017] A rubbing type oil palm fruit crushing and separating machine provided by the present invention mainly includes a feeding device, a shell breaking device, a shell kernel separating device, a transmission system and a frame; wherein the feeding device is located above the drum frame (3), mainly composed of The hopper (9) and the drum frame (3) are composed; the transmission device is mainly composed of the motor (10), the upper roller (5), the lower roller (12), the motor pulley (13), the drum pulley (20), the lower roller The right pulley (11), the lower roller left pulley (14), the upper roller pulley (21), the upper transmission belt (15), the lower transmission belt (16) and the roller transmission belt (17); powered by the motor (10) The upper conveyor belt (15) drives the roller pulley (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com