High-power LED linear constant-current driving control chip

A linear constant current drive and control chip technology, applied in the field of microelectronics, can solve the problems of inconsistent conduction state of MOS tubes, low efficiency of the whole machine, etc., and achieves simple PCB layout and wiring, reduced consistency requirements, and reduced useless power. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

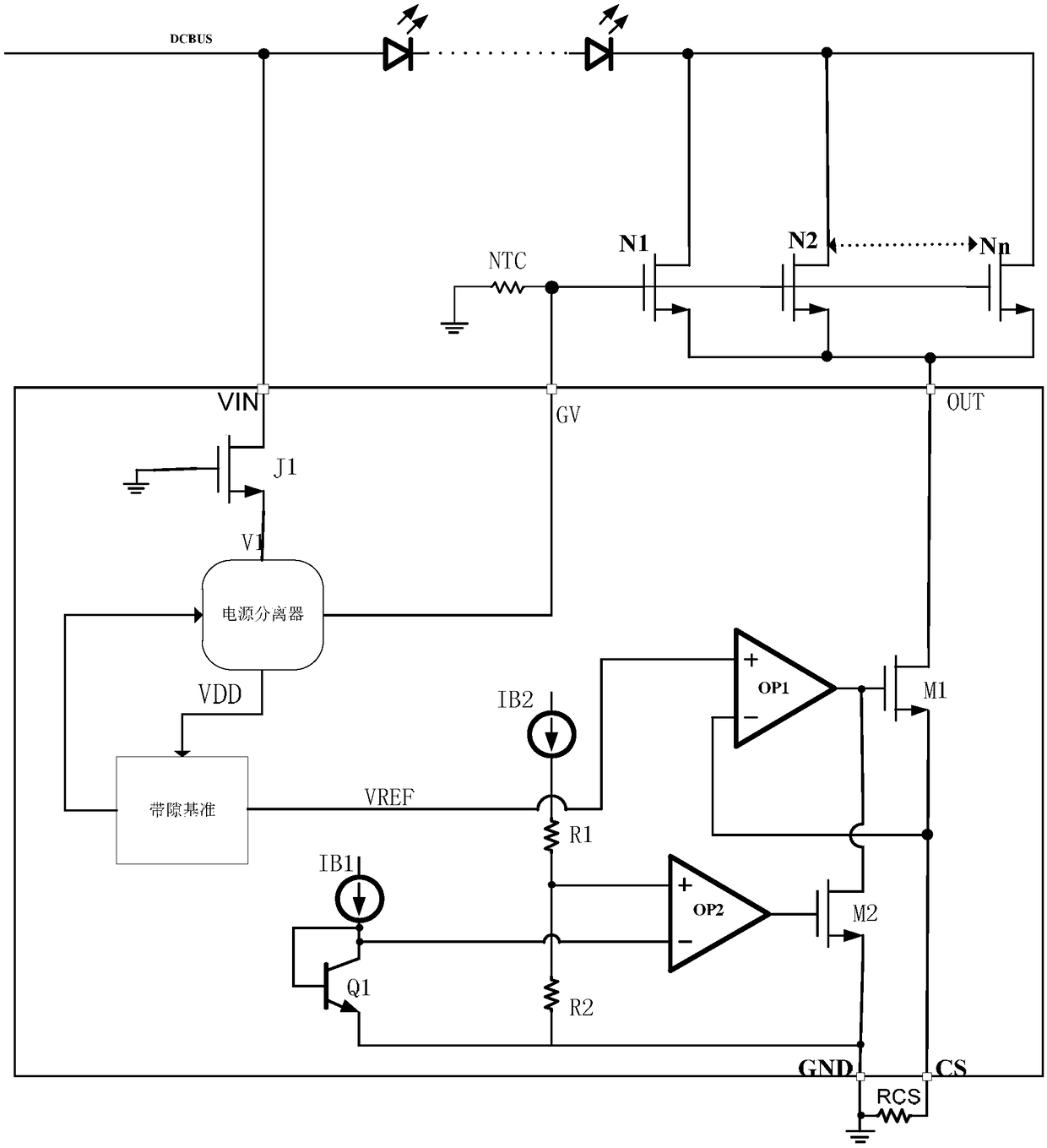

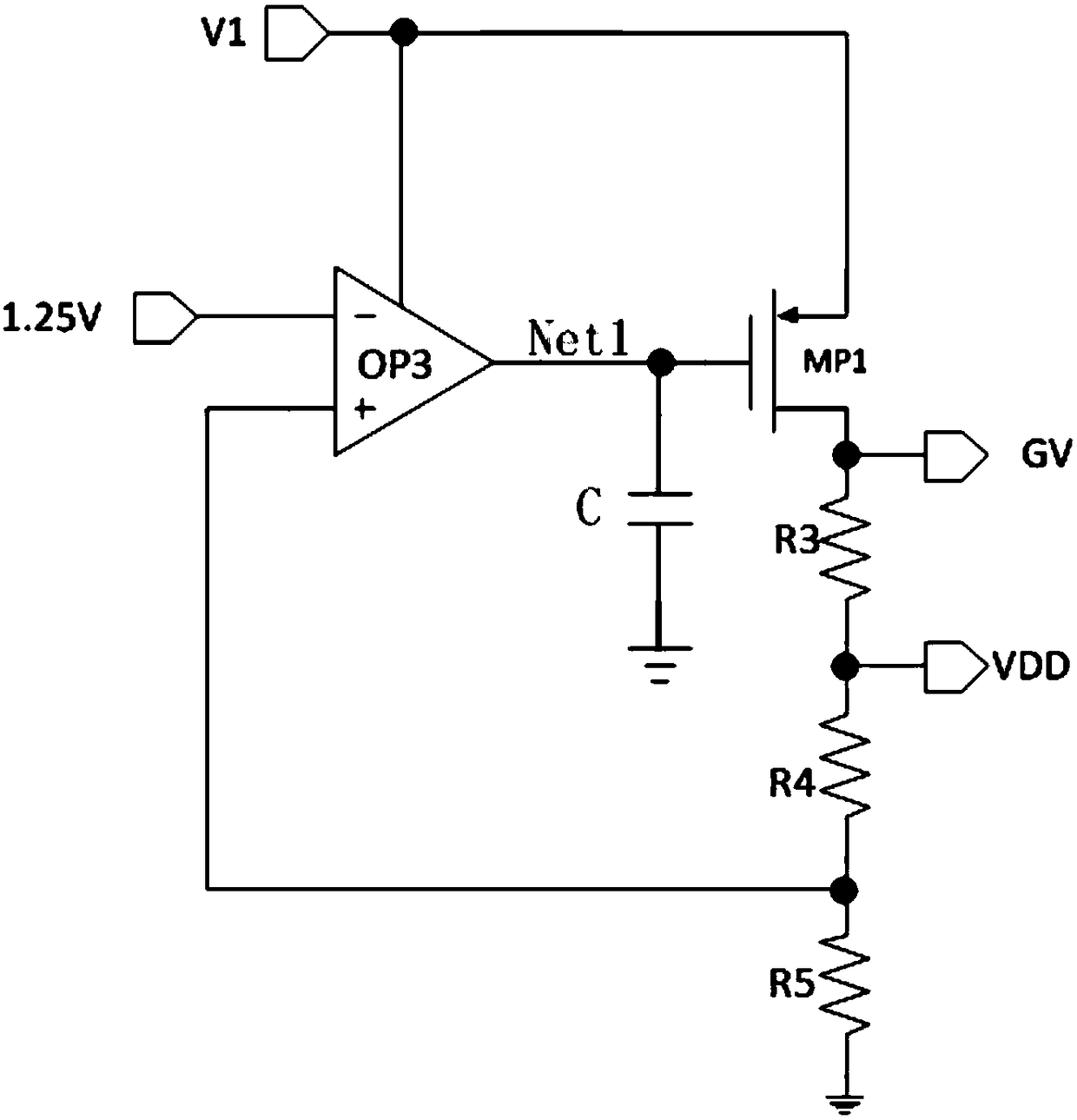

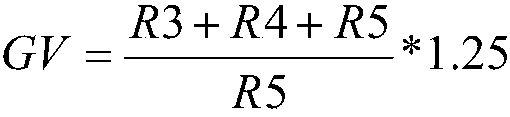

[0021] Such as figure 1 As shown, the high-power LED linear constant current drive control chip is characterized in that it includes a DC bus DUBUS, a plurality of series-connected LED lamp beads, and a number of external power tubes (N1-Nn). The DC bus DCBUS Connect the first end of the first LED lamp bead to the drain of JFET tube J1, and the second end of the last LED lamp bead to the drains of all external power tubes (N1-Nn), all external power tubes The gates of (N1-Nn) are commonly connected to the first end of the thermistor NTC, the second end of the thermistor NTC is grounded, the gate of the JFET tube J1 is grounded, and the source of the JFET tube J1 is connected The input terminal of the power splitter, the VDD output terminal of the power splitter is connected to the bandgap reference module, the GV output terminal of the power splitter is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com