Volute of centrifugal fan

A centrifugal fan and volute technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of increased flow loss, neglect of non-uniformity and flow field, large left and right size, etc., to improve static pressure , improve user experience, improve the effect of fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

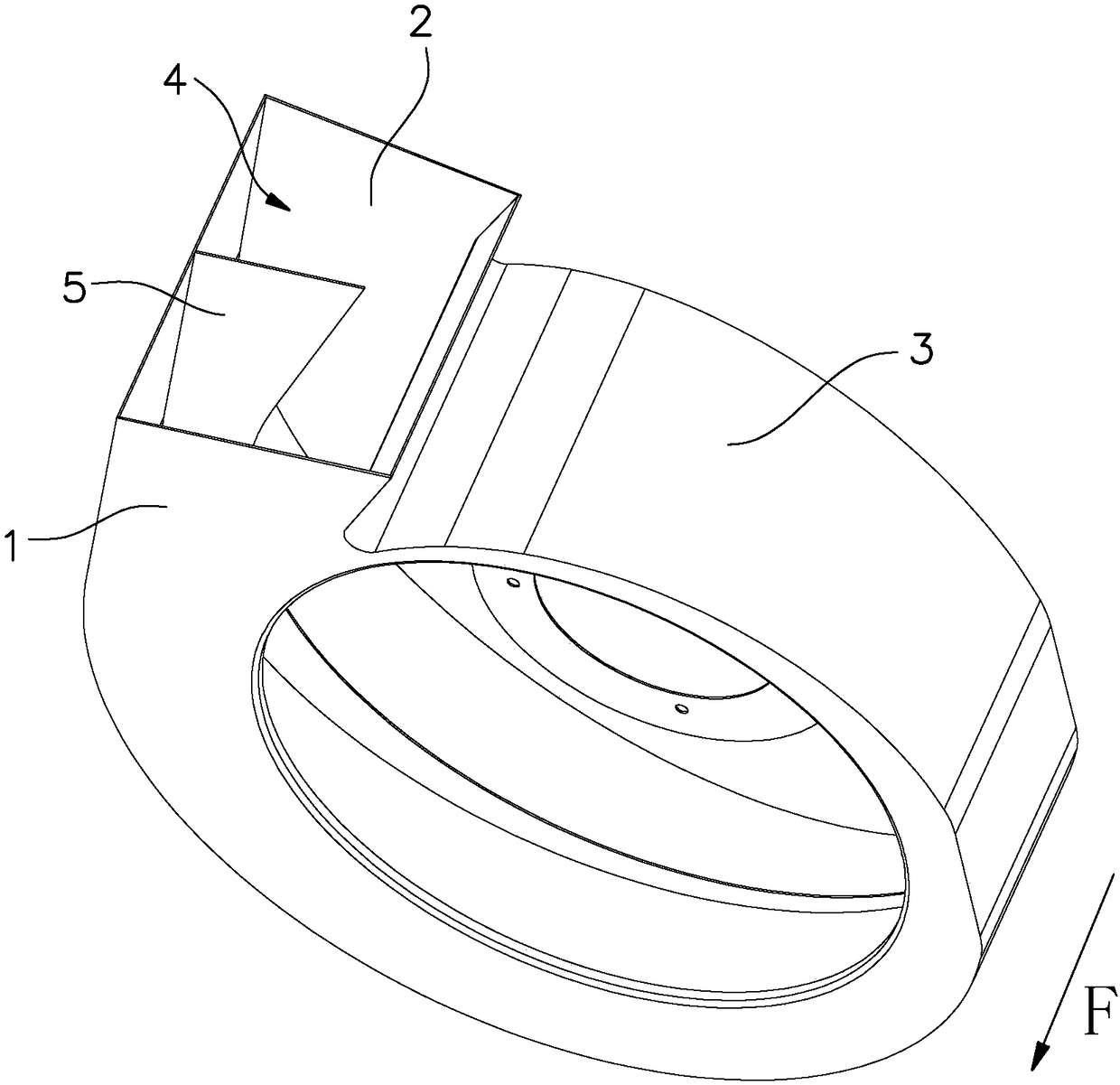

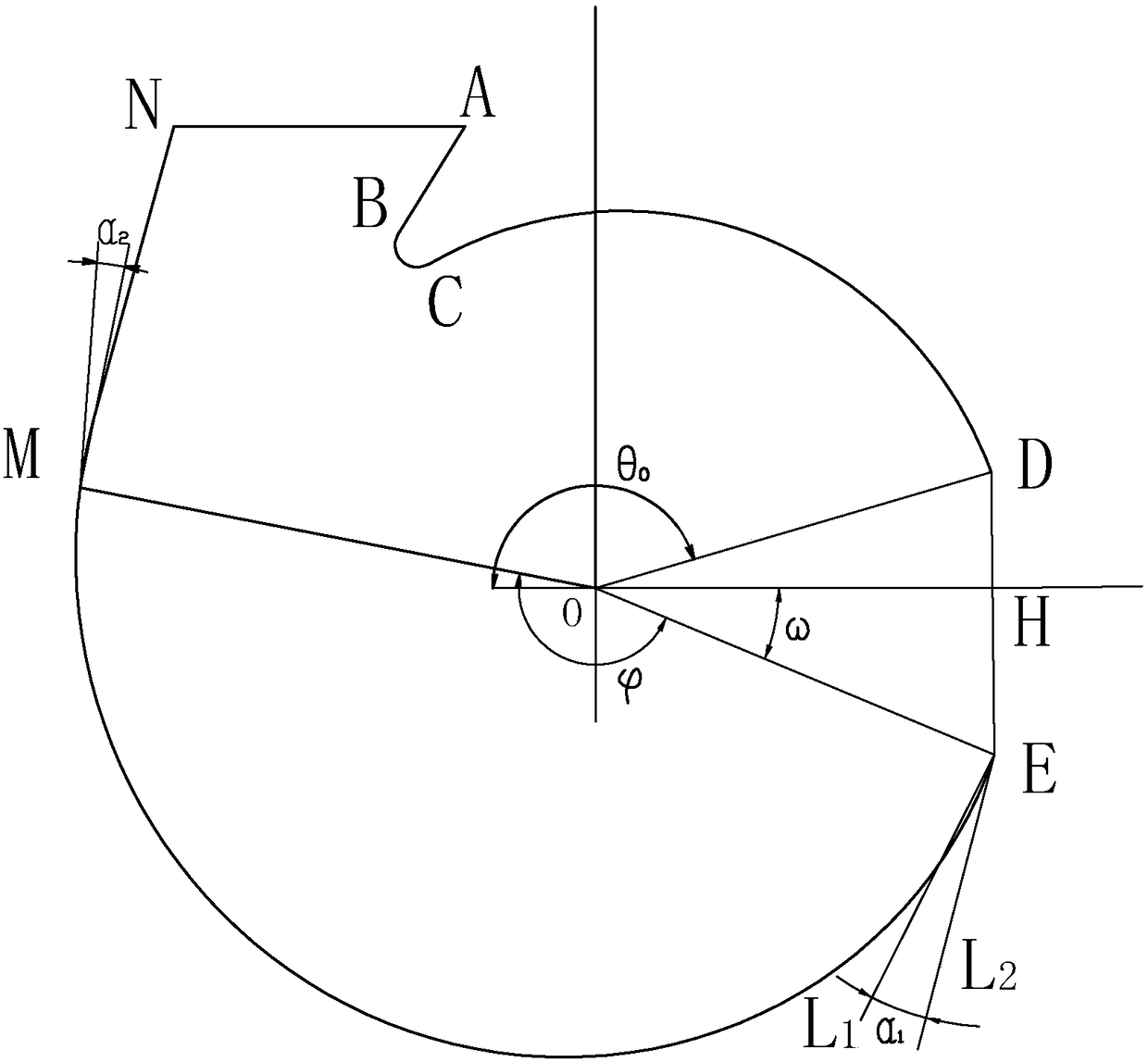

[0021] Such as figure 1 and figure 2 shown in figure 1 The direction indicated by the middle arrow F is forward. The centrifugal fan volute in this embodiment includes a front cover 1, a rear cover 2 and a ring wall 3 connected between the front cover and the rear cover. The volute profile of the volute It includes the starting line AC located at one end of the molded line and the ending line MN located at the other end of the molded line. The starting line AC includes a straight line AB adjacent to the fan outlet 4 and a curve BC corresponding to the volute tongue, and the ending line MN is adjacent to the fan outlet. The tuyere 4, the volute-shaped line also includes a first helix CD, an edge DE and a second helix EM sequentially connected between the start line AC and the end line MN. Point D of the first spiral CD and point E of the second spiral EM do not coincide with each other, point D is above the horizontal line OH passing through the center point O of the volute,...

Embodiment 2

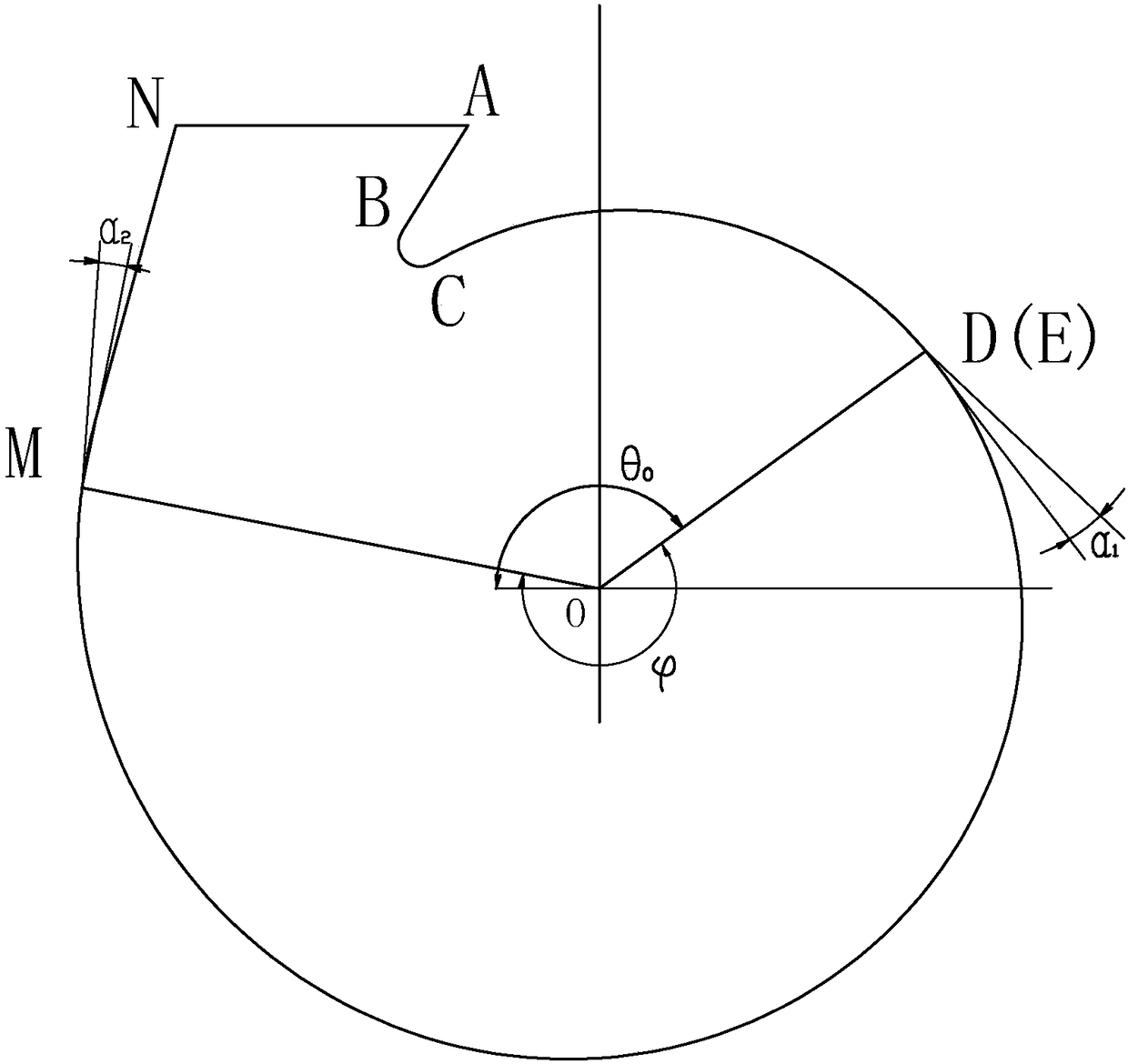

[0027] Such as image 3 As shown, point D of the first helix CD and point E of the second helix EM coincide with each other in the volute shape of the present embodiment, that is, the first helix CD and the second helix EM are directly connected.

[0028] Furthermore, the polar radius R of the first helix CD CD defined as: Among them, R 2 is the outer diameter of the impeller, t is the design clearance between the outer circumference of the impeller and the top of the volute tongue, and t / R 2 ∈[0.01,0.15], expansion angle α∈[3°,8°], θ 0 is the starting angle of point D of the first helix CD, and θ 0 ∈[60°, 180°], θ is the polar coordinate angle variable of any point on the first helix CD, and the polar radius R of the second helix EM EM defined as: Among them, R 2 is the outer diameter of the impeller, t is the design clearance between the outer circumference of the impeller and the top of the volute tongue, and t / R 2 ∈[0.01,0.15], variable expansion angle alpha 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com