Method for rapidly judging running mileage of battery modules in fault nickel-metal hydride battery pack

A technology for battery modules and nickel-metal hydride batteries, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of high battery activity, fast battery aging, and large workload, and achieves a simple acquisition method and reduces battery status. Analysis and selection of team work, the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for quickly judging the operating mileage of the battery module in the faulty Ni-MH battery pack is carried out according to the following steps:

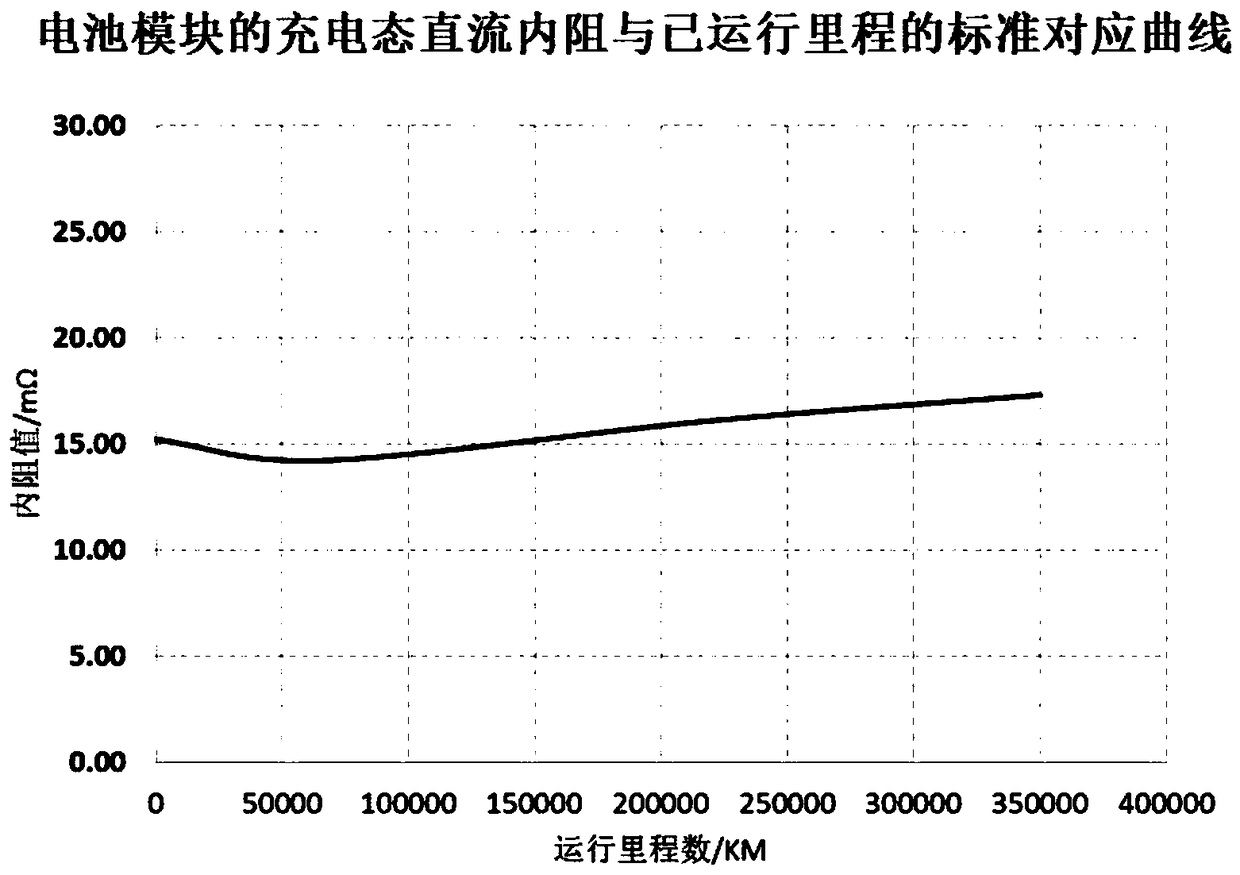

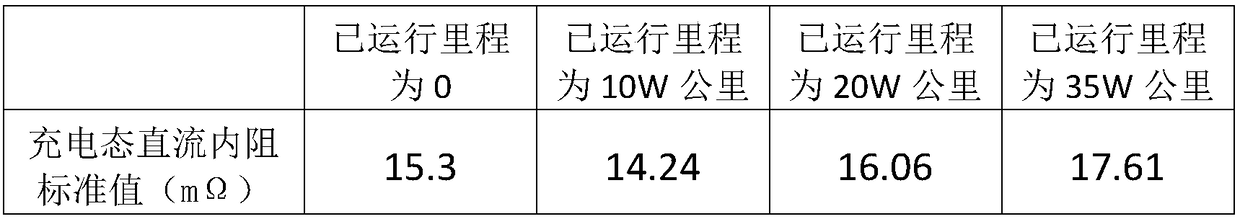

[0022] ⅠTake one or more normal Ni-MH battery packs of the same type from N kinds of Ni-MH battery packs with different operating mileages. The operating mileage of the Ni-MH battery packs can be selected from 0 to L, and L is the rated total operating mileage of the battery pack. N is a natural number above 4, and the sample selection of the running mileage of the Ni-MH battery pack includes 0 and L, and several normal battery modules are respectively taken from the Ni-MH battery pack with the same running mileage, and the running mileage of the same running mileage is respectively measured. The charging state DC internal resistance of several battery modules is taken as the standard value of the charging state DC internal resistance of the running mileage battery module, and the charging state DC internal resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com