Comprehensive treatment method for sulfur dioxide exhaust gas

A technology for comprehensive treatment of sulfur dioxide, which is applied in the direction of chemical instruments and methods, separation methods, halogen oxides/oxyacids, etc., can solve the problems of high sulfur dioxide content, reduce environmental impact, achieve good treatment effects, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

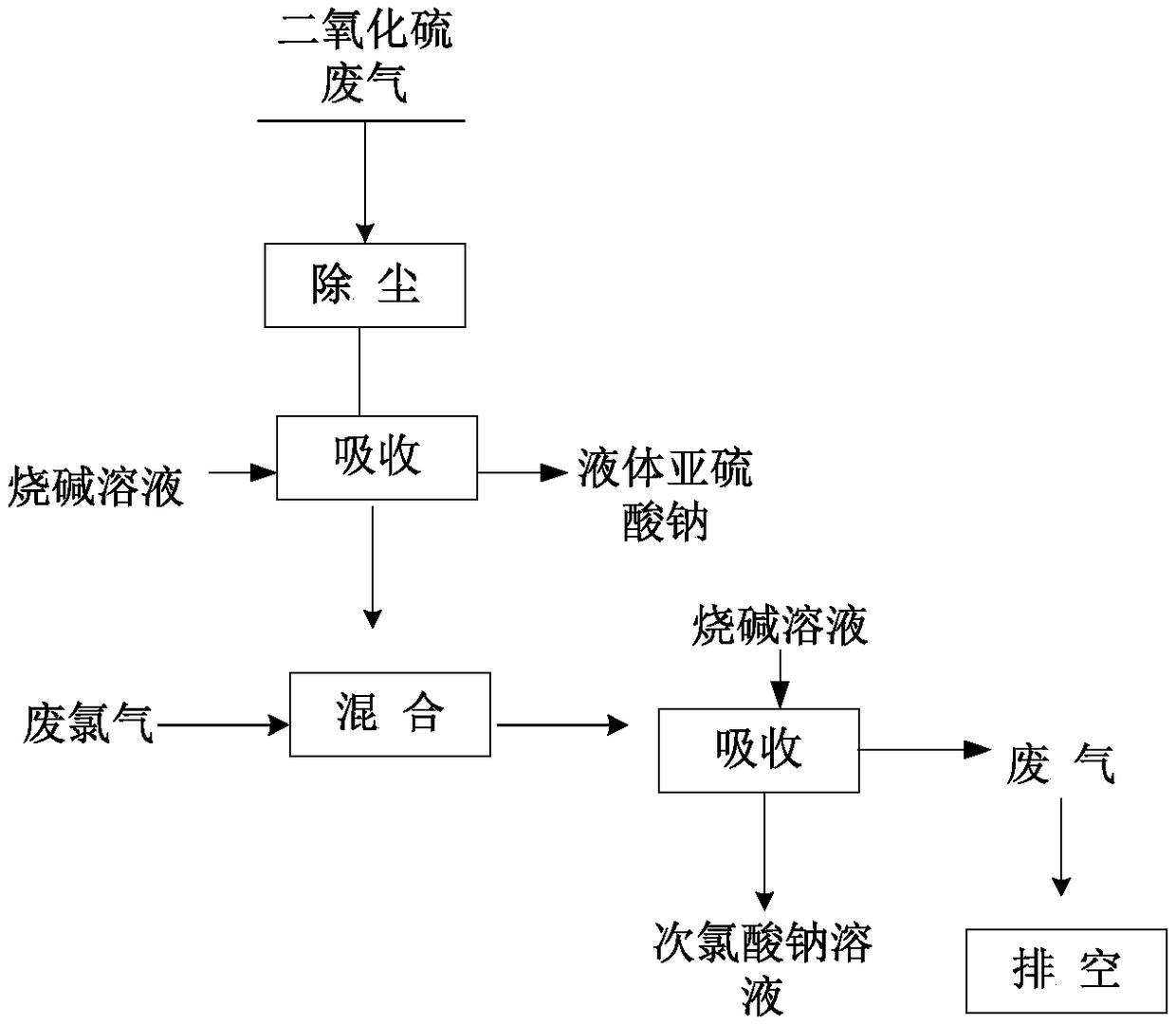

Image

Examples

Embodiment 1

[0033] The content of sulfur dioxide in the sulfur dioxide waste gas of a sulfuric acid production plant is 0.5-5%. The sulfur dioxide waste gas is treated by gravity dust removal, and the waste gas is collected by the waste gas fan. The operating pressure is -2-0KPa, and the outlet pressure of the fan is 5-20KPa.

[0034] Under the pressure condition of 0-5kpa, the absorption tower adopts a caustic soda solution with a mass concentration of 11% to absorb sulfur dioxide waste gas, controls the pH value of the absorption end point of the lye to be 10-11, and obtains a 13% sodium sulfite solution and lye with a mass concentration. Absorbed waste gas; use sodium sulfite solution directly; pass the waste gas absorbed by lye into the waste chlorine gas system, and absorb it with caustic soda solution with a mass concentration of 17% in the absorption tower under the operating conditions of -1.5 ~ -0.5kpa. The lye absorption end point is that the effective alkali is less than 1%, and...

Embodiment 2

[0036] The content of sulfur dioxide in the sulfur dioxide exhaust gas of a sulfuric acid production plant is 0.3-5%. The sulfur dioxide exhaust gas is treated by gravity dust removal, and the exhaust gas is collected by the exhaust gas fan. The operating pressure is -1.8-0KPa, and the outlet pressure of the fan is 5-20KPa. enterprise;

[0037] Under the pressure condition of 0-5kpa in the absorption tower, the caustic soda solution with a mass concentration of 15% is used to absorb sulfur dioxide waste gas, and the pH value of the absorption end point of the lye is controlled to be 9-11, so that the sodium sulfite solution and lye with a mass concentration of 15% are obtained. Absorbed waste gas; use sodium sulfite solution directly; pass the waste gas absorbed by lye into the waste chlorine gas system, and absorb it with caustic soda solution with a mass concentration of 15% in the absorption tower under the operating condition of -1.5 ~ -0.5kpa. The end point of liquid abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com