Direct shear test system for seasonally frozen ground and test method thereof

A test system and seasonal technology, applied in the field of frozen soil shear test equipment, can solve the problems of no direct shear test and frozen soil field simulation, and no realization of on-site freezing and thawing cycle of soil mass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

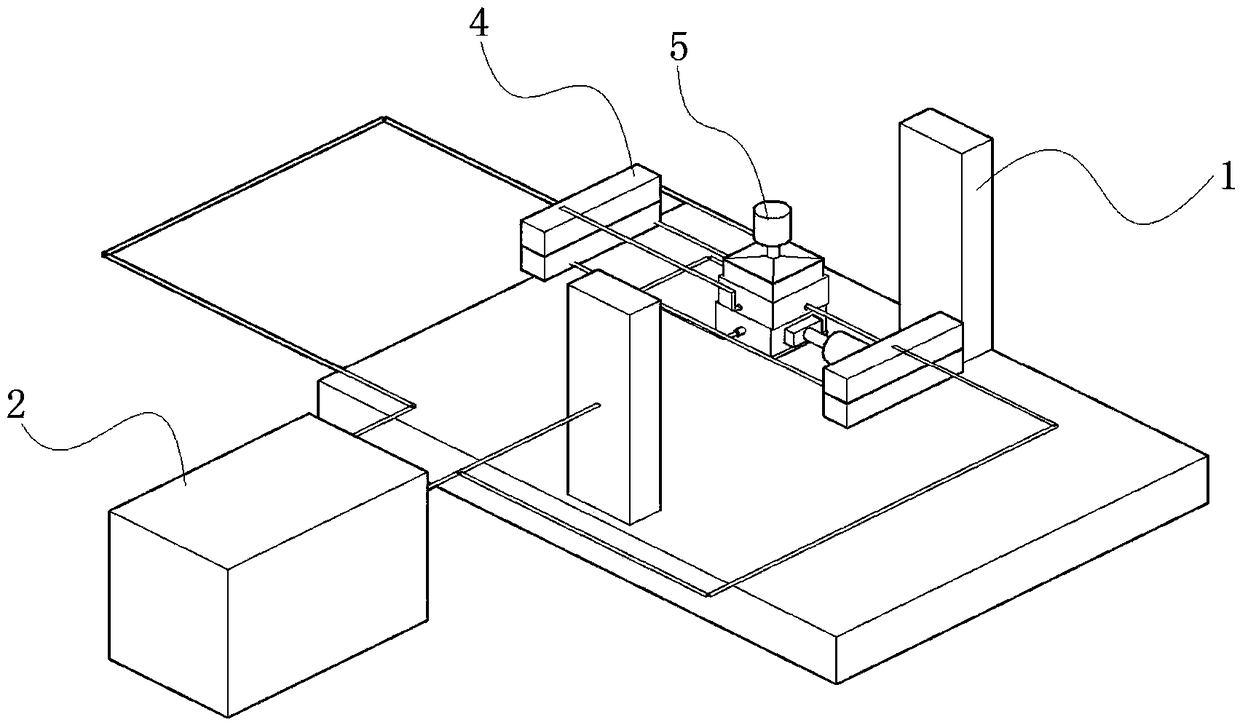

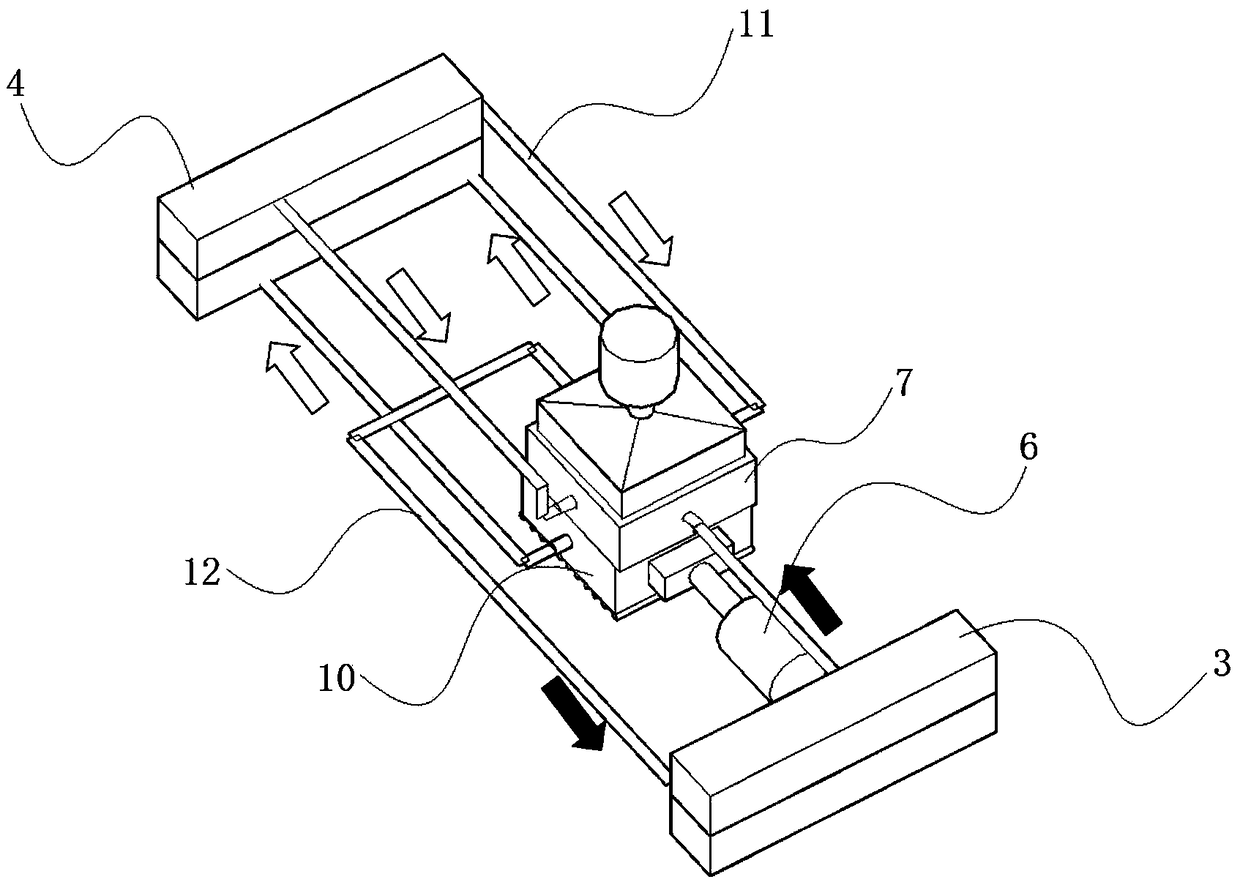

[0030] see figure 1 , this embodiment discloses a seasonal frozen soil direct shear test system, including a shear box arranged on a test platform, a freeze-thaw cycle system and a loading system.

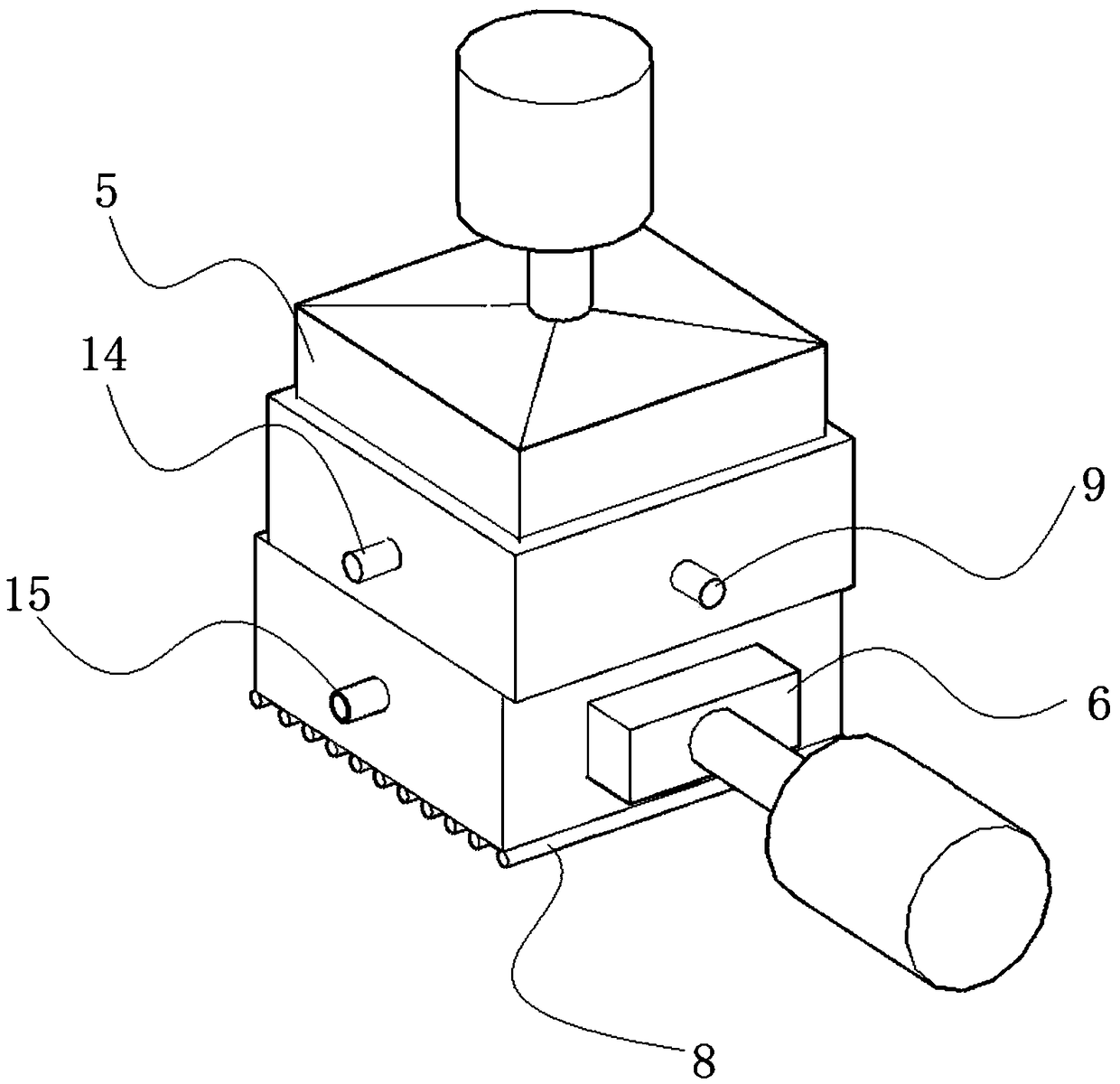

[0031] see Figure 4 , the shear box is made of PEEK resin (polyether ether ketone). The shear box as a whole is a rectangular box. The four side walls of the rectangular box are sequentially the first side wall, the second side wall, the third side wall and the fourth side wall. A liquid nitrogen cooling chamber is enclosed in the second side wall and the fourth side wall of the shear box. The shear box can be split into an upper shear box 7 and a lower shear box 10 . The upper shear box 7 is a rectangular frame as a whole. Heating nitrogen vents 9 are provided on the first side wall and the third side wall of the upper shear box 7 . A liquid nitrogen injection port 14 is provided on the second side wall and the fourth side wall of the upper shear box 7 . The lower shear bo...

Embodiment 2

[0038] This embodiment discloses a kind of test method about the seasonal frozen soil direct shear test system described in embodiment 1, comprising the following steps:

[0039] 1) Put soil in the shear box and compact it. Open the freeze-thaw cycle system to realize the freeze-thaw cycle of the soil.

[0040] 2) The automatic vertical pressing device 5 applies a vertical load to the sample, and the automatic horizontal pushing device 6 applies a horizontal thrust to the lower shear box 10 .

[0041] 3) The data acquisition instrument 2 collects and records shear stress data and shear displacement data. After the data acquisition instrument 2 preliminarily processes the data, it transmits the data to the computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com