An iron and steel enterprise refined cost accounting control method based on a whole process flow

A technology of cost accounting and control methods, applied in computing, manufacturing computing systems, instruments, etc., can solve problems such as incomplete cost analysis, lagging cost information, and limited cost accounting refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0078] Related terminology and terminology:

[0079] ITEM: It is the smallest value unit that manages various production factors of the company;

[0080] ERP: Enterprise Resource Planning (Enterprise Resource Planning);

[0081] BOM Bill of Material (Bill Of Material);

[0082] PMAC: Period Moving Average Cost;

[0083] Routing: process flow.

[0084] A refined cost accounting control method for iron and steel enterprises based on the whole process flow, including:

[0085] D1. System function construction

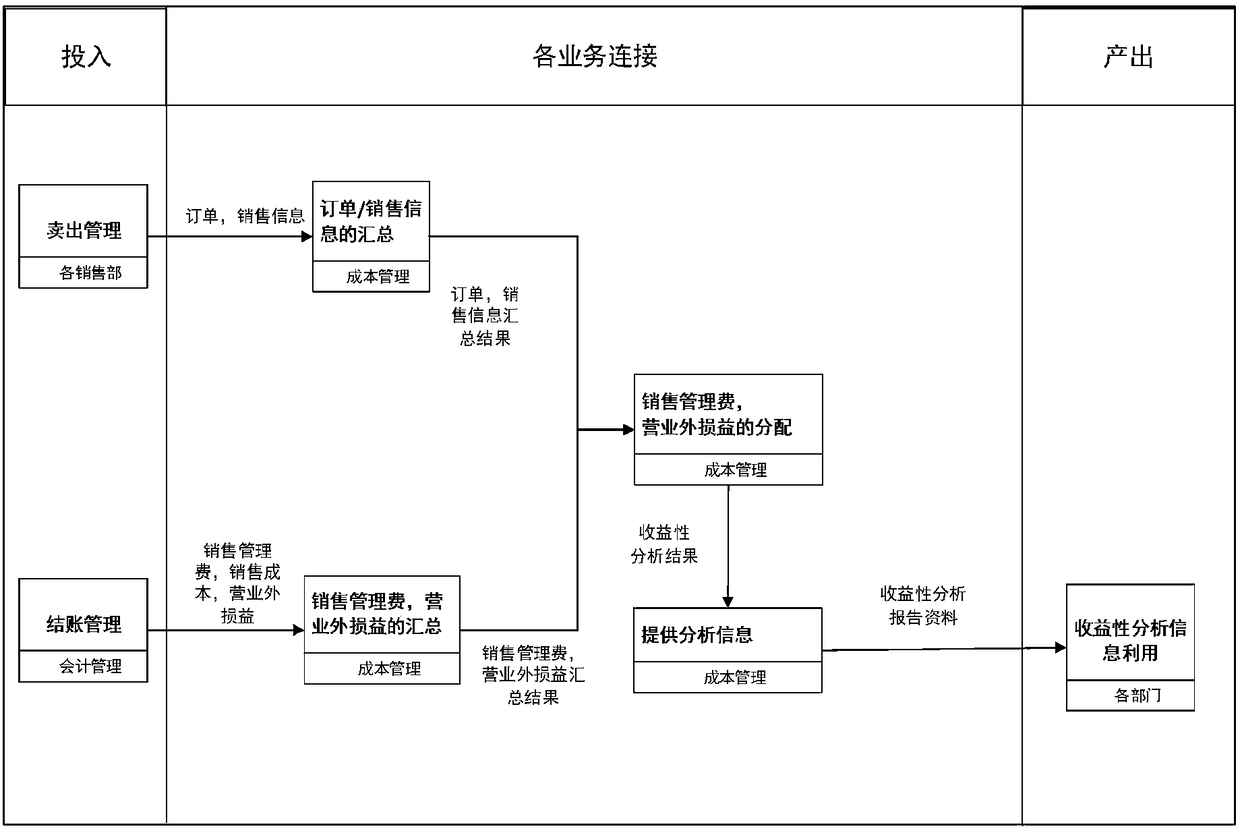

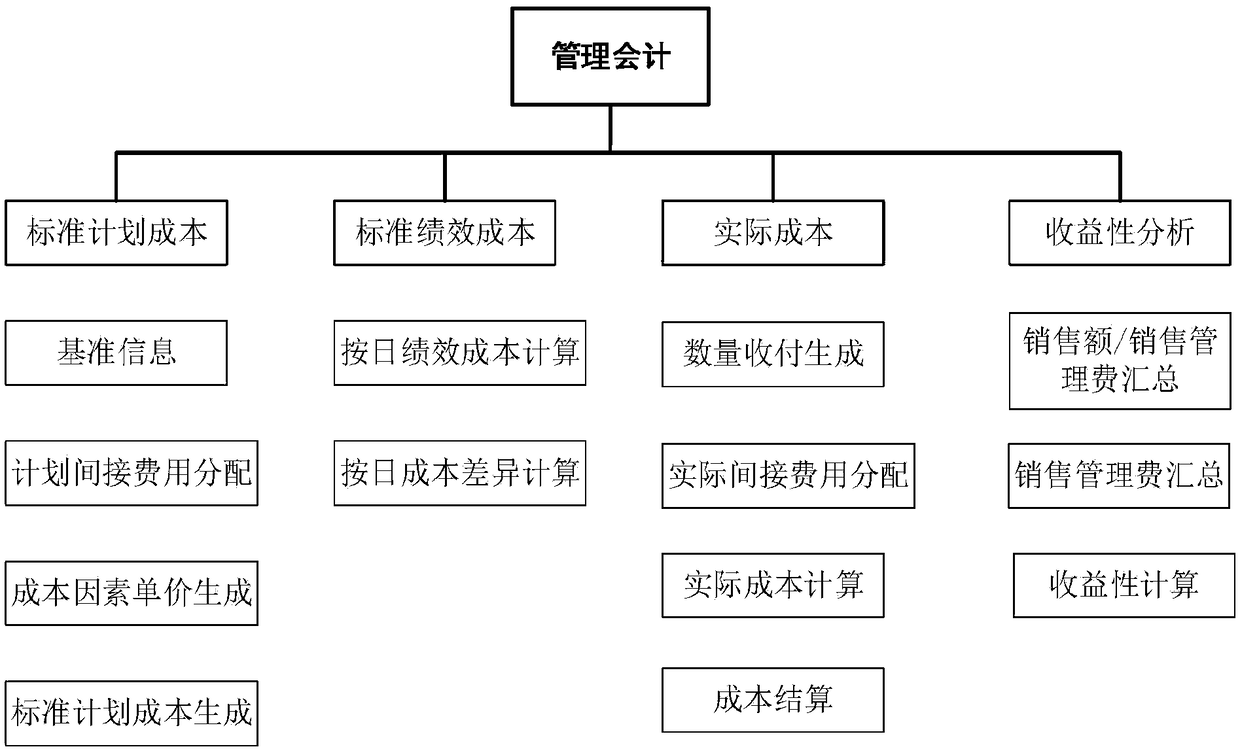

[0086] The main function of the system is management accounting, covering the following four aspects, see figure 1 :

[0087] 1.1 Standard plan cost, including benchmark information, plan overhead allocation, cost factor unit price generation, and stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com