Two-phase flow fluid sampler

A fluid sampler and phase flow technology, applied in the field of samplers, can solve the problems of lack of strain detection ability, inconvenient detection, influence of fluid detection, etc., and achieve the effect of increasing practicability and functional effect, and increasing contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

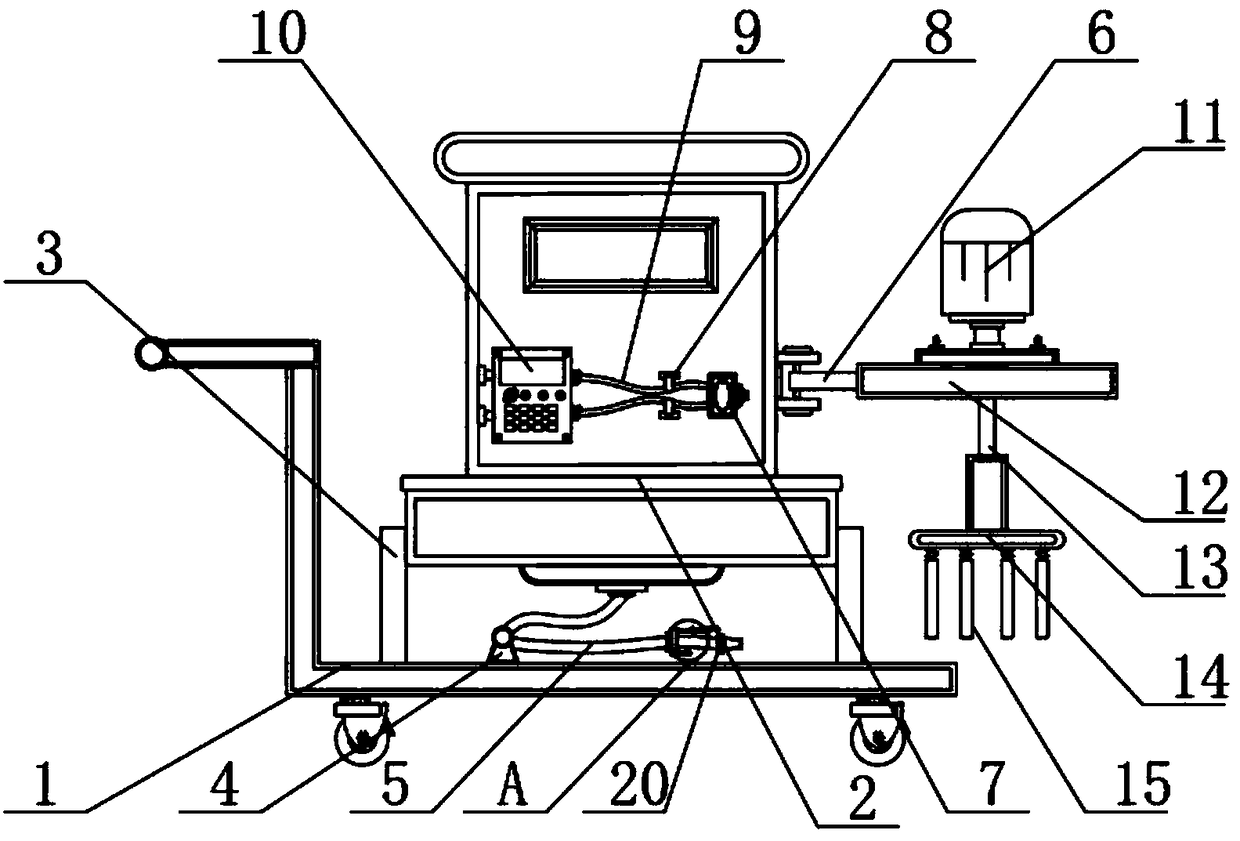

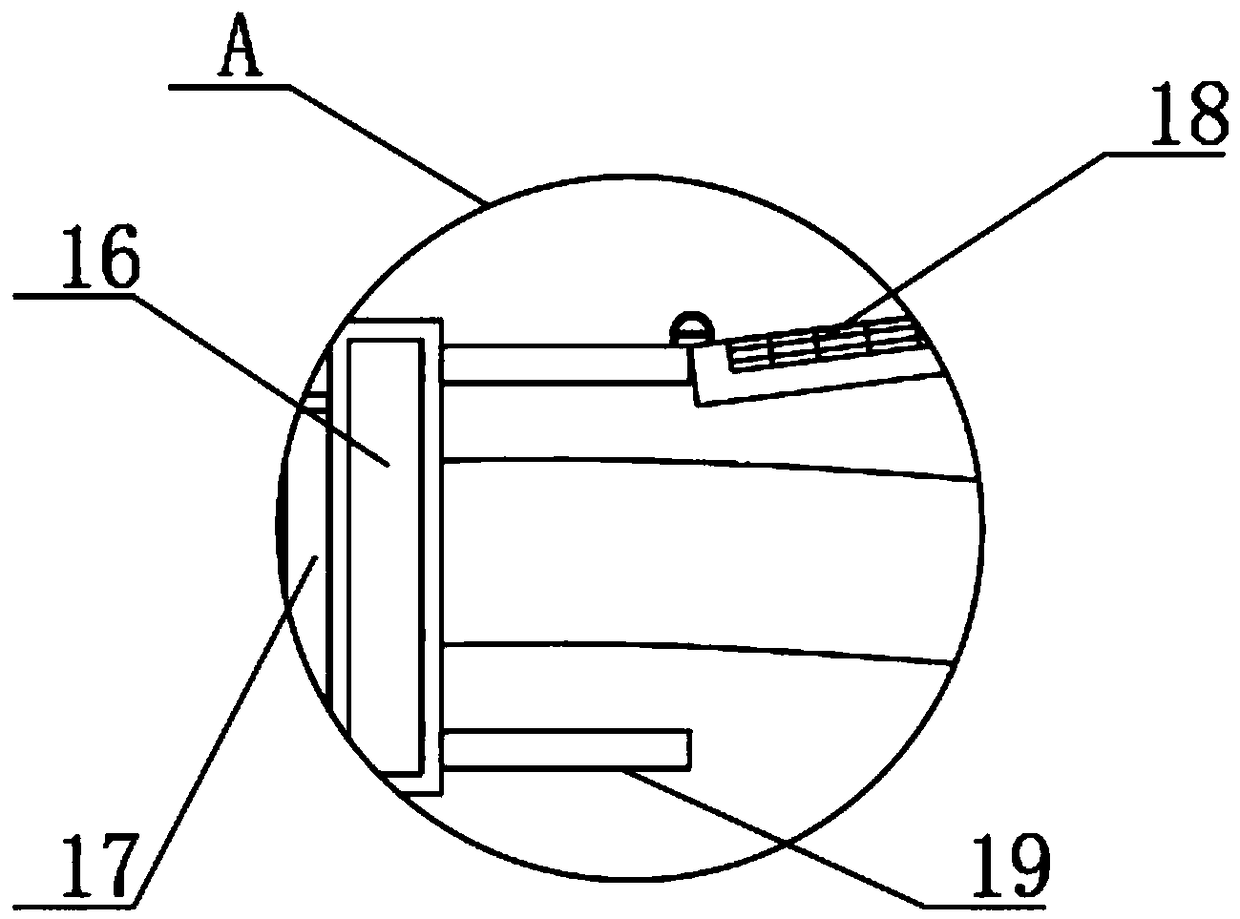

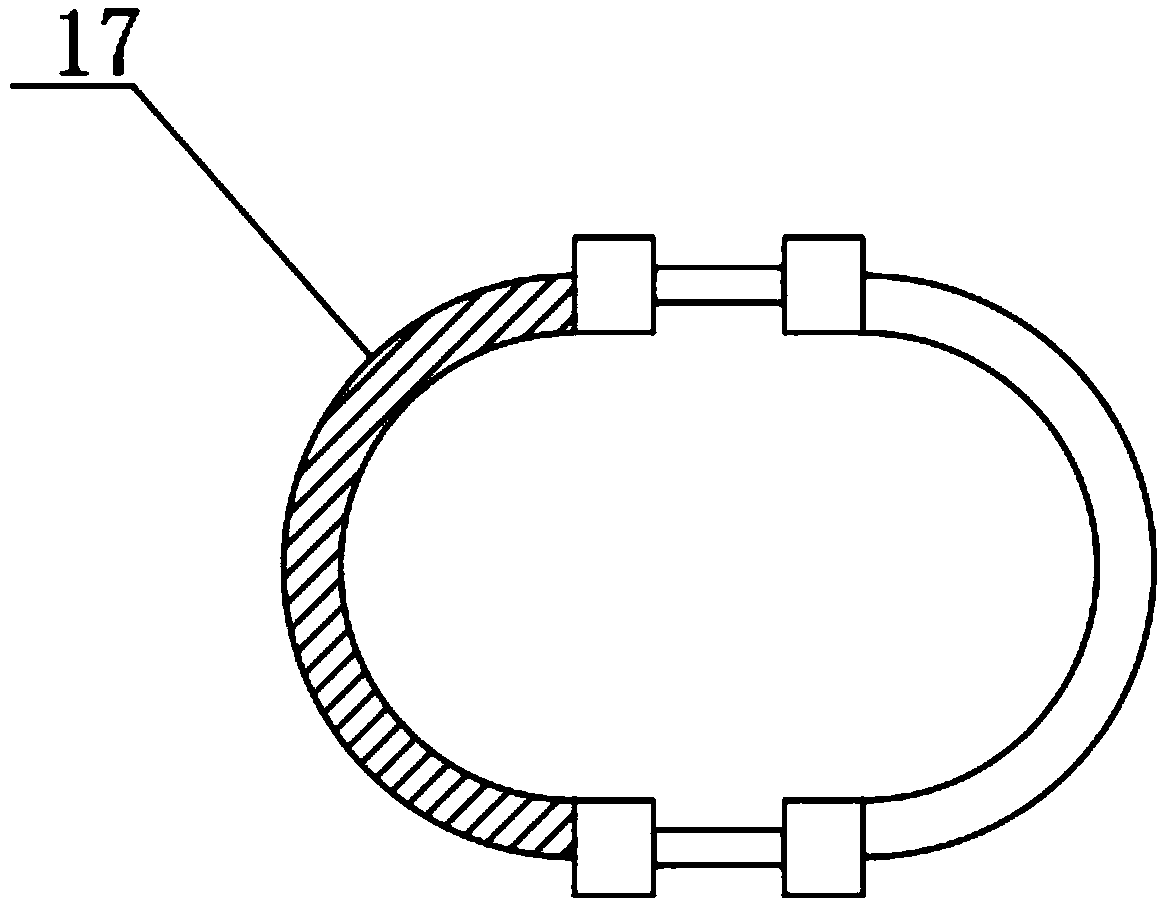

[0022] see Figure 1-5 , the present invention provides the following technical solutions: a two-phase flow fluid sampler, including an outer shell 2, a bottom plate 1 is arranged below the outer shell 2, an connecting rod 3 is arranged between the bottom plate 1 and the outer shell 2, and the bottom plate 1 is connected through the The rod 3 is fixedly connected with the outer shell 2, the upper surface of the bottom plate 1 is fixedly connected with the air pump 4 by screws, the inside of the air pump 4 is connected with a collection pipe 5, and one end of the collection pipe 5 is screwed with a suction head 20, and the collection pipe 5 There is a cover block 16 fitted on the outside of the cover block 16, and a fixed block 17 is engaged on one side surface of the cover block 16. The side of the cover block 16 different from the fixed block 17 is welded with a limit block 19, and one side of the limit block 19 is hinged by a hinge. The net cover 18 solves the problem that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com