One-step molded light-duty PVT (photovoltaic-solar-thermal) assembly and preparation method therefor

A component and lightweight technology, applied in the field of one-time molding lightweight PVT components and its preparation, to achieve the effects of avoiding heavy weight, reducing production costs, and reducing component weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

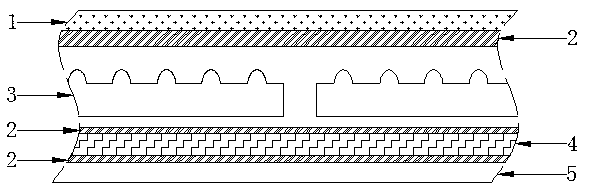

[0033] Such as figure 1 As shown, a one-time molding lightweight PVT assembly, the PVT assembly sequentially includes a front protective layer 1, a photovoltaic cell string layer 3, an isolation layer 4 and a heat collection layer 5, and an adhesive layer 2 is provided between adjacent two layers, and the PVT assembly After each layer is superimposed, an edge banding strip is provided on the outside.

Embodiment 2

[0035] Such as figure 1 As shown, a one-time molding lightweight PVT component, the PVT component sequentially includes a transparent PET polymer film front protective layer 1 with a thickness of 0.5 mm from the light-facing surface to the back-light surface, and a POE adhesive layer 2 with a thickness of 0.5 mm. A photovoltaic cell string layer 3 prepared by serial welding of 60 monocrystalline cells on the front side, an EVA adhesive layer 2 with a thickness of 0.5 mm, a PVDF isolation layer 4 with a thickness of 0.3 mm, and an EVA adhesive layer 2 with a thickness of 0.5 mm. 5mm heat collecting layer 5 of single-sided inflated aluminum alloy plate, after each layer is stacked, a butyl rubber edge band is set outside the PVT module.

Embodiment 3

[0037] Such as figure 1 As shown, a one-time molding lightweight PVT component, the PVT component sequentially includes a tempered glass front protective layer 1 with a thickness of 0.5mm from the light-facing surface to the backlight surface, and a POE adhesive layer 2 with a thickness of 0.5mm, consisting of 72 single-piece The photovoltaic cell string layer 3 prepared by serial welding on the front side of the crystal cell, the EVA adhesive layer 2 with a thickness of 0.5 mm, the PVDF isolation layer 4 with a thickness of 0.3 mm, the EVA adhesive layer 2 with a thickness of 0.5 mm, and the single layer with a thickness of 5 mm Surface inflatable aluminum alloy plate heat collecting layer 5, and after each layer is stacked, butyl rubber edge banding is set outside the PVT module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com