True triaxial fracturing test device

A fracturing test, true triaxial technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problems that are not conducive to layout and cannot be disassembled repeatedly, so as to achieve convenient and quick installation and disassembly, ensure sealing performance, Ease of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the drawings.

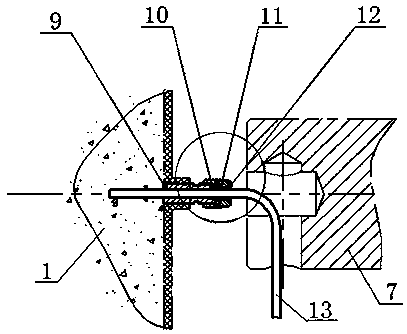

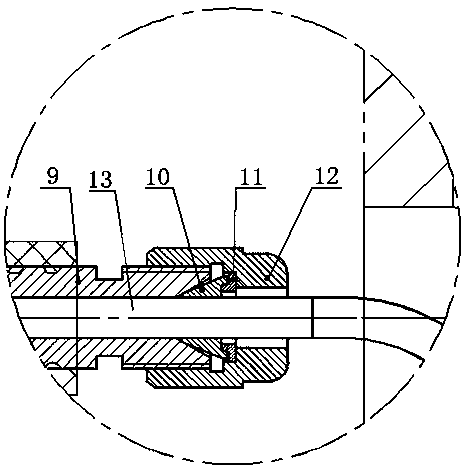

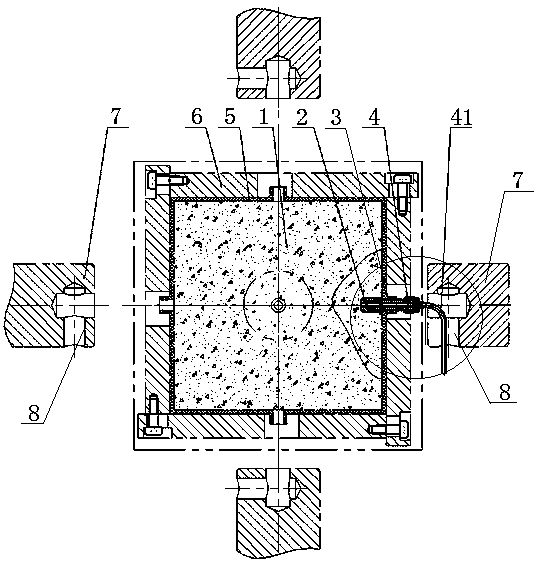

[0026] See image 3 with Figure 4 , The true triaxial fracturing test device shown includes a loading assembly, a fracturing tube, and an injection pump. The fracturing tube includes a first joint 2, an adapter tube 3, and a second joint 4 that are connected. The first joint 2 Buried in the fracturing hole of sample 1, one end of the inserted sample 1 is welded with the first fracturing pipeline 21, and the other end is provided with a sinking platform, and the sinking platform is provided with the end of the adapter pipe 3 The internal thread realizes the detachable connection of the first joint 2 and the adapter tube 3. The adapter tube 3 passes through the sealing rubber sleeve 5 of the loading assembly, and the other end is connected to the second joint 4. The second joint 4 is sheathed with a movable nut 42 which is provided with an end of the adapter tube 3 in a mating conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com