Weighing, pouring and spreading mechanism for flexible polishing pad production

A soft grinding disc and material pouring technology, applied in grinding devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of high labor intensity, low labor rate, air holes, etc., and achieve high automation and high efficiency. Intelligent control, the effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

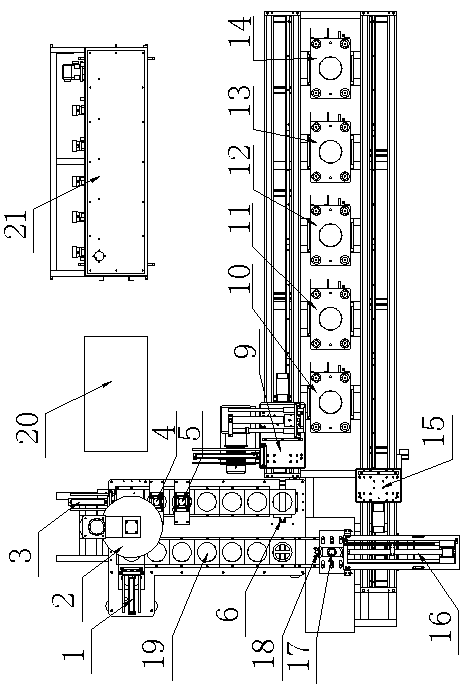

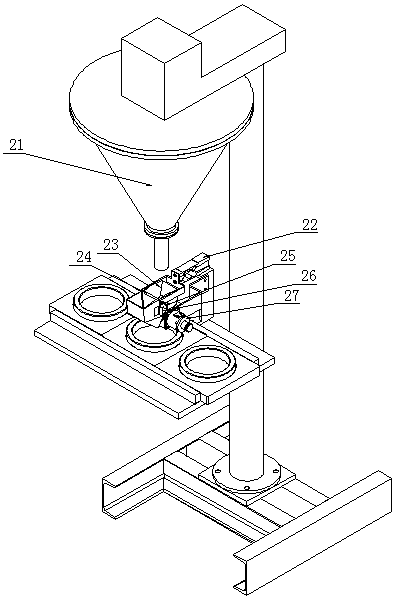

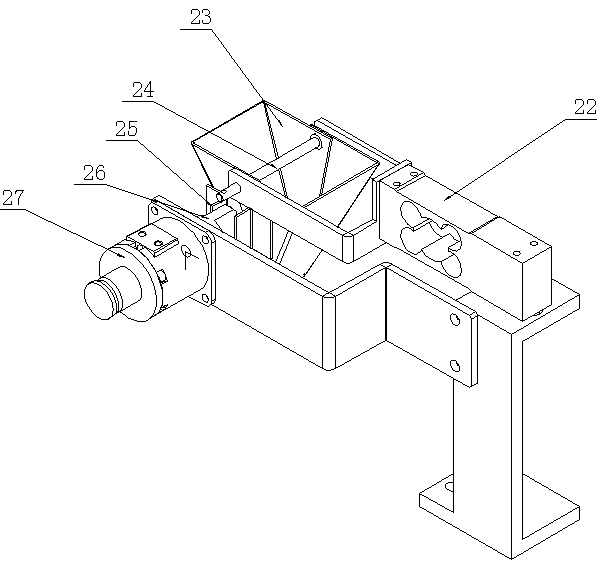

[0059] Such as Figure 1 to Figure 12 As shown, a kind of soft grinding sheet rotary production line of the present embodiment comprises a weighing and spreading platform, a feeding mechanism 9, a host mechanism, a discharging mechanism 15, a mold unloading press mechanism, and a control module 20 (the control module is used to control weighing Material stall material platform, feeding mechanism, host mechanism, discharging mechanism and unloading mold press mechanism operation) and hydraulic station 21. The weighing, unloading and spreading mechanism used in the production of soft abrasive discs enables the mold to perform a rotary streamlined operation, realizing the automatic operations of picking, weighing, spreading, transporting the mold into the press, transporting it out of the press, and unloading the mold.

[0060] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com