Quick changing method and system of expressway overline bridge

A technology for expressways and flyovers, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as long-term operation over expressways, negative social effects, potential safety hazards, and high requirements for safety and environmental protection control. To achieve the effect of shortening the duration of traffic closure, low traffic impact, and reducing the requirements of construction organization and coordination and construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

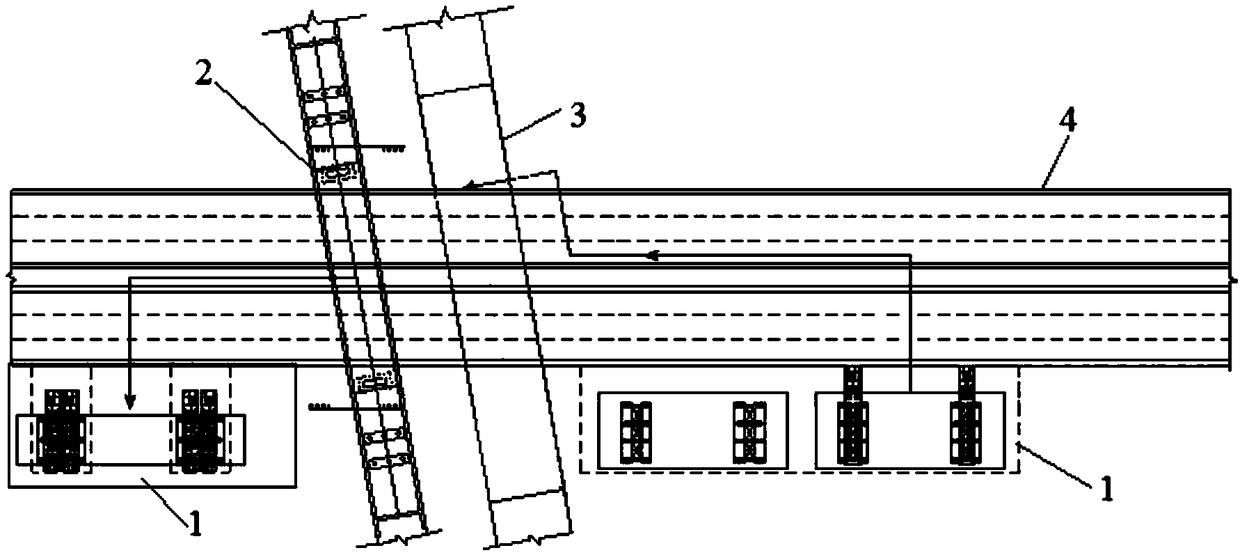

Image

Examples

Embodiment 1

[0119] 1. Construction preparation: near the overpass to be demolished and rebuilt, site preparation is carried out at the roadbeds on both sides of the expressway to be widened. One side is the site for the beams after the original bridge was demolished, and the other side is the site for the new bridge body; The field can also be on the same side. Based on the principle of setting up the roadside site near the existing overpass: arrange in a long strip along the direction of the road, try to use the area with the smallest sum of subgrade and excavation and filling that needs to be widened, and the required land area is determined by the scale of the bridge, not less than The bearing capacity of the foundation is 80kPa, the overall ground flatness is good, and the slope difference of each path is small.

[0120] 2. Rapid and integral construction and installation of new flyovers or flyover groups across the line: complete the installation of supporting beams and spliced bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com