Film tearing device for adhesive tape sticking machine

A film device and glue strip machine technology, which is applied in the directions of transportation and packaging, sending objects, and thin material processing, etc., can solve the problems of high labor intensity, high operator dependence, and low efficiency, and achieve a high degree of automation and tear film The effect of good effect and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

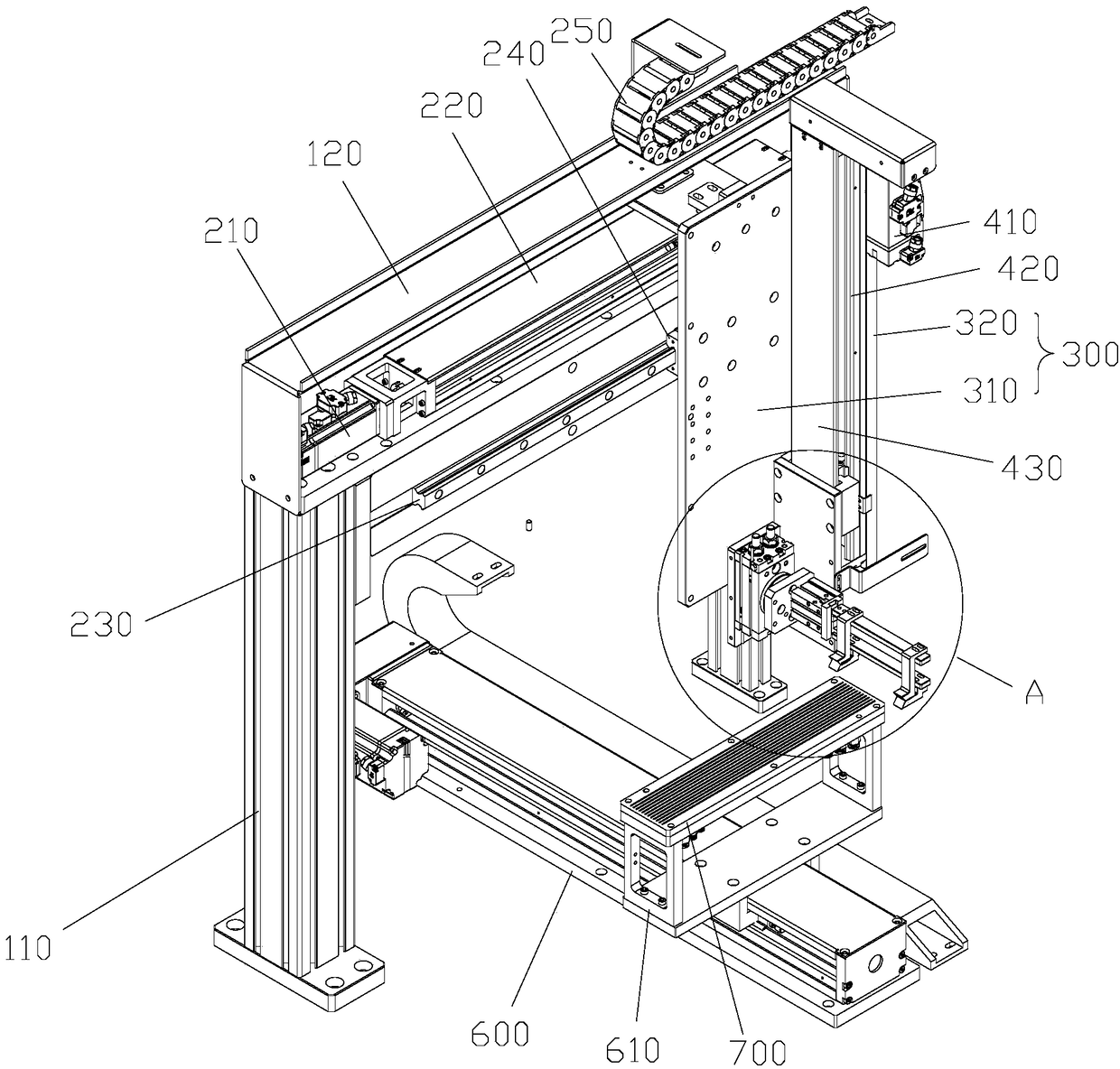

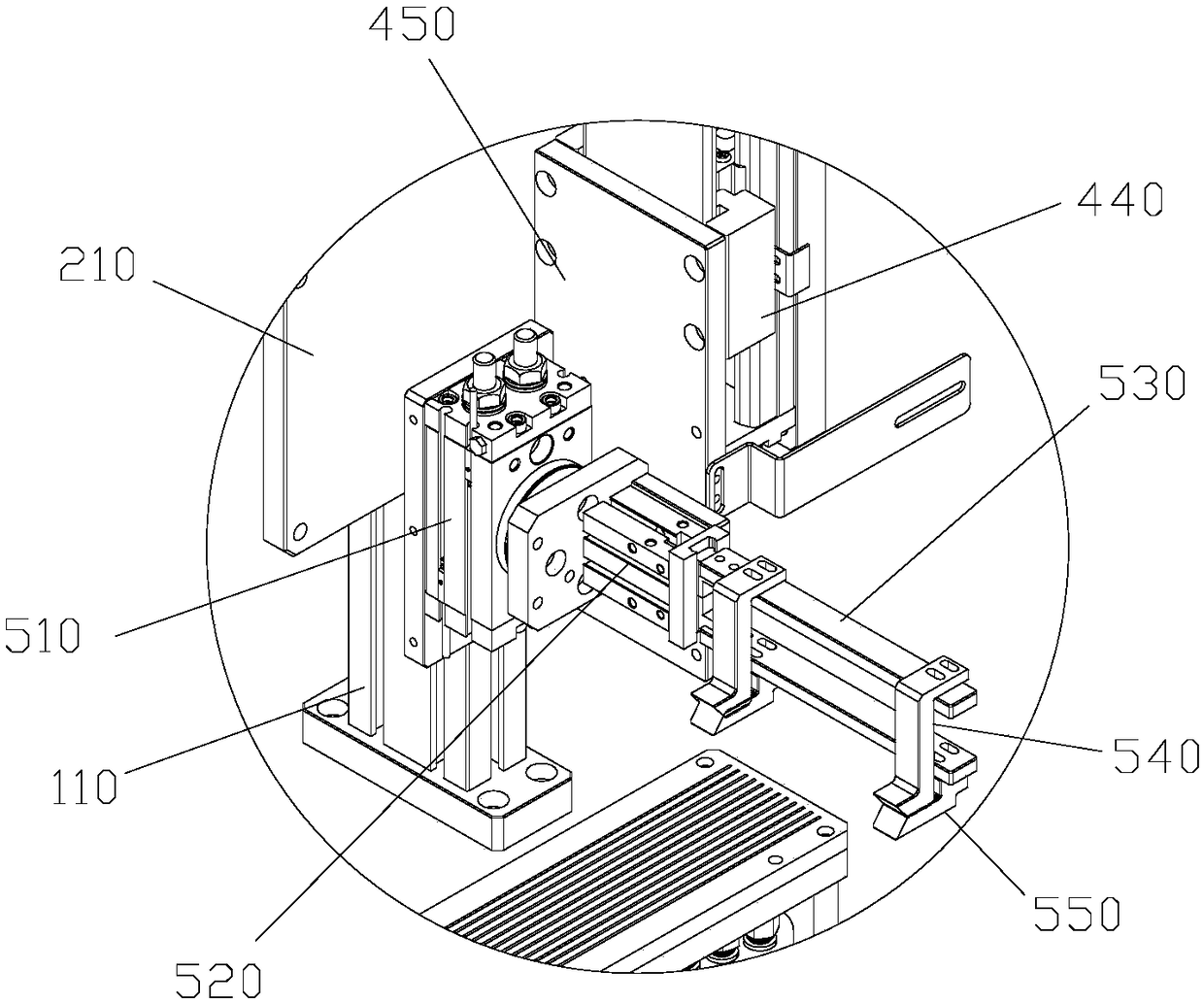

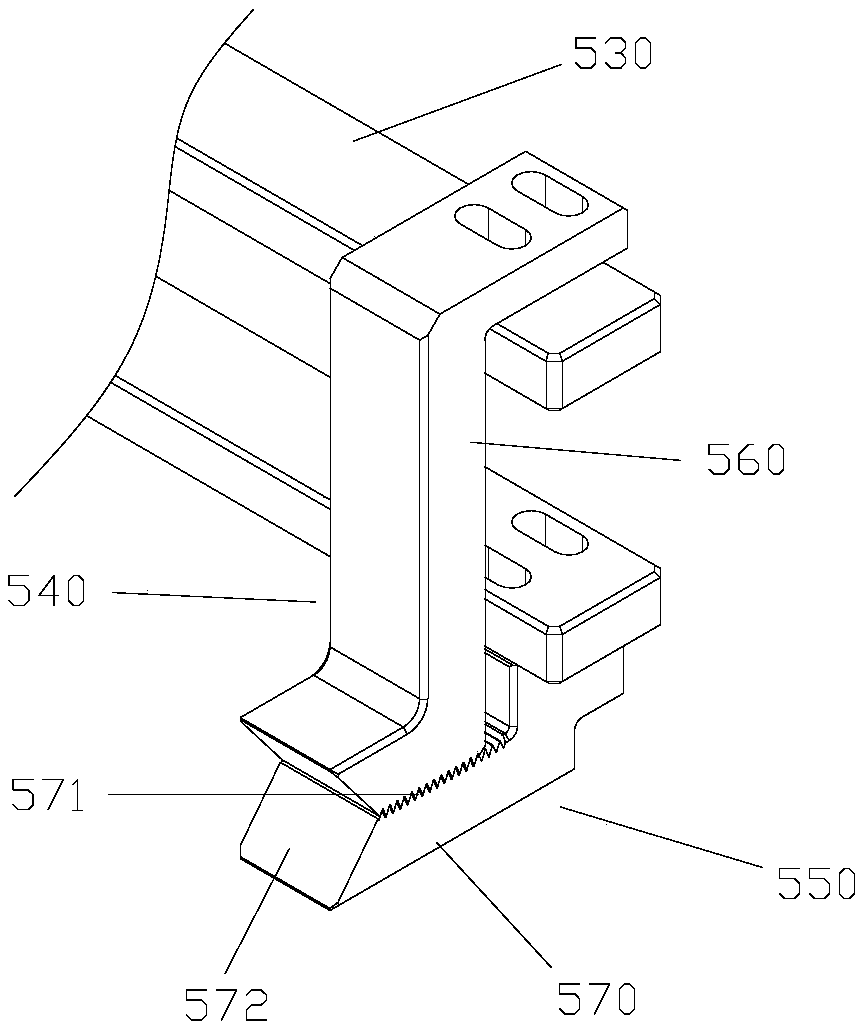

[0033] refer to figure 1 As shown, an embodiment of the film tearing device used in the adhesive tape sticking machine of the present invention is used to tear off the upper film in the sheet material to obtain the adhesive tape. It includes a pair of beam brackets 110 , a beam 120 connected between the pair of beam brackets 110 , a moving plate 300 and a clamping mechanism.

[0034] Specifically, the beam 120 is provided with an X-axis moving system for driving the moving plate 300 to reciprocate in the horizontal direction. In this embodiment, the X-axis moving system includes a first servo motor 210 and a first servo driven by the first servo motor 210. The screw mandrel 220 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com