Drop test machine and method for adjusting drop attitude

A drop test and attitude technology, applied in the field of drop test, can solve the problems of troublesome attitude adjustment of the test product, poor drop test effect, and inability to realize angle control, etc., and achieve the requirements of improving the grasping range, avoiding inaccuracy, and ensuring accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

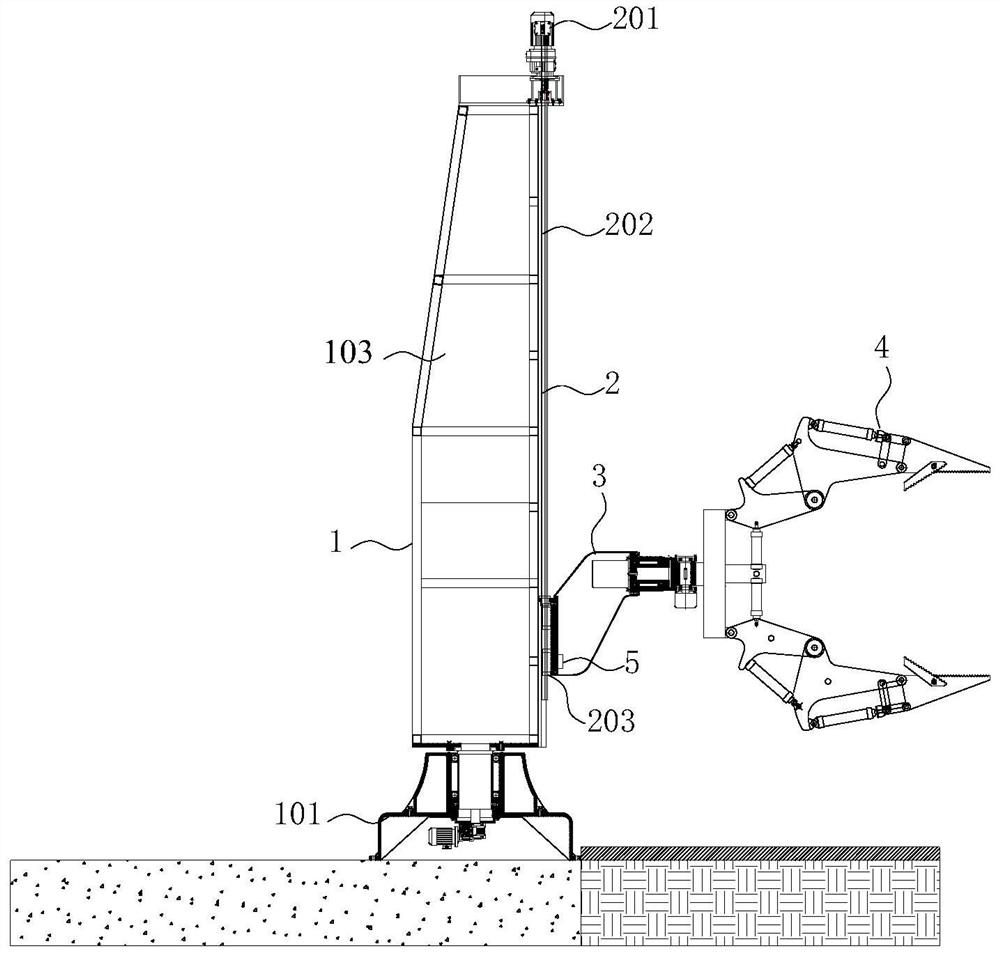

[0059] See attached figure 1 And attached figure 2 , the drop tester of the present invention comprises:

[0060] A drop frame 1, the drop frame 1 performs a rotary motion relative to its own rotary shaft 102;

[0061] A lifting mechanism 2 arranged vertically on one side of the drop frame 1;

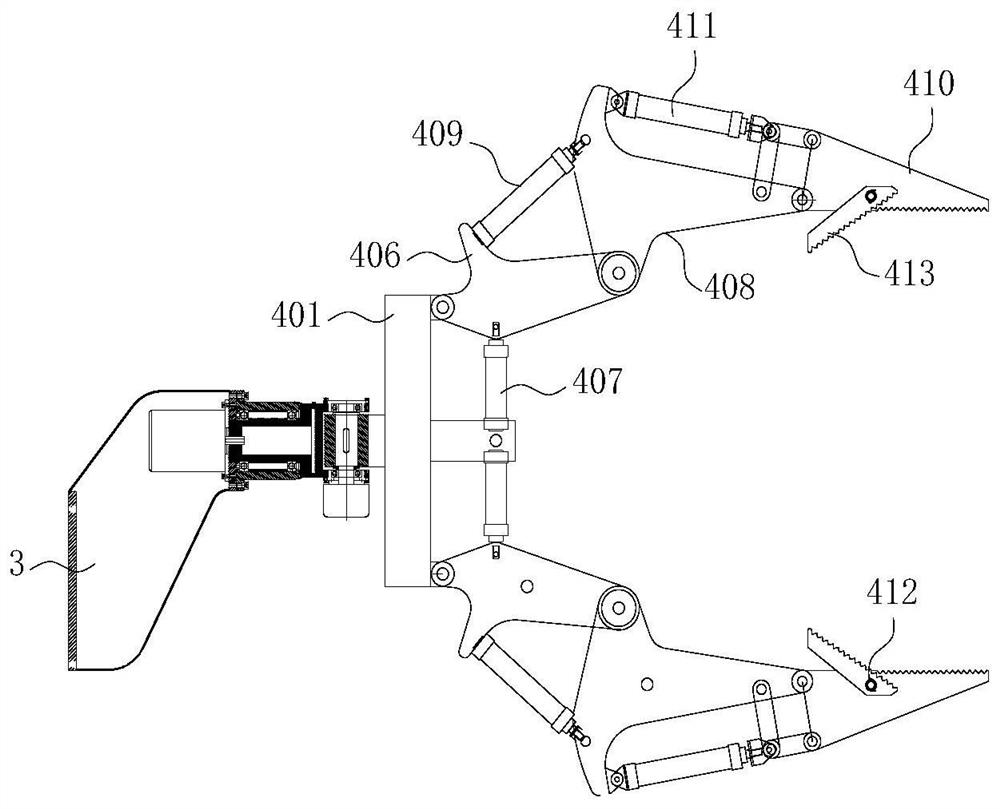

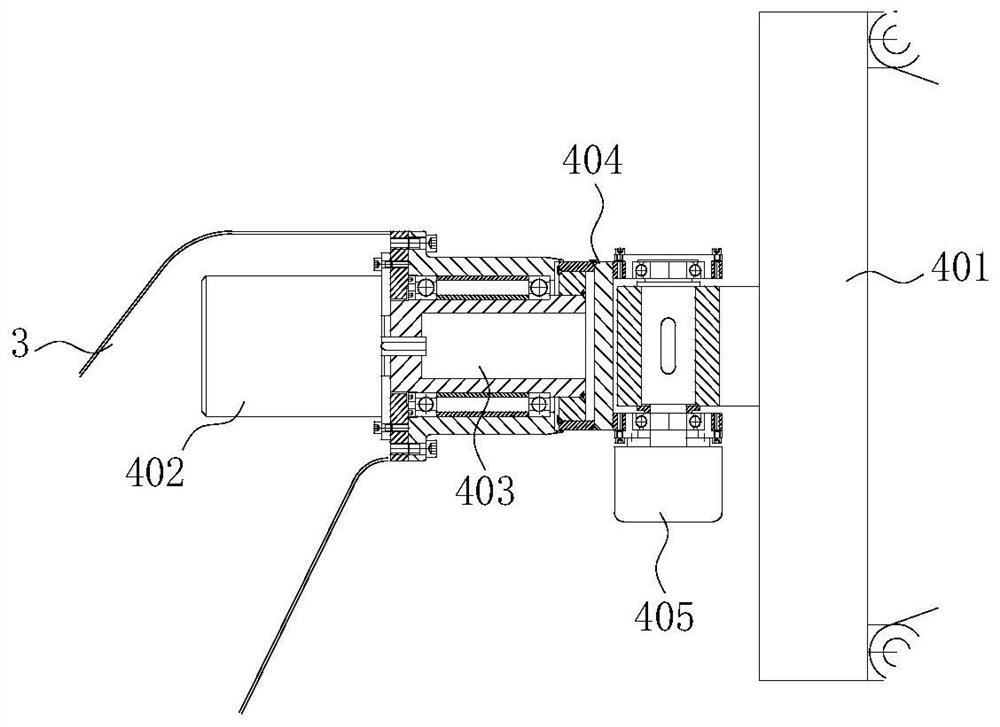

[0062] And the manipulator 4 fixedly connected by the crank arm 3 and the lifting mechanism 2, the manipulator 4 includes a fixed plate 401, a posture adjustment unit connected between an end surface of the fixed plate 401 and the crank arm 3 and symmetrically arranged on the The two groups of grasping units on the other end surface of the fixed plate 401; the posture adjustment unit drives the manipulator 4 to rotate in the horizontal direction and the vertical direction as a whole, and the relative opening and closing movement of the two groups of grasping uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com