Aviation-engine-blade-surface data evaluation method based on model

An aero-engine and evaluation method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the measurement results cannot reflect the real situation of the parts, the evaluation method of profile measurement data is unreasonable, and the measurement reproducibility is poor, so as to improve the detection technology and detection. efficiency, improving product quality and testing efficiency, and the effect of stable operation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0034] A kind of model-based evaluation method of aeroengine blade profile data of the present invention comprises the following steps:

[0035] 1) The profile of the blade profile to be evaluated is the line profile without reference, and the line profile is fitted with the theoretical profile before the evaluation;

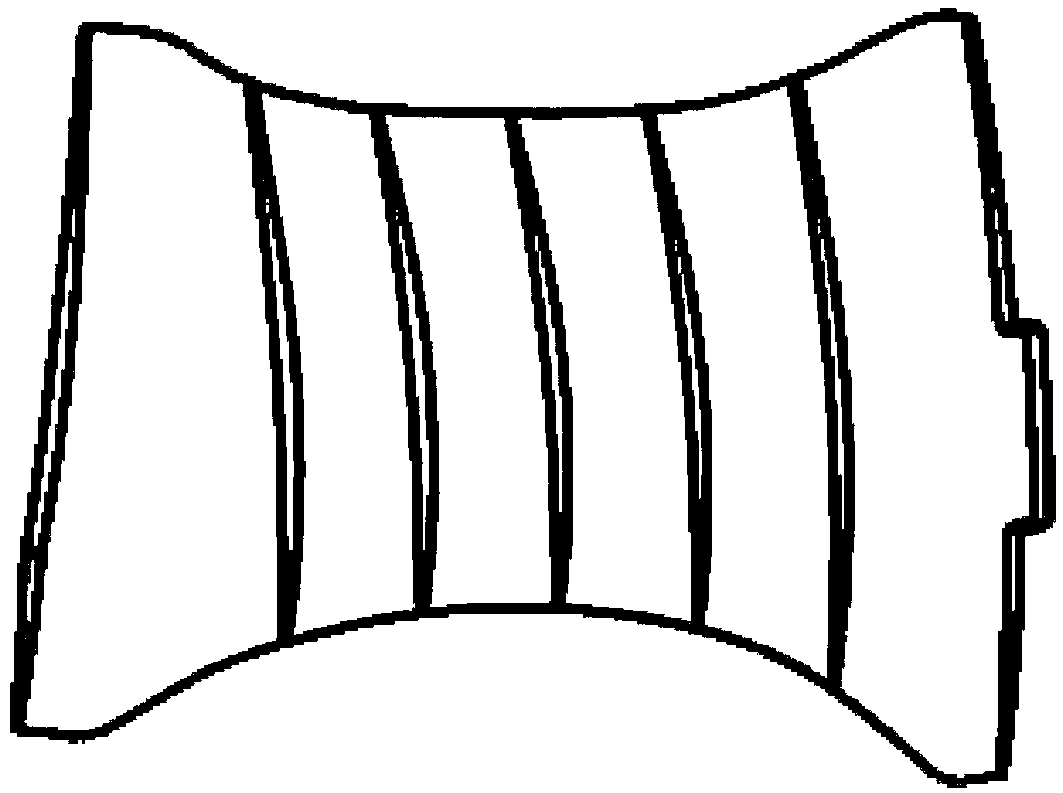

[0036] 2) Thicken the existing blade profile design model, and generate a new blade profile through the blade curve group as a theoretical model for profile evaluation;

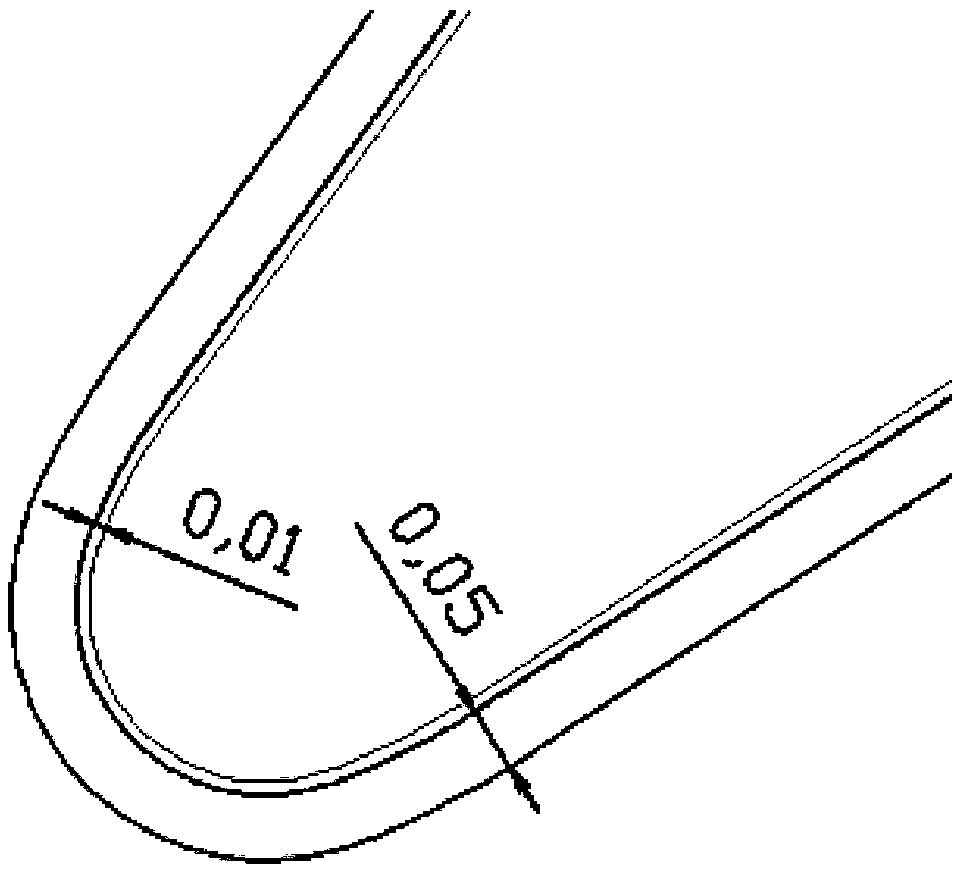

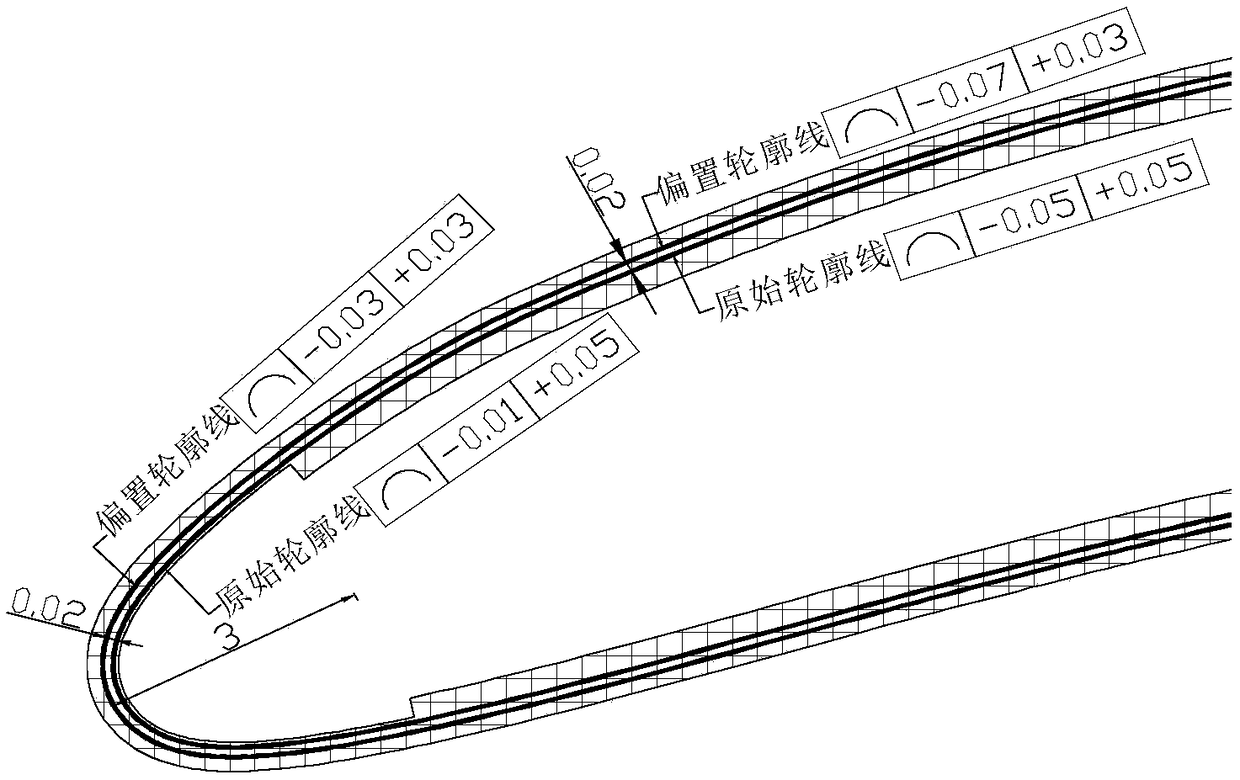

[0037] 3) In the case of ensuring that the position of the tolerance zone of the blade profile remains unchanged, change the upper and lower limit values of the tolerance zone, change the original tolerance +0.05mm~-0.01mm, and set the new tolerance to +0.03mm~-0.03 mm, make the contour tolerance zone a symmetrical tolerance zone;

[0038] 4) Use the theoretical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com