Dyeing method utilizing natural pigment of cudrania tricuspidata

A technology of natural pigments and wood, applied in the field of natural pigment dyeing, can solve problems such as no reports, and achieve the effects of improving various fastnesses, overcoming fastness defects, and having broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

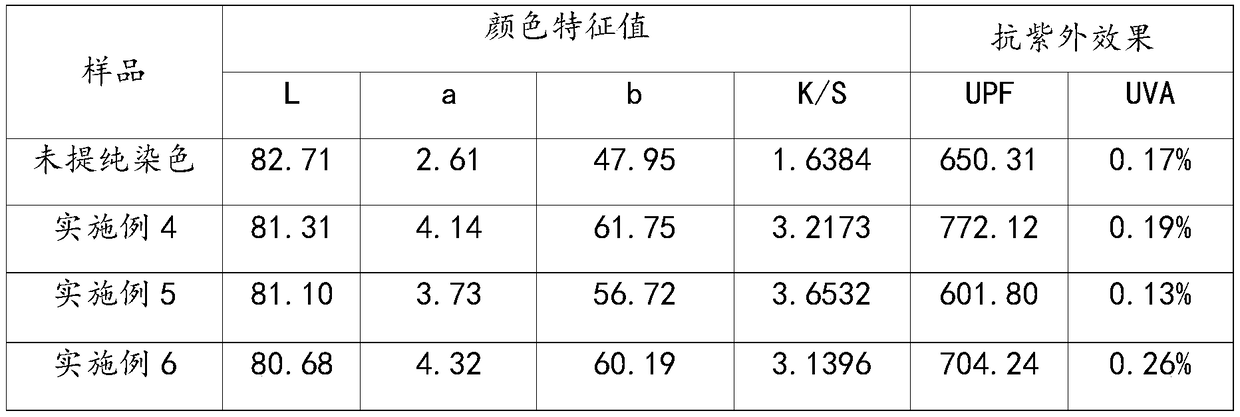

Examples

Embodiment 1

[0018] The amount of chitosan is 0.5% of the weight of the cotton fabric, the bath ratio is 1:10, the pH of the chitosan solution is adjusted to 5 with acetic acid solution, and it is put into cotton fabric for treatment, and the solution is gradually heated to 50 at a heating rate of 1 °C / min. ℃, insulation treatment 30min, obtain modified cotton-cotton fabric; Then the modified cotton-cotton fabric is put into the dyeing solution of Zhemu, the weight of the natural pigment of Zhemu in the dyeing solution is 0.2% to cotton fabric, and the liquor ratio during dyeing is 1: 20. The pH of the solution is 7, and the temperature is gradually raised to 60°C at a heating rate of 1°C / min. After heat preservation and dyeing for 30 minutes, it is washed with deionized water and used for later use; the dyed cotton fabric is post-mordant treated with metal ions, and the mordant is sulfuric acid Aluminum potassium, the dosage is 1% of the weight of the cotton fabric, the bath ratio of the p...

Embodiment 2

[0020] The dosage of chitosan is 2% to the weight of cotton fabric, the bath ratio is 1:30, adjust the pH of chitosan solution to 6 with acetic acid solution, put it into cotton fabric for treatment, and gradually heat up the solution to 60°C at a heating rate of 1°C / min. ℃, insulation treatment 40min, obtain modified cotton-cotton fabric; Then the modified cotton-cotton fabric is put into the dyeing solution of Zhemu, the weight of the natural pigment of Zhemu in the dyeing solution is 3% to the cotton fabric, and the liquor ratio during dyeing is 1: 10. The pH of the solution is 9, and the temperature is gradually raised to 70°C at a heating rate of 1°C / min. After heat preservation and dyeing for 50 minutes, it is washed with deionized water for later use; the dyed cotton fabric is post-mordant treated with metal ions, wherein the mordant is sulfuric acid Aluminum potassium, the dosage is 2% of the weight of cotton fabric, the bath ratio of the post-media treatment is 1:30, t...

Embodiment 3

[0022] The amount of chitosan is 4% of the weight of the cotton fabric, the bath ratio is 1:50, the pH of the chitosan solution is adjusted to 4 with acetic acid solution, and it is put into cotton fabric for treatment. ℃, insulation treatment 60min, obtain modified cotton-cotton fabric; Then the modified cotton-cotton fabric is put into the dyeing solution of Zhemu, the weight of the natural pigment of Zhemu in the dyeing solution is 5% to cotton fabric, and the bath ratio during dyeing is 1: 30, the pH of the solution is 5, and the temperature is gradually raised to 80°C at a heating rate of 1°C / min. After heat preservation and dyeing for 60 minutes, it is washed with deionized water for later use; the dyed cotton fabric is post-mordant treated with metal ions, and the mordant is sulfuric acid Aluminum potassium, the dosage is 1% of the weight of the cotton fabric, the bath ratio of post-media treatment is 1:20, the temperature is gradually raised to 60°C at a heating rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com