Combined rolling and pressing method and device for the implementation thereof

An extrusion device and combined technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as severe wear, and achieve the effects of reducing return loss, improving quality, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

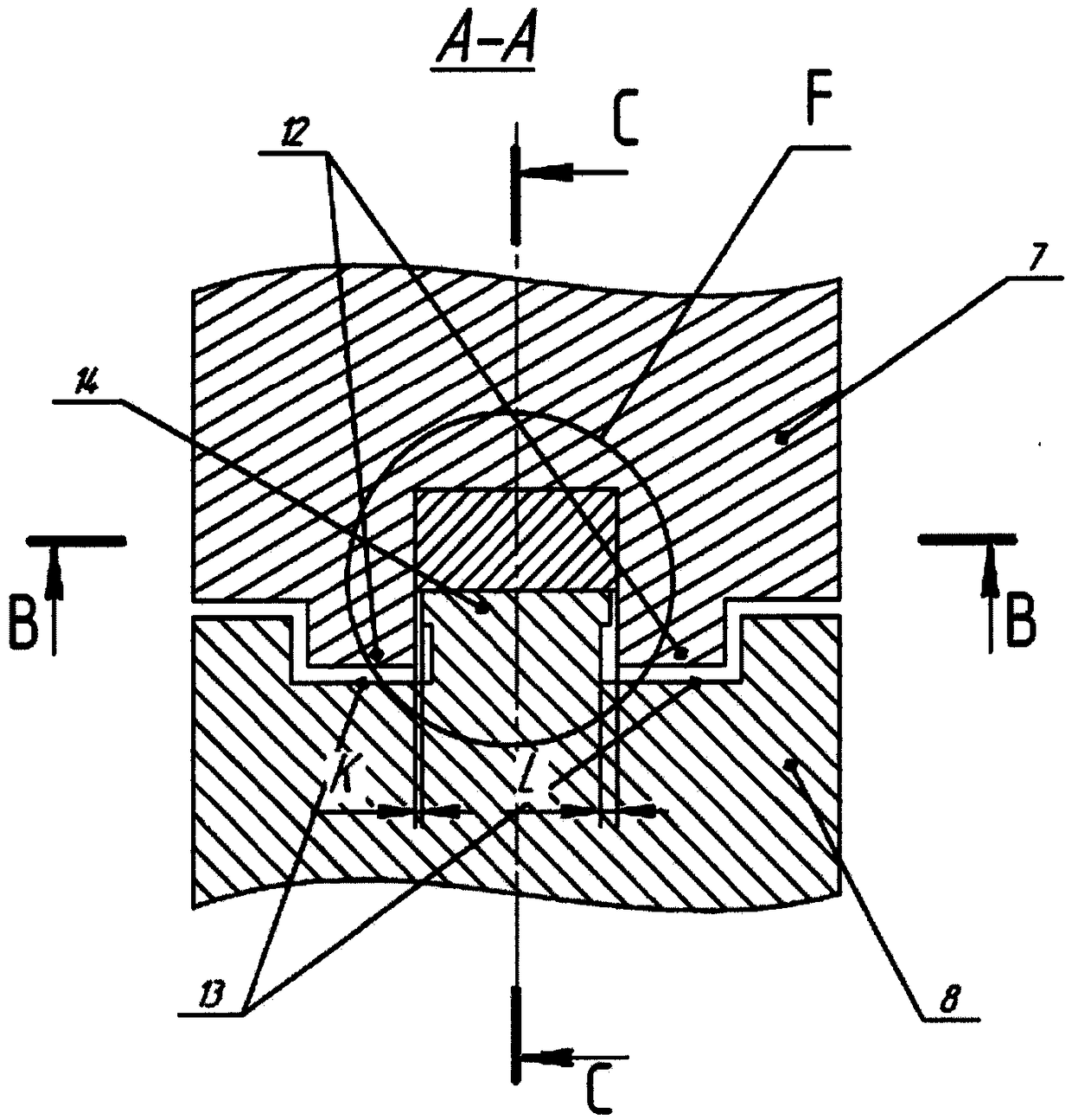

[0063] Combined rolling extrusion device ( figure 1 )include:

[0064] A holding furnace 1 with liquid aluminum or aluminum alloy 2; a rotating mold 3 forming a cast billet 4 of infinite length; a temperature control device 5 for the cast billet; rollers of guide elements 6, grooved rollers 7 and finned rollers 8 and Die 9, grooved roll 7 and finned roll 8 and die 9 form a closed working gauge for extruding semi-finished product 10 ( figure 2 ); and semi-finished product cooling device 11.

[0065] The cylindrical surface of the grooved roll 7 is provided with fins 12 coupled with grooves 13 formed on the cylindrical surface of the finned roll 8 . The fins and grooves on the surfaces of the rollers 7 and 8 form a labyrinth coupling of the rollers to each other. During operation of the unit, deformed areas are created within the working gauge due to actively acting frictional forces. The fins 14 of the roller 8 are in the same deformation zone ( figure 2 The shaded area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com