Track bed surface waterproof layer expansion joint structure

A technology for expansion joints and subgrade surfaces, applied in the direction of tracks, roads, ballast layers, etc., can solve problems affecting the smoothness and driving safety of ballastless tracks, low freeze-thaw resistance and durability, and weak interface adhesion. problems, to achieve good water immersion stability, good resistance to displacement deformation and anti-peeling strength, and good waterproof and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

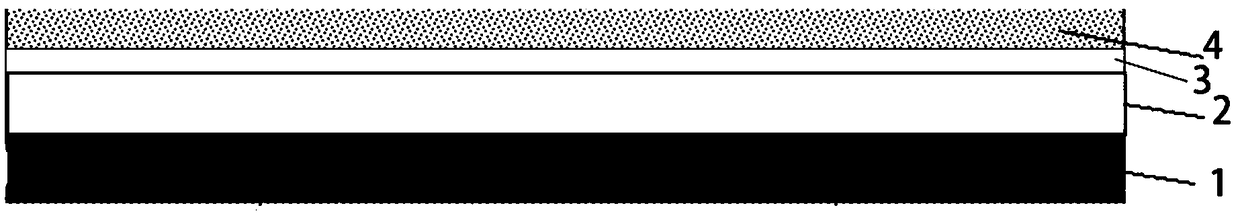

[0016] The expansion joint structure of the waterproof layer of the track subgrade in this embodiment includes a caulking plate 1, a backing material 2, a neoprene hollow elastic tube 3 and a sealant layer 4 arranged in the expansion joint from bottom to top;

[0017] The backing material is prepared in the following manner:

[0018] Mix acetone and epoxy resin and stir evenly, then add iron powder and aluminum powder, stir evenly, let stand for 2 hours, discharge some air bubbles, then add triethylenetetramine, stir evenly quickly, pour into the mold and let stand at a temperature of 20°C 25min, and then keep warm at 100°C for 2.5h; the mass ratio of the iron powder to the epoxy resin is 3:1; the mass ratio of the aluminum powder to the epoxy resin is 2:1;

[0019] The hollow elastic tubes are longitudinally distributed along the expansion joints, and the caulking plate 1, the backing material 2, the neoprene hollow elastic tubes 3 and the sealant layer 4 are bonded and fixed...

Embodiment 2

[0024] The expansion joint structure of the waterproof layer of the track subgrade in this embodiment includes a caulking plate 1, a backing material 2, a neoprene hollow elastic tube 3 and a sealant layer 4 arranged in the expansion joint from bottom to top; The backing material is prepared by:

[0025] Mix acetone and epoxy resin and stir evenly, then add iron powder and aluminum powder, stir evenly, let it stand for 2 hours, discharge some air bubbles, then add triethylenetetramine and stir evenly, pour it into the mold and let it stand at a temperature of 30°C 35min, and then keep warm at 100°C for 3.5h; the mass ratio of the iron powder to the epoxy resin is 4.5:1; the mass ratio of the aluminum powder to the epoxy resin is 3.5:1;

[0026] The hollow elastic tubes are longitudinally distributed along the expansion joints, and the caulking plate 1, the backing material 2, the neoprene hollow elastic tubes 3 and the sealant layer 4 are bonded and fixedly connected to the ex...

Embodiment 3

[0031] The expansion joint structure of the waterproof layer of the track subgrade in this embodiment includes a caulking plate 1, a backing material 2, a neoprene hollow elastic tube 3 and a sealant layer 4 arranged in the expansion joint from bottom to top; The backing material is prepared by:

[0032] Mix acetone and epoxy resin and stir evenly, then add iron powder and aluminum powder, stir evenly, let stand for 2 hours, discharge some air bubbles, then add triethylenetetramine, stir evenly quickly, pour into the mold and let stand at a temperature of 20°C 35min, and then keep warm at 100°C for 2.5h; the mass ratio of the iron powder to the epoxy resin is 4.5:1; the mass ratio of the aluminum powder to the epoxy resin is 3.5:1;

[0033]The hollow elastic tubes are longitudinally distributed along the expansion joints, and the caulking plate 1, the backing material 2, the neoprene hollow elastic tubes 3 and the sealant layer 4 are bonded and fixedly connected to the expansi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com