Amino polyether polyol, preparation method thereof, polyurethane rigid foam and preparation method thereof

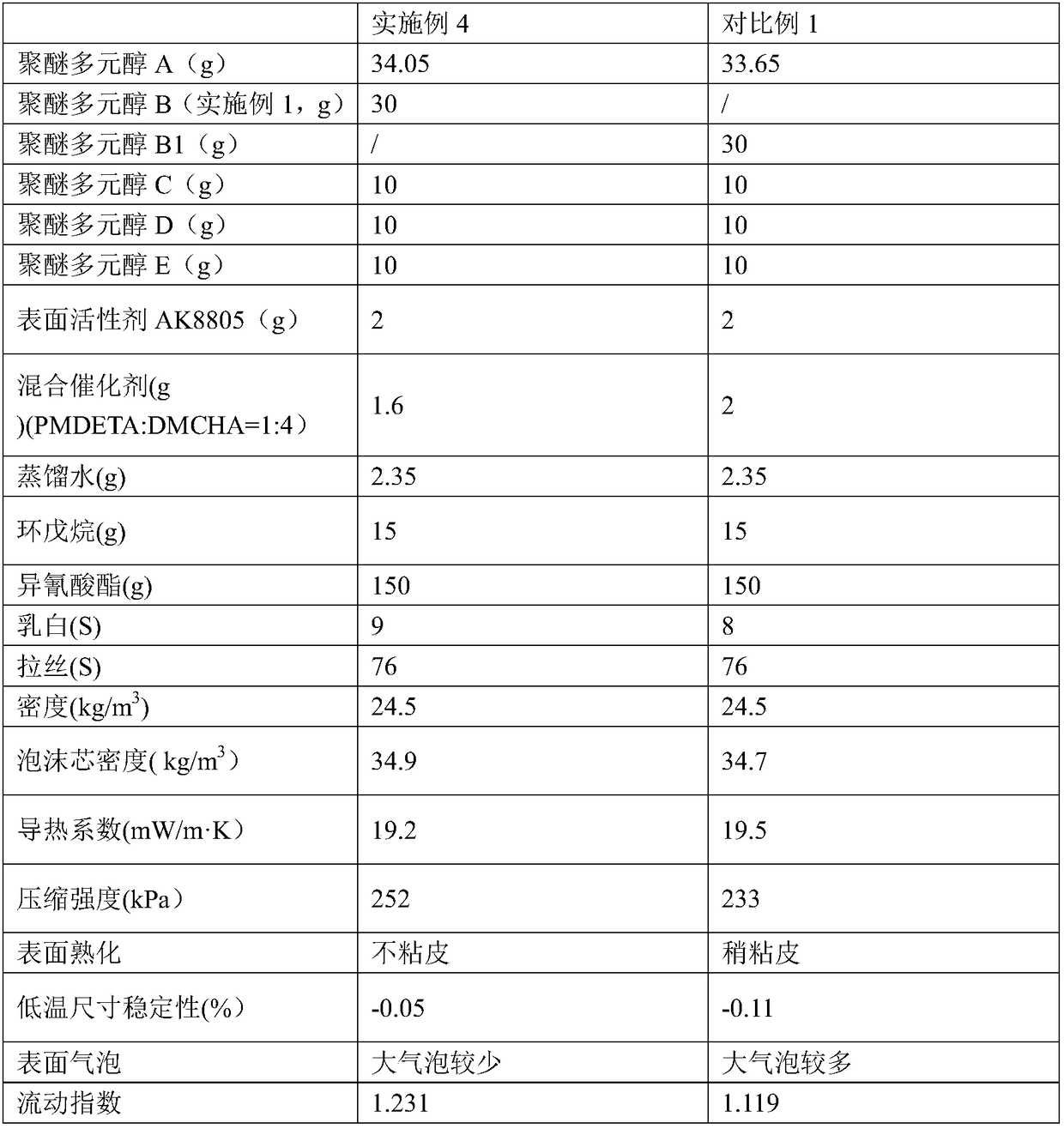

A technology of polyether polyol and amino polyether, which is applied in the field of polyols, can solve the problems of OTDA price soaring, surface aging surface bubble deterioration, OTDA price rising, etc., and achieve good isotropy and compatibility Improvement and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

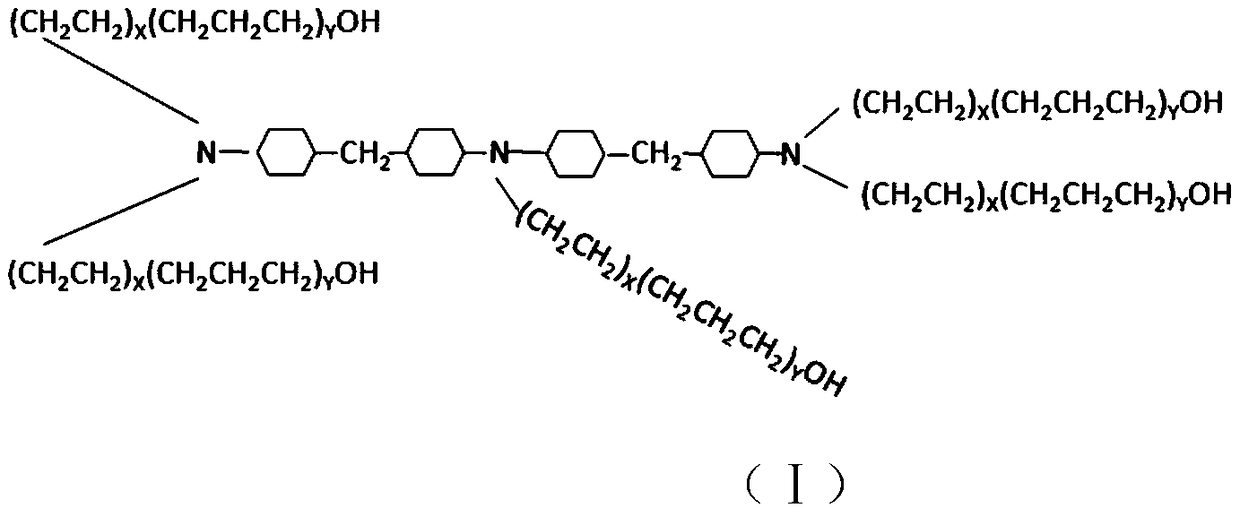

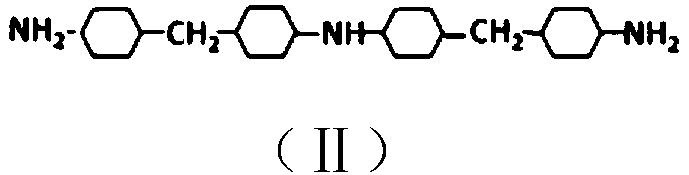

[0074] A preparation method of amino polyether polyol, the steps are:

[0075] 1) Add water (24048.9g, 1336.05mol) and 4,4'-diaminodicyclohexylmethane conjugate (1499.7g, 3.74mol) into the reaction kettle, replace with nitrogen and test the pressure, start stirring and heat to 110°C . Add 400 g of propylene oxide into the reactor by metering a flow rate of 800 g / h. Then the reaction was continued for 1 h, and then the temperature was raised to 105° C. for another 1 h.

[0076] 2) Add 20.9 g of potassium hydroxide aqueous solution (50 wt%). Water was removed under vacuum at 115° C. for 2 h. Add remaining propylene oxide 468g by flow rate 600g / h metering. After continuing to react for 1h, the temperature was raised to 135°C for another 1h.

[0077] 3) Add 36.7g of 50wt% phosphoric acid aqueous solution to remove K ions, and process to obtain the final product polyol. In the obtained polyol, X and Y are 0 and 7 respectively, and the viscosity at 20° C. is 39155 cps. The hyd...

Embodiment 2

[0079] A preparation method of amino polyether polyol, the steps are:

[0080] 1) Add water (4424.83g, 245.82mol) and 4,4'-diaminodicyclohexylmethane conjugate (184.37g, 0.46mol) into the reaction kettle, replace with nitrogen and test the pressure, start stirring and heat to 90°C . Add 80 g of propylene oxide into the reactor by metering a flow rate of 800 g / h. Then continue to react for 0.5h, then raise the temperature to 100°C and react for another 0.5h.

[0081] 2) Add 2.86 g of potassium hydroxide aqueous solution (30 wt%). The water was removed under vacuum at 100° C. for 1 h. Add remaining propylene oxide 80g by metering flow rate 600g / h. After continuing to react for 1h, the temperature was raised to 130°C for another 1h.

[0082] 3) Add 7.51 g of 20 wt % phosphoric acid aqueous solution to remove K ions, and process to obtain the final product polyol. In the obtained polyol, X and Y are 0 and 4 respectively, and the viscosity at 20° C. is 35106 cps. The hydroxyl...

Embodiment 3

[0084] A preparation method of amino polyether polyol, the steps are:

[0085] 1) Add water (15097.01g, 838.72mol) and 4,4'-diaminodicyclohexylmethane conjugate (1136.33g, 2.83mol) into the reaction kettle, replace with nitrogen and test the pressure, start stirring and heat to 110°C . Add 461.53 g of oxyalkylene (mass ratio of propylene oxide to ethylene oxide: 1:3) into the reactor at a flow rate of 800 g / h. Then the reaction was continued for 2 hours, and then the temperature was raised to 110° C. for another 2 hours.

[0086] 2) Add 3.77 g of potassium hydroxide aqueous solution (70 wt%). Water was removed under vacuum at 120° C. for 3 h. The remaining 600 g of oxyalkylene was metered in at a flow rate of 600 g / h (the mass ratio of propylene oxide to ethylene oxide was 1:3). After continuing to react for 1.5h, the temperature was raised to 140°C for another 1.5h.

[0087] 3) Add 9.24 g of 50 wt % phosphoric acid aqueous solution to remove K ions, and process to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com