A Surface Wetness Sensor

A sensor and wetting technology, applied in the field of sample surface wetness measurement devices, can solve the problems of easy consumption of electrode materials, difficult sensor miniaturization, and distortion of measurement results, so as to achieve good reproducibility of measurement results, avoid material consumption, and true measurement results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

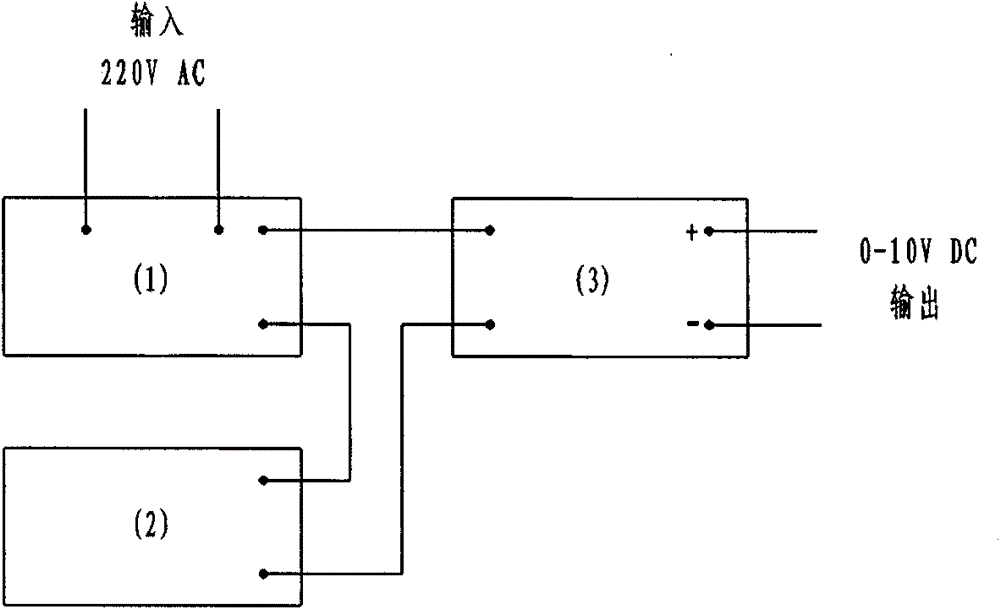

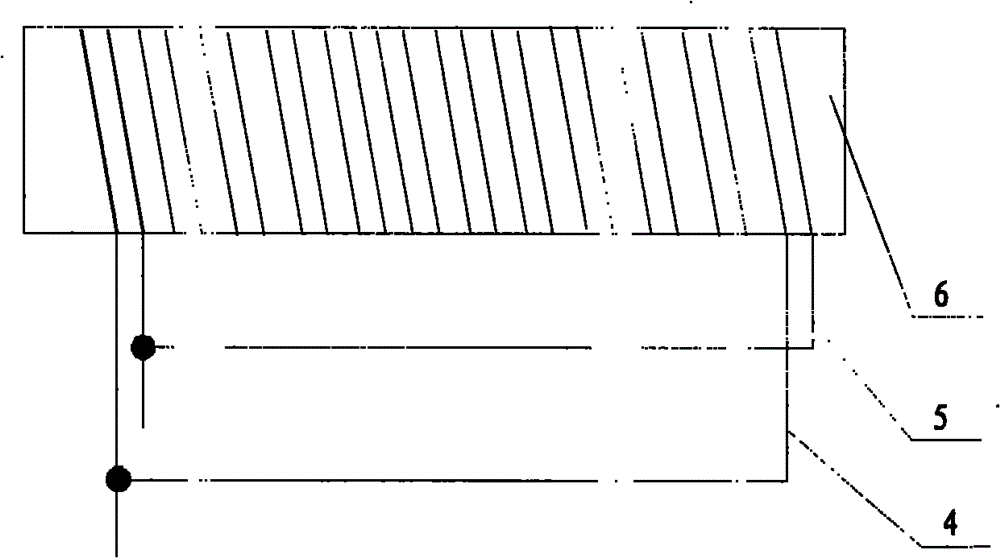

[0028] Embodiment 1: as figure 1 , image 3 As shown, a surface wetting sensor is characterized in that: it includes a signal source 1, a surface wetting sensing unit 2 and a detection output unit 3;

[0029] The signal source 1 generates an electrical signal and provides it to the surface wetting sensing unit 2; the surface wetting sensing unit 2 detects the surface wetting information and converts it into a corresponding current signal; the detection output unit 3 converts the current signal of the surface wetting sensing unit 2 into voltage signal and output.

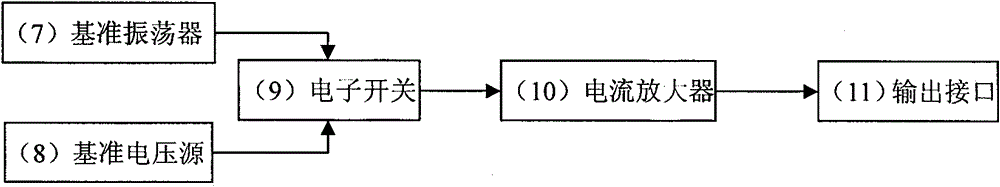

[0030] The signal source 1 includes a reference oscillator 7, a reference voltage source 8, an electronic switch 9, a current amplifier 10 and an output interface 11;

[0031] The reference oscillator 7 generates accurate square waves, and different frequencies are selected by jumpers; the reference voltage source 8 generates a stable reference voltage, and the size of the reference voltage is changed through a var...

Embodiment 2

[0043] Embodiment 2: as Figure 5 As shown, the difference from Embodiment 1 is that the insulator 6 is provided with a number of micro-holes with equal spacing, and gold wires pass through the micro-holes to form parallel winding metal wires.

Embodiment 3

[0044] Embodiment 3: as Figure 6 As shown, different from Embodiments 1 and 2, the insulator 6 is only provided with microgrooves at both ends. The gold wires are wound in the grooves to form a structure parallel to each other.

[0045] The above-mentioned metal wires may be precious metal wires, or other metal wires with strong corrosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com