Antibacterial aloe fiber fabric and preparation method thereof

A technology of aloe vera fiber and fabric, applied in the field of textile fabrics, can solve problems such as insufficient elasticity, insufficient strength of plant fibers, skin irritation, etc., and achieve the effects of improving antibacterial durability, good moisture absorption and air permeability, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of antibacterial aloe fiber fabric:

[0028] (1) 75kg aloe fiber, 10kg yew fiber, 5kg squeezed silk are broken into 400 mesh fiber particles;

[0029] (2) the fiber particle in step 1 and 3kg polyethylene glycol 400, 0.01kg nano-silver antibacterial agent, 0.02kg active auxiliary agent, after mixing and stirring, feed into twin-screw extruder, make spinning melt;

[0030] (3) Add 3kg titanium dioxide, 1kg nanometer calcium carbonate, 0.3kg tea polyphenols, stir evenly, obtain the modified spinning melt;

[0031] (4) melt-spinning the modified spinning melt to obtain spinning fibers;

[0032] (5) The spun fibers are washed, bleached, oiled, dried, and spun into fabrics.

[0033] Preparation of coagent: Add 15g of hydroxymethylcellulose into deionized water, raise the temperature to 50°C and stir for 20min, then add 15g of salicylic acid and 0.1g of tetraethyl titanate, heat to reflux state, keep stirring for 2h, Then add 2g epoxidized soybean oil and 1g pa...

Embodiment 2

[0036] Preparation of antibacterial aloe fiber fabric:

[0037] (1) 80kg aloe fiber, 10kg yew fiber, 6kg pressed silk are broken into 400 mesh fiber particles;

[0038] (2) the fiber particles in step 1 and 3kg polyethylene glycol 400, 0.02kg nano-silver antibacterial agent, 0.02kg active auxiliary agent are fed into the twin-screw extruder after mixing and stirring, and the spinning melt is made;

[0039] (3) Add 3kg titanium dioxide, 2kg nanometer calcium carbonate, 0.4kg tea polyphenols, stir evenly, obtain the modified spinning melt;

[0040] (4) melt-spinning the modified spinning melt to obtain spinning fibers;

[0041] (5) The spun fibers are washed, bleached, oiled, dried, and spun into fabrics.

[0042] Preparation of coagent: Add 15g of hydroxymethylcellulose into deionized water, raise the temperature to 50°C and stir for 20min, then add 15g of salicylic acid and 0.1g of tetraethyl titanate, heat to reflux state, keep stirring for 2h, Then add 2g epoxidized soybe...

Embodiment 3

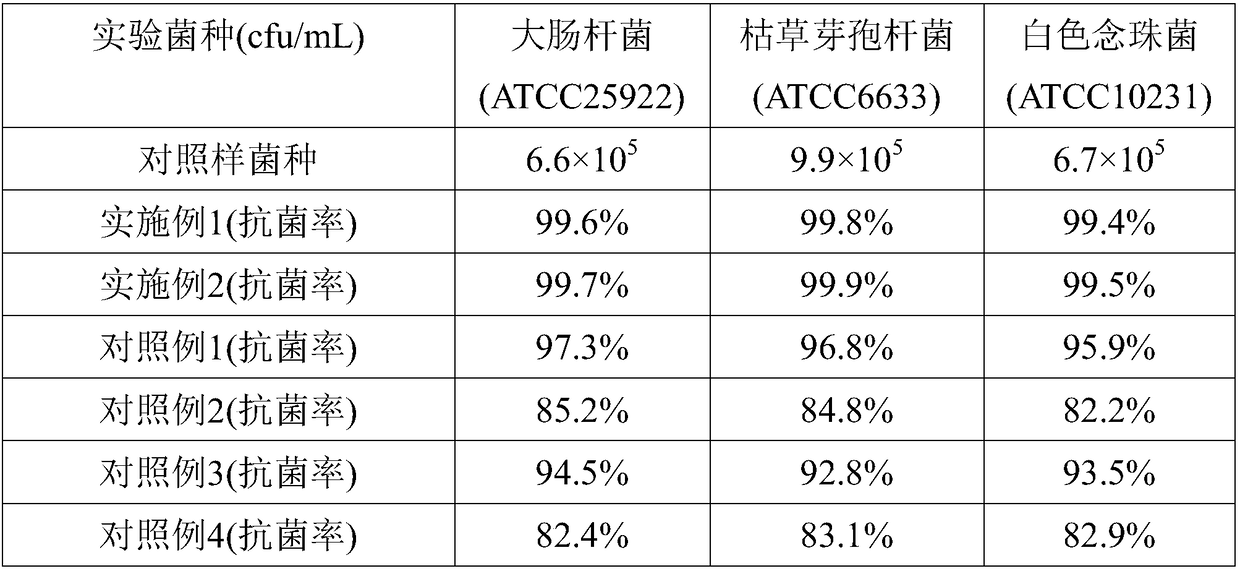

[0079] Based on Example 1, set the comparative example 1 that does not add epoxidized soybean oil and paraffin oil, the comparative example 2 that does not add coagent, the comparative example 3 that does not add castor oil, do not modify the nano silver antibacterial agent Comparative example 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com