Numerically controlled quantitative weighing type multi-station continuous casting machine

A quantitative weighing and digital control technology, which is applied in the direction of manufacturing tools, metal processing equipment, and equipment for supplying molten metal, etc., can solve the problems of inability to weigh the amount of molten iron and large impact of workpieces, so as to improve space utilization and achieve accurate The effect of positioning and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, and it is stated here that the present invention is explained with this schematic example, but not as a limitation of the present invention.

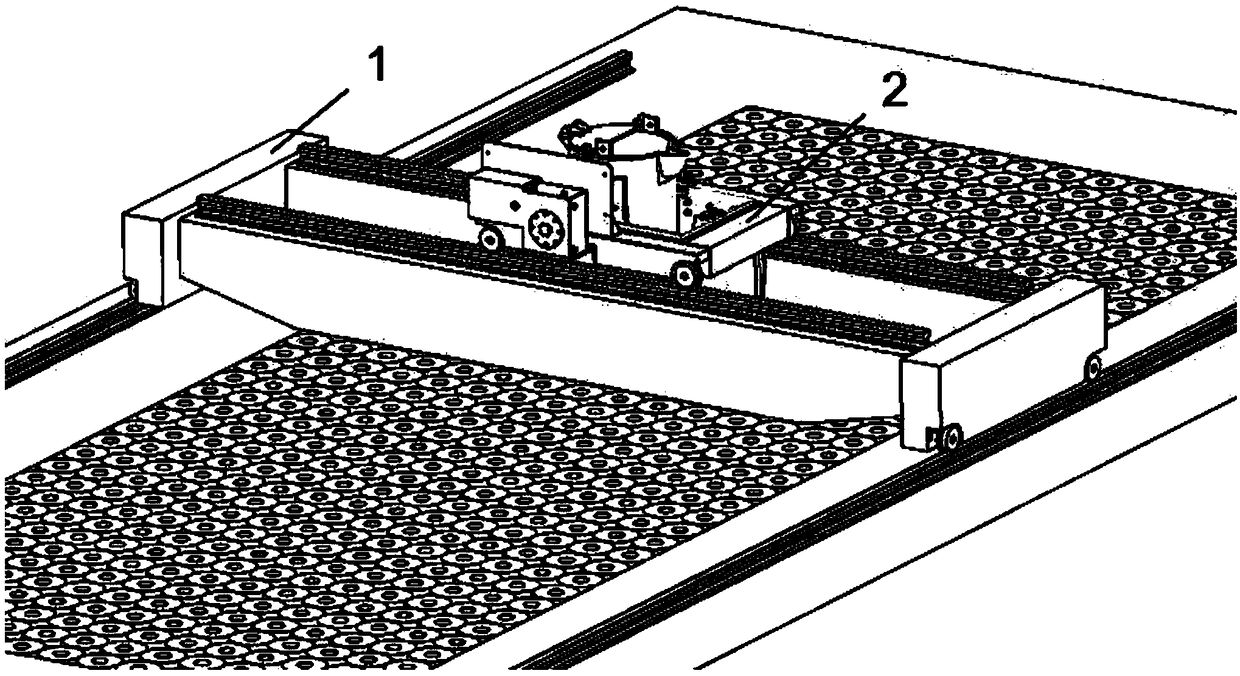

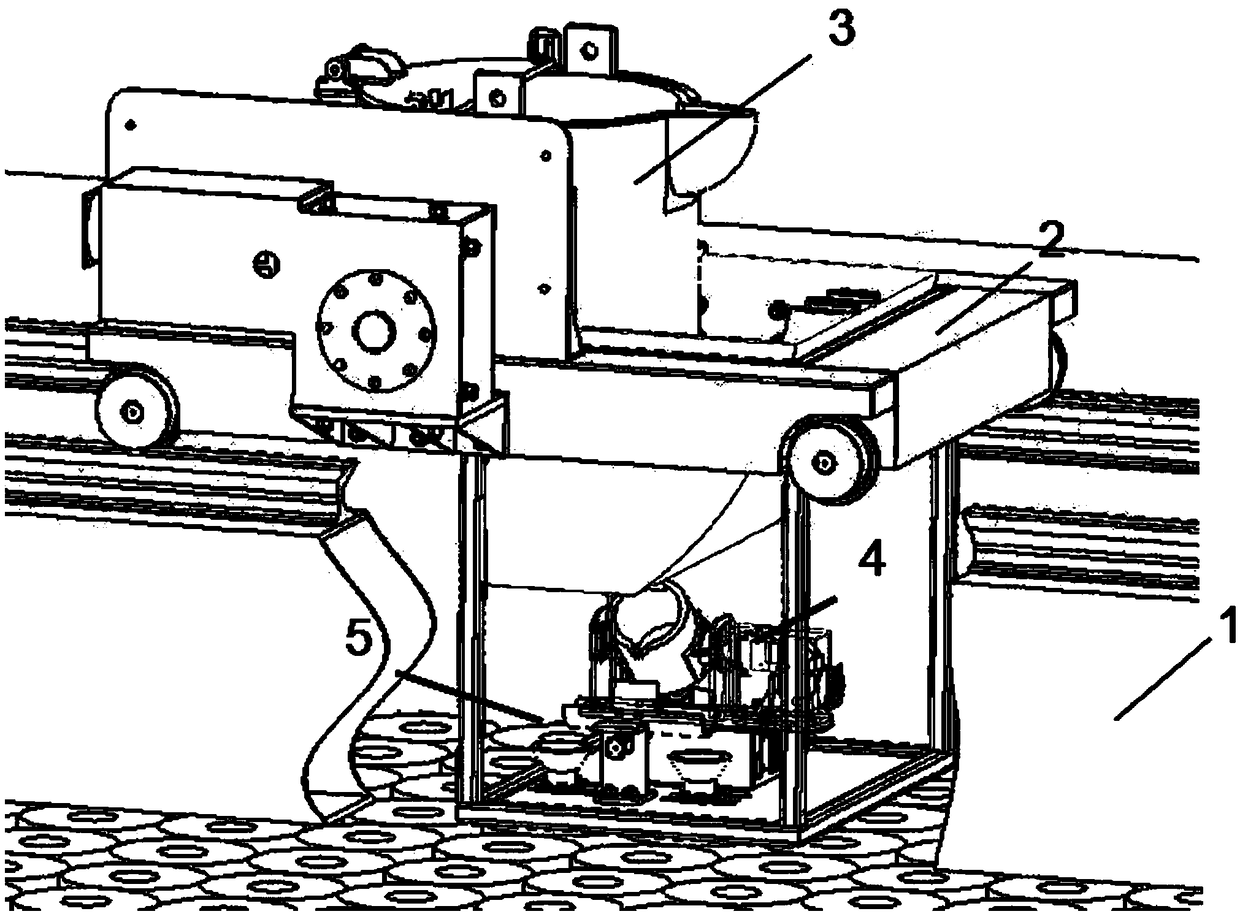

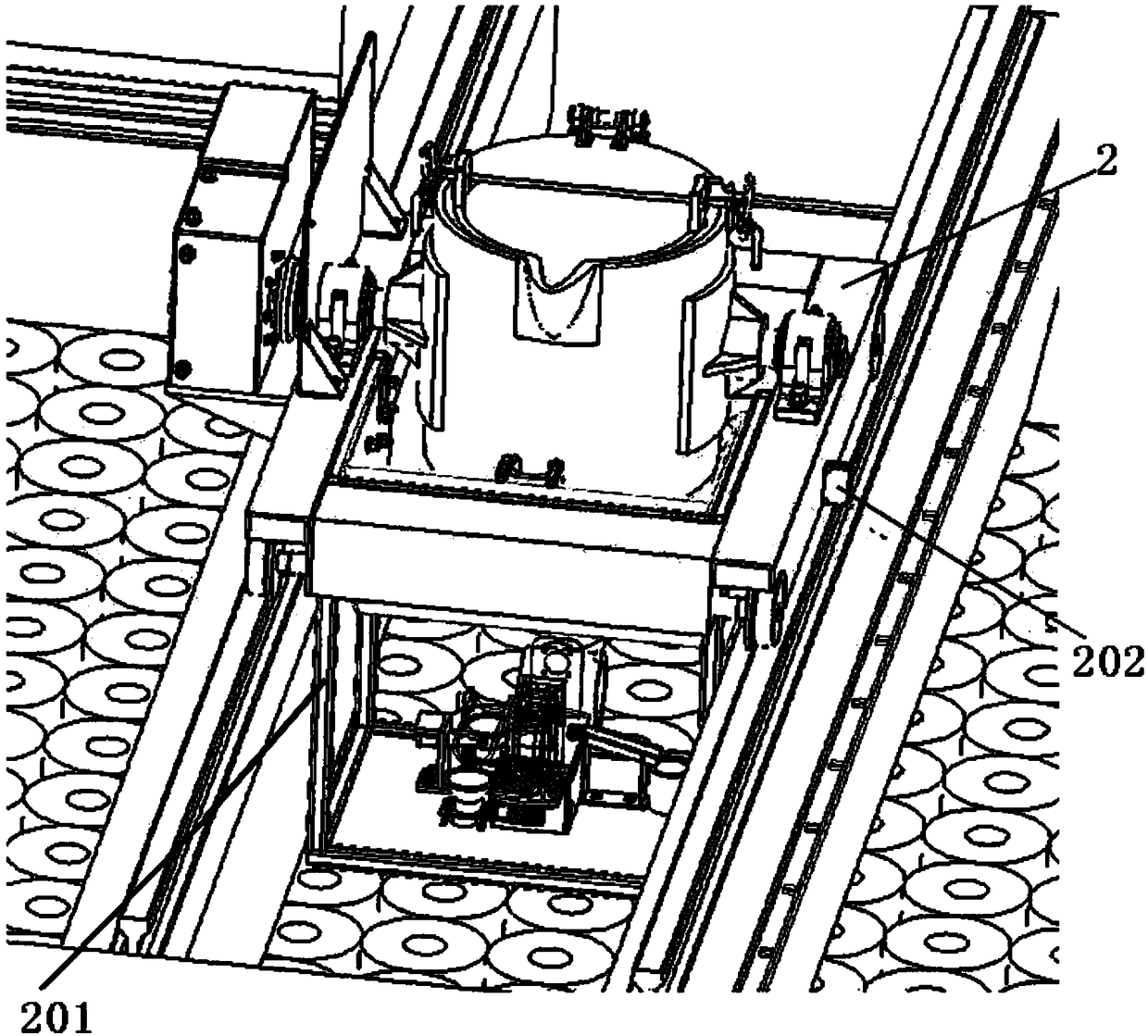

[0028] refer to figure 1 and image 3 , the digitally controlled quantitative weighing multi-station continuous pouring machine of the present invention includes a beam running module 1, a trolley running module 2, a numerically controlled pouring ladle mechanism 3, an automatic quantitative weighing mechanism 4 and a multi-station sprue system 5 The crossbeam running module 1 is set on the foundation rail and can move longitudinally along the foundation rail; the trolley running module 2 is set on the crossbeam running module 1 and can move laterally along the crossbeam running module 1, so the trolley running module 2 can realize horizontal and vertical movement move. The CNC ladle dumping mechanism 3, the automatic quantita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com